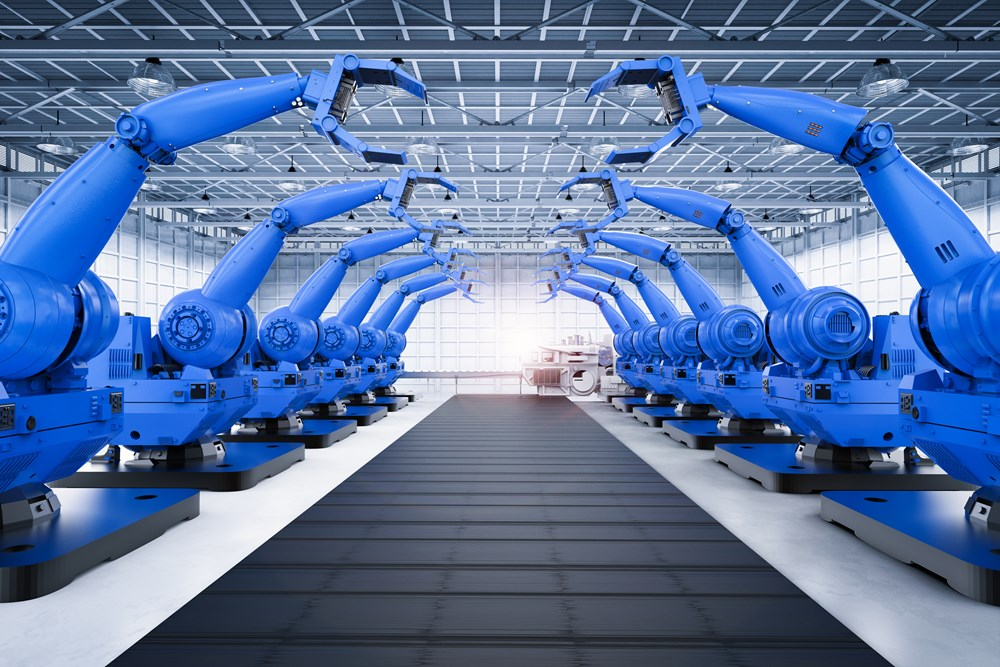

Don’t you hate it when, mid-task, your equipment fails and dramatically breaks down? It is something that everybody working in automation engineering departments can relate to. However, what many don’t know is that most of these breakdowns aren’t rooted in a big technical glitch.

Rather, they are mostly caused because you are using a motor that is not right for the entire assembly to begin with. This might explain why some conveyor belts slow down when the load on them increases, and robotic arms lose their precision after working for a long shift. It is also why many pumps overheat every other week.

All these issues are not with the mechanical components of the devices themselves. Rather, they are caused by incorrect motor selection. Nevertheless, we agree that motor definition, understanding the verb motor, and choosing the right motor for your task are not simple or straightforward. It’s not just about matching the voltages to the speed expected by you or finding a device with a fulfilling long spec sheet.

The right motor, rather, is the one that meets the equipment’s real-time workload. It goes hand in hand with the environment it works in and meets the expectations of the engineers using it. In most cases, the right one will be defined by the accuracy it provides, depending on the application demands.

The wrong motor drives the machine towards a quiet struggle at first. Once things go beyond its control, it will break down dramatically. Whether you are an engineer, industry owner, or work in a procurement department, you need proper motor skills and knowledge, as you don’t want to deal with downtimes and costly repairs at all.

This is why you need to know the right way to select the perfect motor. Below, we are going to cover each and every aspect of motor definition and selection in detail. So, let’s dive in.

What “Motor Selection” Really Means

To understand how to enhance your motor skills and selection ability, you first need to reflect on a systematic motor definition. When you think of yourself going out to choose a small motor, do you just imagine yourself choosing between the AC motors, DC electric motors, BLDC motors, or servo variants? Or do you rather want to go in-depth into what a motor does and how it suits your specific functional needs?

The truth is, real selection goes deeper into the details of the mechanical action it is meant to perform. You need to understand what the electric motor definition really implies for your equipment.

All motors are designed to serve one or two specific purposes in a specific way. While some are built to work with consistent heavy loads, others are meant to quickly alter their functionality under a quick torque burst of movements.

Some motors are meant for quiet working, while others just perform the role of low-cost basic rotation. Not selecting the right motor for the right motor output results in poorly performing equipment that doesn’t last long.

Whenever you go about selecting a motor, below are a few questions that you must be able to answer:

- What exactly will the equipment be doing all day?

You must know whether you want your equipment to lift, push, position, work slowly, work quietly, or simply rotate.

- What is the nature of load consistency on the equipment?

Some equipment, like a pump, will face steady resistance, while robotic arms might have to face changing resistance from the outside environment. Depending on what kind of resistance your equipment will face, your selection will vary. Check for speed controllers, drive density, and power source type as well.

- Do you want precision or raw motion?

For conveyor belts, you don’t really need pinpoint precision. However, with CNC machines, you cannot compromise on that. Just see what you need.

- Do you want the equipment to run non-stop consistently or in short cycles?

Knowing the duty cycle of your equipment will easily narrow down the options for you.

- How fast should the assembly accelerate or decelerate?

For heavy loads that need quick starts, you need high torque curves in your motor compared to lighter loads.

One major disruption in the selection comes when clients focus only on the differences between options based on their voltage and RPMs. The right way, rather, is to interpret the motor definition in the context of the real-life application of the equipment.

In other words, when choosing, you don’t need to look at just the big numbers, but rather the design and functionality and how it matches your purpose.

Types of Electric Motors

Things can get tricky when you are presented with multiple options to make a specific and exact selection from. Hence, before we go deeper into the details, here are some of the major types of motors that you must be aware of.

- AC Induction Motor

These are the most common universal motors found in most of the industry setups with efficient rotors. These are simple in their design and are capable of offering durability and longevity with fewer maintenance costs.

The motor housing of these devices is perfect for equipment that needs to run with long intervals or at a steady and consistent speed. AC induction units are often found in conveyors, pumps, compressors, etc. In short, anything that does not need much precise control can rely on this option.

- Servo Solutions

For applications and equipment that require quick propulsion, accuracy, and real-time positioning of the permanent magnet motors, servo solutions perfectly take the lead. You can commonly spot servo motors being used in CNC machines, AGVs, robotics, and other automated inspection systems.

- Stepper Solutions

As the name indicates, these stepper torque motors move in small and controlled steps at a consistent speed. Such a working style makes these motors ideal for equipment that needs movements in quick, exact, and well-timed increments. You can mostly find stepping motors being used in household appliances, printers, 3D developer machines, and controllers.

- Brushless DC Motors or BLDC Motors

Brushless DC motors or BLDC motors are efficient, lightweight, small, and powerful options perfect for battery-powered equipment that is compact in size. Such a device drives AGVs, Teslas, drones, robots, e-bikes, etc., and anywhere else where a stable torque is required.

- Brushed DCs

This is a simpler DC version with brushes that is affordable, extremely easy to control, and suitable for low-maintenance and cheap applications. You can find them in toys, tools, and other portable devices.

Here are some common real-life examples of different industry needs along with the motor options that are used in them:

| Equipment / Industry | Motor Type | Why It Fits |

| Conveyor Belts / Pumps | AC Induction | Steady, long-lasting motion |

| CNC Machines / Robotic Arms | Servo | Precise positioning, controlled torque |

| Packaging / Labeling Machines | Stepper / High-Speed Servo | Accurate start-stop cycles |

| Electric Bikes / Small Vehicles | BLDC / Hub / DC | Efficient, compact, controlled motion |

| Household Appliances (Fans, Dishwashers, Irons, Vacuums) | BLDC / Universal / High-Speed DC / Induction | Quiet, stable, or strong suction |

| Medical / Delivery Robots | BLDC / Stepper | Smooth, precise, reliable motion |

Performance Metrics for Motors

As we have been saying, the right motor is the one that fulfills whatever is needed from it by the equipment. An important parameter to decide the correctness of a motor for the system is its torque. In case heavier loads, more rotational force or torque are required compared to when the equipment has to perform the basic rotational functions.

Another of the critical factors is speed and acceleration. For equipment and applications where rapid starts and stops are required, servo solutions will work the best. On the other hand, for steady, long-period running, induction ones are a good idea.

You also need to look at the precision and control that the equipment demands. For machines like CNC, robotics, robotic arms, and packaging equipment, stepper and servo solutions will offer exact positioning, precise movement, and control, making them ideal.

You also need to see the power source and efficiency you want to opt for. Whether your system runs on AC or DC, an efficient motor will save energy and reduce heat generation. If you need something highly energy efficient for portable devices, going for BLDC is a good idea.

Lastly, you need to look at the environmental conditions in which the equipment will survive. For this, we suggest looking at the IP rating of the motor material. Then you can better decide whether or not it will be able to withstand the moisture, vibration, and heat it is meant to bear.

Lastly, your decision should also reflect on the cost and maintenance considerations. Universal options might come cheaper, but they will require a lot of spending later on. BLDCs, on the contrary, might be expensive, but have a longer lifespan and are low maintenance, thus saving money.

Step-by-Step Motor Selection Process

Don’t let technical datasheets and difficult jargon overwhelm you. Below is a simple and structured step-by-step approach that you can take to make the right motorised selection:

Step 1. Defining What You Need

This is the most important part of going about selecting anything, especially in bulk. Before you go about finding a solution, you need to identify what you need it for. Be clear on whether you need the motor for a conveyor belt, an AGV, a robot arm, a robotic arm, a pump, or any other packaging system.

Once you know exactly why you need an item, it gets easy to find the right variant for your needs. At this stage, it is also advisable to clearly define your requirements regarding the speed, acceleration, precision, and torque.

Step 2. Determining Load And Torque Requirements

If you haven’t done so in the previous step, it’s best to properly calculate the load amounts you want the equipment to handle through its mechanical parts. It’s always best to go a few numbers above the expected load to be on the safe side. This helps you choose a product that is capable of delivering more than enough torque for a smoother and more reliable operation.

Step 3. Deciding On Speed And Control

Now you need to see whether your system needs a consistent speed or would work with short bursts of variable speed at regular or irregular intervals. This helps you decide whether or not your motorized system should have precise positioning.

Step 4. Considering Power Source And Environmental Conditions

Now decide whether you need AC, DC, brushed, brushless, or a BLDC system based on how efficient your system has to be. If you are making a selection for a battery-operated or portable system, going for BLDC is a good idea.

Here, it is also advisable to check the environmental conditions in which the system will be working. Temperature, humidity, heat, dust, and external vibrations really play a great role in deciding what you need. Go for robust and durable options if you have to use them in industrial environments, while household and office environments often do well with noiseless and low-maintenance options.

Step 5. Evaluating Cost And Maintenance

Now that everything is clear, you can do a critical analysis of the upfront cost with its maintenance charges and upkeep requirements. Some options might be cheap, but they wear out faster and need a lot of maintenance. In such cases, it is better to consider expensive options that not just perform well but also last longer.

Step 6. Verifying Compatibility and Safety

Now that everything is done and you have a final winner, ensure that the selected motorized system will fit mechanically and electrically with the equipment it is being bought for, and also fulfill the safety standards and come with all the needed certifications, especially if you are buying it for medical equipment or industrial usage.

Common Motor Selection Mistakes Engineers Should Avoid

If you are an engineer who is going out to make a motor selection, be aware of some mistakes you must avoid at all costs:

- Not considering the torque requirements of the equipment will lead to poor performance and other similar issues. It’s a huge mistake, as less powerful systems are often overworked and break down.

- One must never prefer speed over control, because faster motors with no precision are of no use in most systems.

- Not choosing a motor considering the environment it will work in is a huge mistake that leads to quick damage.

- Efficiency and power source are important aspects of selection that, when neglected, can lead to higher costs and battery drainage.

- Not considering maintenance costs as part of the total cost of the system often leads to bigger future issues.

- Not carrying out compatibility checks from mechanical and electrical perspectives is another mistake engineers should never commit.

- Ignoring noise and vibration considerations can also lead one to buy useless solutions that don’t fit in their place.

- Not considering whether your selection matches your requirements is another selection mistake many people often make.

How the Right Motor Improves Machine Performance

By now, you must be wondering if all this fuss about the right motor selection is worth it. Well, it is one of the most underrated blessings for any system. It can entirely transform and uplift a system, how smoothly and precisely it operates, and how energy efficient it is.

With a system getting the exact torque and speed that it needs, there are no vibrations, jerks, or wear and tear to deal with. Take CNC machines, robotic arms, and other automated packaging lines as examples. Stepper and servo solutions are perfect here to provide the exact positioning, accuracy, and consistency.

Other than performance, the overall efficiency of a system is entirely dependent on the right selection, too. High-quality selections like BLDCs will consume less energy while also generating less heat while working. This won’t just reduce the operational cost but will also bring down the system’s downtime and extend its life.

Ultimately, selecting the right motor is more important than anything else for a system. If you want optimal performance, reduced costs and maintenance, as well as efficient working, you have no choice but to take your time and select the right brain for your system.

Get Expert Motor Selection Support from DMKE

Don’t let the tricky business of choosing the right motor for your equipment confuse you. Contact us at DMKE to make everything simple. We have a team of experts to provide you with the right kind of guidance and equipment tailored exactly to your needs.

For years, DMKE has been designing, executing, and distributing motorised solutions that fit one specific function exactly. Each unit we produce is made with the highest-quality components under precision engineering.

Whatever unit we produce undergoes a strict, 8-step verification process prior to its release in the market. Our customers can purchase and get custom-made solutions from us for all their needs, while being at peace with our reliable and efficient post-sales support and customer services.

From helping you select the right solutions to customizing our products and providing amazing post-sale support, DMKE has it all.

Contact us today, visit our website or leave us a message on WhatsApp to take the guesswork out of your selection process and end up with a reliable, safe, and efficient solution every time.