Whenever you are building or upgrading any kind of equipment, a question of brushless vs brushed motor shows up sooner or later. It is one of those decisions that seems simple at first but ends up influencing far more than just how a machine turns or how fast something spins. The motor type that you pick can affect energy usage, reliability, operating expenses, the user experience, and even the total lifespan of the product.

Over the past decade, the demands placed on motors have shifted. More businesses now focus on performance per dollar instead of just upfront price.

The market itself is changing as well. Data shows that the worldwide market of brushless DC machines is growing steadily and is expected to reach USD 20.68 billion by 2030. This growth pattern is driven by industries that rely on long operational hours, less maintenance, and high reliability. At the same time, brushed ones continue to be widely used because they are inexpensive and easy to source.

All of this explains why understanding the difference between the two types is so important. The goal is not just to choose a motor that works today. The goal is to choose one that will support your business for a long time without creating invisible costs or consistent maintenance problems.

This guide breaks down the brushless vs brushed motor comparison in a clear and practical way.

Understanding the Difference: What Are Brushed and Brushless Motors?

Before diving into the brushless vs brushed motor discussion, it helps to start with a simple look at what these two types are. Let’s just want to understand what makes the two options different and why it matters in real business settings.

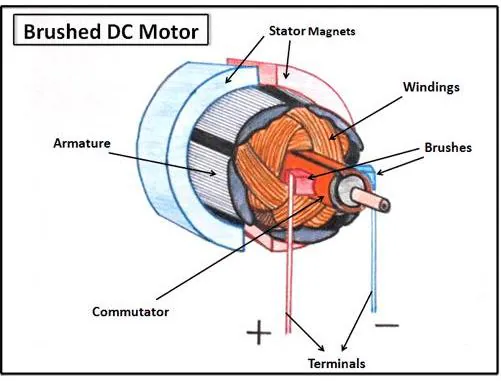

What is brushed motor?

A brushed motor is the older and more traditional type. It has been used for well over a hundred years, which is why it’s still used in many everyday products. Inside it, tiny brushes touch parts of the spinning mechanism. This touch keeps the machine running, but it also causes gradual wear. Over time, the brushes need to be replaced, and performance can decline as they age.

Because they are simple to build, brushed ones are usually cheaper upfront. This is why they remain common in low cost devices and tools. A market study noted that brushed motors continue to hold a strong position in applications where affordability matters most, especially in consumer goods and lightweight machinery.

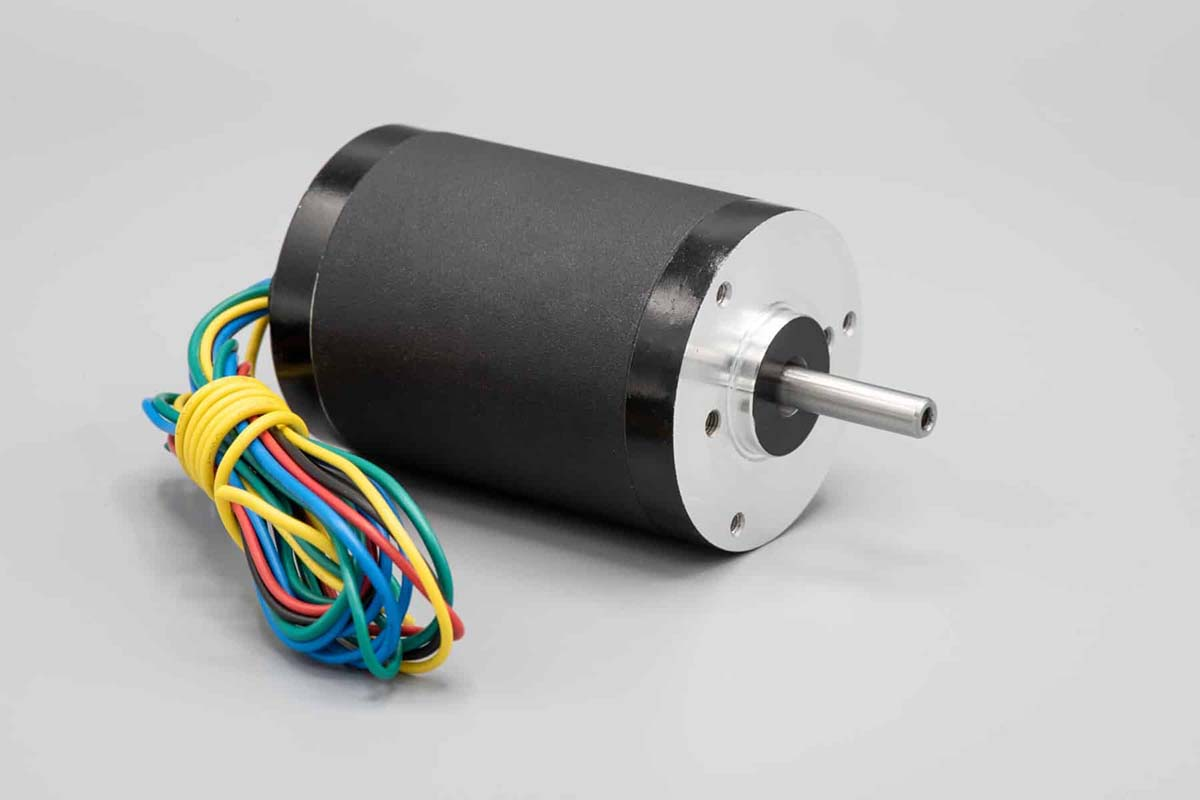

What is a brushless motor?

A brushless motor works in a different way. Instead of using brushes, it relies on electronic control to keep it spinning. With no physical contact inside it, there is less friction, less heat, and fewer components that can wear out.

This naturally leads to longer lifespan and lower maintenance. It also results in smoother and noiseless operation, which is why brushless motors appear in applications where performance and reliability matter.

Key Performance Factors That Influence ROI

When comparing a brushless vs brushed motor, most businesses care about one thing above all else. They want to know which option will perform better over the long run and which one will deliver a stronger return on investment.

Although both types can power equipment reliably, their performance characteristics are quite different. These differences often show up in day to day operations, energy bills, maintenance, and product lifespan. Understanding these performance factors helps understand why many industries are steadily shifting toward brushless technology.

| Factor | Brushless Motor | Brushed Motor |

| Efficiency | High efficiency with no brush friction – lower heat loss. | Lower efficiency during long use due to friction and heat. |

| Lifespan | Long lifespan with minimal wear | Shorter lifespan because brushes degrade |

| Maintenance | Very low maintenance as no brush replacements are needed. | Regular brush changes and cleaning is needed. |

| Speed & Control | Smooth, precise, and electronically controlled | Less precise with fluctuating speed and torque |

| Noise | Quiet and spark free. | Noisy and may produce sparks. |

| Control Complexity | Requires electronic controller, allows advanced control. | Simple to control but limited capabilities. |

| Cost | Higher upfront cost, better long term ROI. | Lower initial cost, more long term expenses. |

| Power-to-Weight Ratio | Higher power density. | Lower power density. |

| Environmental Impact | More efficient and longer lasting, reduces waste. | Shorter life and lower efficiency increase waste and energy use. |

Cost Comparison and Long Term ROI

When people compare a brushless vs brushed motor, ROI is usually the first thing that comes up. Some assume that because brushed motors are inexpensive at the beginning, they must be the better option. Others assume that brushless are the superior choice because they last longer. The truth is somewhere in the middle, and it becomes clearer when we look at cost through a full ownership lens rather than just a purchase price.

Understanding the cost difference is helpful as it’s essential for businesses that want to avoid expensive surprises later.

Upfront price

Brushed motors almost always have less upfront cost. Their design is simpler, they have been produced for decades, and they use inexpensive materials. For corporations that are creating products or equipment that only operates occasionally, this low price can make sense.

Brushless motors cost more at the beginning because they are built with more advanced components and rely on electronic control. This higher price can feel like a hurdle, but it is only the beginning of the story.

Total cost of ownership

The total cost of ownership, or TCO, looks at everything that a motor costs during its entire life. This includes energy use, maintenance, replacements, operational hours, and downtime. When it runs day after day, TCO becomes way more important than the initial price.

Energy is one of the biggest factors. Brushless motors use less energy because they waste less power as heat. This can reduce energy consumption a lot. When a machine runs eight or more hours a day, those savings compound quickly.

Another cost comes from component wear. Brushed motors use brushes that wear down over time. Each replacement requires labor, parts, and sometimes unexpected downtime. Brushless motors do not have this issue because there are no brushes to replace.

Downtime itself is often the hidden cost. A study found that unplanned downtime can cost manufacturers an average of $260,000 dollars per hour, depending on the industry. Even if your business does not operate at that scale, downtime always creates extra expenses. It slows production, interrupts customer service, and increases labor costs. A motor that fails early can create far more expense than its initial price.

The table below summarizes the cost related differences between the two motor types.

| Cost-Related Factors | Brushed motor | Brushless motor |

| Upfront price | Lower | Higher |

| Energy efficiency | Moderate | High |

| Maintenance | Frequent brush replacements | Minimal |

| Lifespan | Shorter due to brush wear | Longer due to friction free design |

| Downtime risk | Higher | Lower |

| Total cost of ownership | Higher over time | Lower over time |

Long term ROI and real world savings

To see how this plays out in real life, imagine a machine that runs eight to twelve hours every day in a warehouse or manufacturing line. A brushed one might need new brushes once or twice a year. It may also lose performance as the brushes wear down, which affects output quality and consistency.

A brushless motor, on the other hand, keeps running with fewer interruptions. It uses less electricity and maintains a steady performance level even after years of operation. Over a period of two to five years, the savings on energy, maintenance, and downtime often outweigh the price difference many times over.

Which one offers better ROI?

For equipment that runs occasionally, or for lower cost consumer products, a brushed motor can still be a practical choice. It keeps upfront costs low and can perform well under light workloads.

For commercial, industrial, or high usage applications, brushless motors almost always provide a stronger return on investment. Their efficiency, lifespan, and reliability combine to reduce long term costs in ways that brushed motors simply cannot match.

The value becomes even clearer when a business relies on consistent uptime, predictable maintenance, or energy savings across multiple machines. In these situations, a brushless motor often pays for itself through performance stability and lower operating expenses.

Practical Scenarios

Choosing between a brushless vs brushed motor is much easier when you look at real world situations. Different industries place different demands on equipment, and those needs shape which motor type offers better value. This section serves as a simple buyer’s guide so you can match your application with the right technology.

Where brushed motors still make sense

Brushed motors may be older, but they have not disappeared. They remain useful because they are inexpensive, simple, and easy to replace. In applications where cost is the primary factor and the machine does not run for long hours, a brushed motor can still be a practical solution.

Brushed motors often appear in low duty consumer products such as toys, small fans, budget friendly tools, and household items that operate in short bursts. These products are typically not expected to last for years under continuous use. The low upfront cost is the main advantage, especially in high volume consumer markets where affordability drives buying decisions.

Where brushless motors deliver strong advantages

Brushless motors have become the preferred choice for applications that require longer operating hours, quieter performance, or more energy efficiency. Their friction free design gives them a natural advantage in environments where reliability and low maintenance are important.

They have become common in manufacturing machinery, conveyor systems, injection molding equipment, and other tools that support daily operations. They are also used widely in HVAC fans, commercial pumps, electric vehicles, and medical devices. These are systems where downtime carries real financial impact and where smooth, consistent performance is a priority.

Drone and UAV manufacturers also rely on brushless because they provide higher efficiency and longer battery life. Flight time is directly linked to how effectively a motor converts power into movement, and brushless designs consistently outperform brushed ones in this area.

How to Choose the Right Motor for Your Business

Selecting the right motor for your equipment or product is not always straightforward. The choice between a brushless vs brushed motor depends on several factors, and making the right decision can have a lasting impact on operating costs, reliability, and overall performance.

Consider your duty cycle

The duty cycle refers to how often and for how long the machine will run. If the equipment operates intermittently or only for short periods, a brushed motor might be sufficient. For machines that run continuously or for many hours each day, a brushless motor typically makes more sense. Its friction free design helps prevent overheating and wear, which can extend the service life.

Assess operational requirements

Beyond runtime, consider the speed, torque, and precision needed for your application. Brushless motors excel in applications that demand consistent speed and smooth performance, making them ideal for automation, robotics, and manufacturing processes. Brushed motors can still work well in simpler applications where precision is less critical.

Noise levels are also worth factoring in. Brushless tend to operate quietly, which can improve the user experience in environments such as offices, hospitals, or homes. Brushed ones can be louder due to internal friction, but this is often acceptable for industrial or low-cost consumer equipment.

Think about energy, maintenance, and lifespan

Energy efficiency can make a big difference in long-term operating costs. Brushless use power more efficiently and generate less heat, reducing electricity bills and lowering cooling requirements. They also require minimal maintenance compared to brushed motors, which need regular brush replacements and inspection. Evaluating expected lifespan and maintenance resources can help you forecast costs and prevent unexpected downtime.

Decision tip

If long-term reliability, reduced energy consumption, and low maintenance are priorities, brushless motors are usually the better choice. Brushed motors may still be suitable for low-cost, low-duty applications, but for businesses that rely on consistent performance, the benefits of brushless technology often outweigh the higher upfront cost.

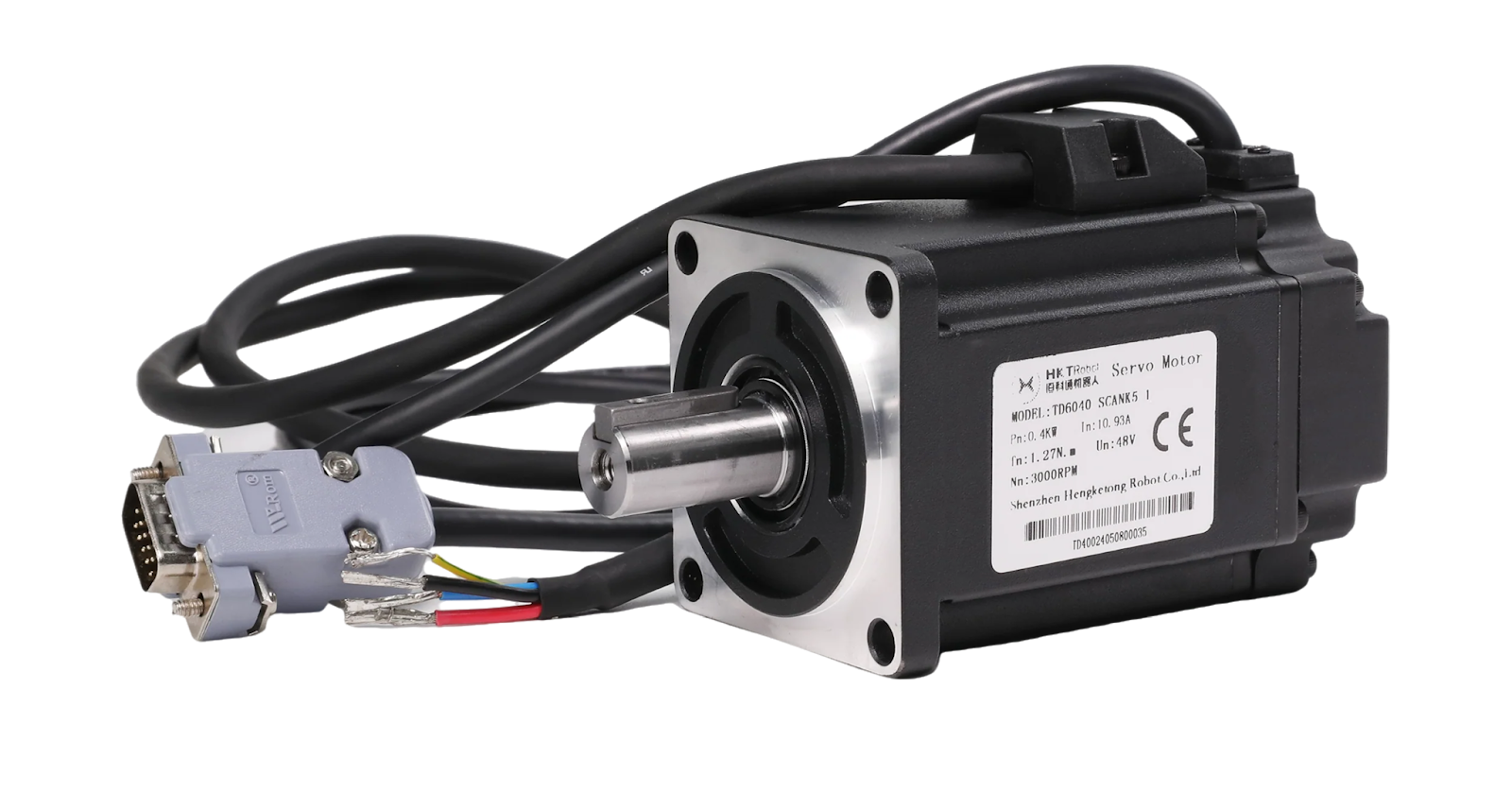

Why Many Businesses Choose DMKE for Brushless Motors

When it comes to selecting a reliable motor partner, businesses often look for a combination of product quality, variety, and support. DMKE has built a reputation for delivering all of these while focusing on modern brushless DC and servo motors. Companies across industries turn to DMKE because they need solutions that perform consistently and scale with their operations. Here are some areas where DMKE stands out:

- Wide range of options: DMKE offers an extensive catalog of brushless motors, including both standard DC models and advanced servos. This variety ensures that businesses can find the right motor for their specific application, whether it is a high-precision automation system, a robotics project, or an industrial conveyor line.

- Customization and support: Every project has unique requirements, and DMKE understands that. Their team works closely with clients to provide customization options for voltage, shaft size, torque, and speed. This hands-on support helps businesses integrate the motors seamlessly into their equipment while optimizing performance.

- Reliable quality and delivery: High-quality manufacturing and strict quality control standards mean DMKE motors perform reliably over the long term. Combined with competitive pricing and global shipping capabilities, businesses can depend on DMKE not only for great products but also for timely delivery and consistent support.

Businesses looking for brushless DC or servo motors that combine efficiency, durability, and precision often choose DMKE because of this holistic approach. Whether the focus is energy savings, low maintenance, or operational reliability, DMKE provides solutions that help companies meet their goals.

Conclusion

When it comes to the brushless vs brushed motor comparison, the choice has a real impact on business outcomes. Brushed motors are simple, affordable, and work well in low-duty applications, but they have limitations in efficiency, maintenance, and long-term reliability. For equipment that runs frequently, requires precise performance, or must operate with minimal downtime, brushless clearly stands out.

Brushless motors offer higher energy efficiency, longer lifespan, lower maintenance, and smoother operation. These factors combine to reduce total cost of ownership and deliver stronger long-term ROI for businesses. They are increasingly the preferred choice in manufacturing, automation, robotics, electric vehicles, and other modern industrial applications.

For companies designing new products or upgrading existing systems, investing in brushless DC or brushless servo motors can improve performance, reliability, and efficiency. DMKE provides a wide range of high-quality brushless motors that help businesses achieve these goals while supporting long-term operational success.