The evolution in the automated industries in the past 5–10 years is more than just commendable. It is safe to say that automation has not evolved as quickly as it did in the last decades. Now, only one thing lies at the heart of every industrial automation setup: the servo motor.

Whether you talk about robotic arms, pick-and-place components, CNC machines, routers, aeronautics, AGVs, AMRs, or any other thing following the principles of automation, you will find servo motors working as their backbone.

These motors are the major force behind setups where mistakes are non-negotiable, and precision is required more than anything else. Modern factories run on short deadlines with short batch sizes, with a strict demand for consistency in quality. At the same time, these factories are dealing with rising manpower shortages along with intense competition in the market. All of this ignites the pressure on these factories.

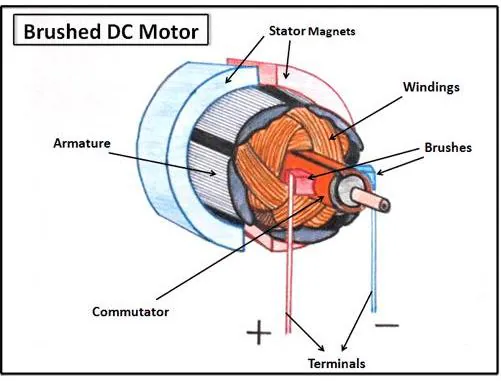

In such environments, traditional motors can simply not exist, nor can they be trusted. These motors can cause vibrations with multiple inconsistent outputs, and precision is something far from achievable with such classical systems. Hence, in industries where even the most minor speed fluctuations and displacement mistakes cannot be compromised on, servomotors are the only saviors.

What makes these motors so efficient is their accuracy and intelligence. These motors work in a closed-loop setup, which means they can constantly monitor, adjust, and correct their own performance. The connection between their controller and encoder, and their quick ability to make sense of deviations in their workflow, is what ensures faster and precise functioning from these motors.

In other words, unlike classical motors, servo solutions do not need manual intervention, as they can automatically sense and adapt their behavior whenever required. These motors are everywhere. Whether you talk about warfare, packaging, production, or IT, the existence of any manufacturing industry in these realms is simply not possible without servo motors.

If you are new to procuring motors and are not aware of the abilities of servo motors, this article is for you. Below, we are going to reflect on the top 5 servo motor applications in detail. We will also touch upon other applications and industries where servo motors are being used increasingly.

5 Common Servo Motor Applications

Thanks to the control and precision in their motion and speed, servo motors are used across a wide range of industries. Whether you talk about high-speed robots or delicate product handling equipment, the versatility of the servo solutions is undeniable. There will always be a specific servo solution for each industry and its needs.

Below are some applications of servo motors that will show how these motors have taken over multiple industries because of their precision and smart, intelligent feedback and monitoring systems.

1. Robotic Arms & High-Precision Pick-and-Place Systems

In industrial robots, even sub-millimeter accuracy is extremely important for the proper functioning of modern systems. Servo motors act as the backbone of such systems with their nanosecond and sub-millimeter accuracy, along with a real-time feedback system. These motors can ensure that every motion that a robot performs is precise and repeatable while ensuring the consistency of that motion as well.

Servo solutions are able to coordinate in multiple axes smoothly, which makes it easier for industrial robotic arms to perform complex functions without any mistakes. Servos are also responsible for the synchronized movements and jitterless working of the robotic arms despite changing external loads and conditions.

These solutions maintain consistent torque in the robots. This enables them to balance themselves and maintain their stability even when the tasks being performed are speedy, and the equipment is under high loads.

In robotic arms, each joint is powered by a servo solution. All these joints communicate with their respective controllers to ensure a well-coordinated work. The motion control algorithms in such setups work along with the motor’s encoder for proper position tracking. This helps them slow down to microscopic levels wherever needed. This way, the servos in robotic arms ensure that every placement or rotation is executed exactly as expected from the system.

The entire system runs on a closed-loop feedback control; hence, it keeps adjusting and correcting itself regardless of external disturbances, vibrations, or misalignments. This results in an accurately consistent and reliable operation on multiple axes throughout long working hours.

Robotic arms that work with servos are widely used in PCB assembly lines. In such industries, delicate components are required to be placed precisely and seamlessly. The robots used in automotive manufacturing also come with high-torque servo motors. These motors perform the task of welding, assembling, and material handling with minimal deviation in such automotive lines.

Packaging industries also use robotic arms for fast sorting, palletizing, inspection, and consistent pick-and-place operations that must happen speedily to keep up with production needs.

The consistency of servo solutions also enhances the overall workplace safety and brings repeatable results across multiple production cycles. Servo motors also reduce the need for manual labor, ultimately resulting in less chance of human error in highly demanding environments.

2. CNC Machines & Precision Machining Centres

Thanks to their ability to maintain precise positioning and accuracy during milling, drilling, cutting, and turning operations, servo motors are at the heart of almost all modern CNC machines. They can compensate for vibration, external resistance, and backlash, which makes them ideal for CNC routers where stable machining under heavy loads cannot be compromised.

The high stiffness and strong torque of servo motors also make them ideal for metalwork and high-speed production environments where precision machining appliances usually operate.

There are several types of CNC systems, mainly including milling machines that need rapid tool changes. Servo motors are also found in laser cutters. Moreover, you can find servo CNCs in waterjet and EDMs, where smooth and uninterrupted motion paths are non-negotiable for clean and accurate cutting results.

The closed-loop functionality of servo solutions helps ensure that all positionings and motions done by the CNC machine are accurate and correct. This helps these CNCs in achieving ultra-smooth finishes with minimal vibrations and deviation marks.

Because servo systems constantly keep adjusting themselves for their load, vibrations, and speed against resistance, the scrap rate in cutting is also significantly lessened. This leads to fewer finishing problems, less need for rework, and more efficient and quicker cycles with speedy product project completion.

These servo-powered CNCs are particularly important in aerospace machining, where components have to meet tight, strict demands to ensure their ability to meet tight tolerances. These solutions are also found in engine and gear manufacturing machines, where consistent shaping, drilling, and cutting are required. Servo-driven CNC systems are also found in mold and dye production, along with other glass and diamond cutting industries.

3. Conveyor Systems & Automated Material Handling

In conveyor systems and belts, it is essential for the components to maintain a precise and consistent speed across multiple stages and different production lines. Similarly, these systems require smooth acceleration and deceleration regardless of how long the system keeps working. It is also required for conveyor belts to prevent slipping, collisions, or damage, especially when they are handling delicate and sensitive products.

All of this is only possible if these systems are capable of real-time synchronization through their sensors, scanners, and other vision systems installed in them. Servo motors are hence the only backbone needed by such conveyor systems. These keep the entire material flow accurate, precise, and well-coordinated, giving the system a seamless working speed.

It goes without saying that the consistent control and feedback mechanism of servos also makes them capable of ensuring smooth conveyor belt working. There are different types of conveyor belts, and each of them is now powered with a servo solution.

Indexing conveyors, for example, help ensure exact stop-and-go motion during packaging and assembly tasks. Similarly, servos benefit smart conveyor systems with their tracking abilities so that these systems can handle items individually without compromising on their accuracy.

Servo motors are also a major driving force behind high-speed sorting conveyor belts, where rapid redirection based on product size, weight, and barcode data is required.

Servo-controlled conveyor systems are used in e-commerce warehouses where they are capable of handling thousands of parcels per hour with accuracy. Similarly, food and beverage bottling plants also use conveyor systems for consistent filling, handling, capping, and labelling of bottles.

In the pharmaceutical industry, conveyors help with clean, precise packaging while also ensuring a delicate handling of the medicines. Lastly, electronic assembly lines use conveyors for accurate component handling and sorting at high speeds.

Using servos to run the conveyor belts in multiple industries helps ensure faster work cycles with stable speeds and resists drifting. These systems require minimal maintenance and are able to automatically make corrections to their performance. Using these industrial conveyor systems helps ensure quick tasks with reduced mechanical and labor stress. These conveyors also help the factories ensure predictable cycles with better productivity and enhanced efficiency.

4. Packaging Machines (Filling, Sealing, Wrapping, Labelling)

Packaging machines and systems have to ensure synchronized motion. This motion must remain accurate and consistent, even at high speeds, regardless of the repetitive nature of the tasks. This explains why most modern packaging systems now depend on servo motors for their operation. Multiple-axis coordination is another requirement for modern packaging machines. These machines have to cut, fill, seal, wrap, and wrap everything while ensuring precise and accurate timing for each step.

Servo solutions also support quick changeovers between different SKUs or product sizes in packaging automation systems. This makes them ideal for flexible industries where manufacturing and packaging take place at a rapid rate.

There are different types of packaging machines performing different types of functions. However, each of these now mostly depends on servos for their proper working. For example, form, fill, and seal machines measure, shape, and seal packaging films with precision. Case packers utilize their seamless timing abilities for fast flap folding and box formations.

Bottle filling and capping machines also use servos’ accurate volume control for their functioning. Shrink wrappers, heat sealers, and high-speed labelers also have to maintain alignment and speed without errors during their functionality, something that servos excel at doing.

With their closed-loop feedback system, different types of packaging machines dispense product volumes with accuracy, ensuring proper filling and reducing waste. All of this happens in a perfectly aligned system that makes no compromise on the speed and time taken to complete one packaging task.

Many modern packaging machines have to end their task with high-speed bottle capping or labeling. Here, servo solutions help achieve a consistent and exact finish, regardless of how rapidly the line is moving.

Servo-powered packaging systems help packaging industries minimize their waste production, too. This is because they are capable of preventing spills and overfills, along with mislabels and sealing defects.

These systems are capable of delivering higher power output without making any compromise on quality. This helps factories switch quickly between different types of production and packaging, and ensure flexible yet consistent working through multiple batches, regardless of how big or short they are.

5. AGVs (Automated Guided Vehicles) & Autonomous Industrial Robots

Modern automated guided vehicles (AGVs) have to control wheel rotation and maintain a consistent speed across various floor conditions. They also have to navigate tight paths and turning points with accuracy while dealing with changing loads on them. All of this requires the kind of precision and control that only a servo system can ensure.

Precision steering and other functions that these motors are capable of help AGVs work seamlessly. They also help the vehicle make tight turns and navigate narrow aisles safely without dropping the equipment. Servos also help such AGVs smoothly accelerate and decelerate so that the load on them remains stable and doesn’t trip.

AGV drive wheels use the same system for forward and reverse movements with proper speed regulation. Similarly, the lifting and tilting platforms on AGVs also use servos for secure load positioning. These motors also help robotic mobile bases and navigation joints in AGVs and other automated movement systems to maintain balance, precision, and discrete mobility.

In automotive factories, AGVs deliver parts between multiple stations while ensuring consistent timing. Distribution and assist centers also rely on servo-driven AGVs for autonomous pallet movement and sorting. These AGVs are also used in chemical and pharmaceutical plants, along with other hazardous and sensitive material manufacturing facilities. In hospitals, servo-driven AGVs help deliver medication, linen, and equipment seamlessly and as quickly as required.

In this way, servo-powered AGVs help ensure higher accuracy, repeatability, and safety compared to manual handling. They also minimize the chance of failure and mistakes while operating throughout the day without any fatigue, thus reducing labor dependency and long-term operational costs.

Other Emerging Servo Solutions Applications

Other than the above five applications, below are some other places where the usage of servo solutions is becoming more and more common:

- In modern textile machinery, servo solutions help ensure precise yarn tension and control fabric movement for fine printing.

- The semiconductor manufacturing industry heavily relies on servo-driven handling systems to mitigate the risks of even microscopic deviations that might cause defects in production.

- High-resolution printers and 3D printers also use servo solutions for flawless alignment of the machine components and smooth position control for color consistency.

- In machine vision inspection systems, servo motors help achieve micro-level positioning with seamlessness, aiding rapid and reliable defect detection.

Upgrade Your Automation with DMKE Servo Solutions

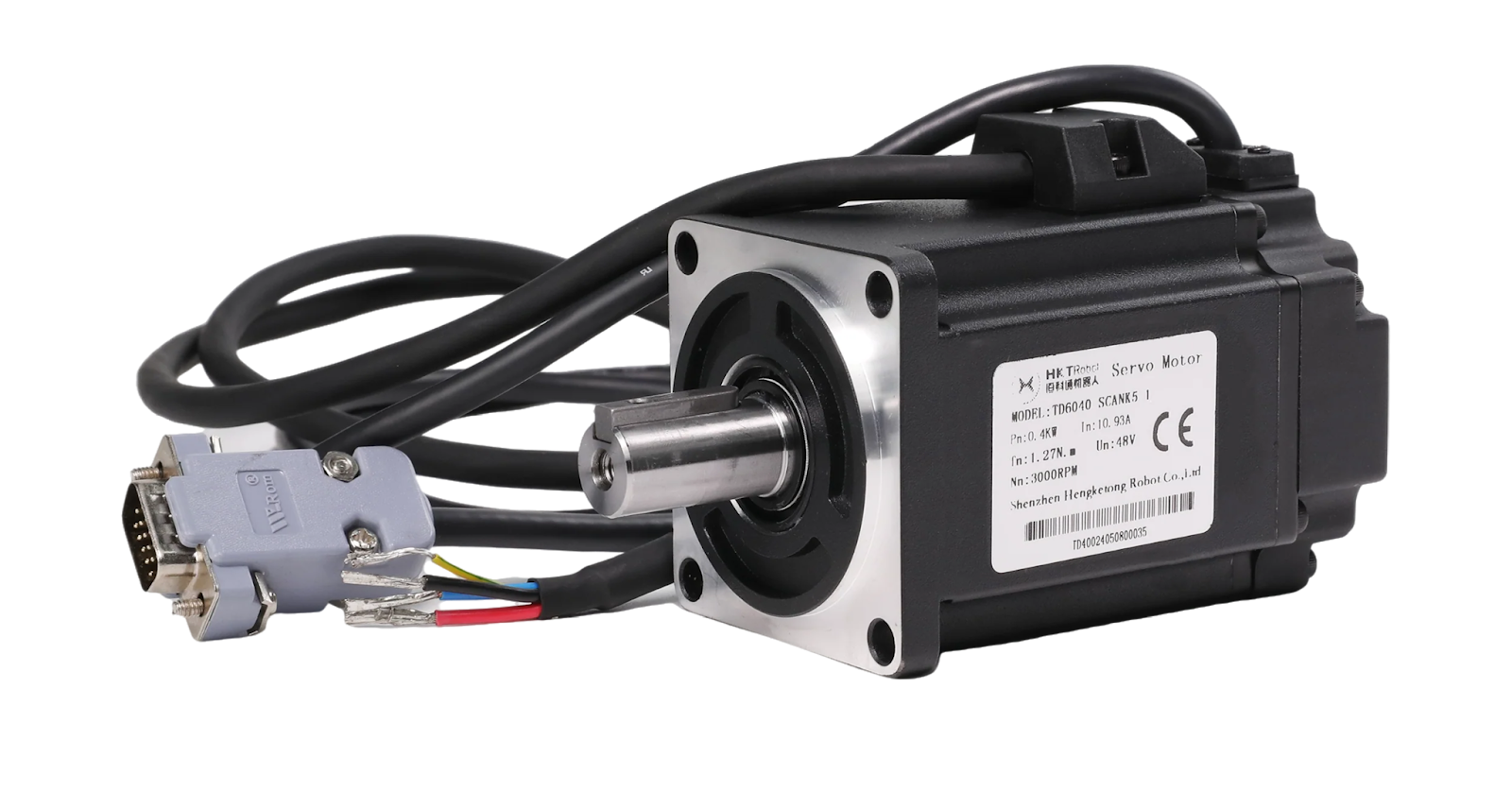

Whether they are present in the automotive sector, CNC machines, robotics, or other packaging lines, the reason for using servo motors is quite clear. These systems ensure precision, reliability, and reduce the chance of mistakes like no other. This is what makes them extremely important for modern fast-paced industries.

With automation becoming increasingly common and production setups demanding more, factories have to rely on rapid adjustments while handling variable loads and 24/7 operations. The DMKE solutions are here to help you achieve all of this with ease.

At DMKE, we are engineering servo solutions for high-demand environments. Our motors help bridge the distance between strict requirements and perfect deliverables. These solutions are capable of delivering everything with quality and accuracy while also reducing manual mechanical stress and the chance of error.

At DMKE, our experts have crafted high-quality servo solutions that are readily available for sale. Other than that, our experts can also discuss and help craft custom motorized solutions depending on your requirements, using high-quality components that are engineered to ensure performance.

Each of our motorized products undergoes an eight-step quality testing process before it is made available for sale. This speaks volumes about how seriously we at DMKE take our products and their quality.

Visit our website and connect with us today to get your hands on the best and most accurate servo technology that meets your needs without any flaws.