Imagine your work efficiency is dependent on an AGV. How would you feel if that AGV constantly hesitates at narrow turns, loses its speed when the load on it increases, or simply trips every hour? Would you like these hiccups to ruin your workflow? Certainly you won’t.

As smart as it may sound to have an AGV at your workplace, if it is not working properly, it is of no use. A poorly powered AGV setup is going to turn long-time customers into irritated visitors. It will also disrupt your entire workflow with unforeseen downtimes.

This not only brings a lot of frustration for those working with AGVs, but also inflicts additional cost for continuous maintenance and losses due to downtime.

While many don’t know, this entire problem is generally rooted in one thing that can easily be controlled. This is the system that drives that AGV. Simply stated, using the wrong motor in an AGV can single-handedly cause all these issues. This explains why picking the right mechanical controller for any AGV is so important.

In this guide, we will walk you through the right way of selecting a motor brushless DC setup for AGVs. These motors are usually meant as the ideal choices for most automated systems. These are perfect for systems that have to navigate narrow turns and deal with changing loads.

Don’t worry, we are not going to get too deep into theoretical and technical details. Rather, we will focus more on what matters in the real world. We will start with a basic explanation of a motor brushless DC setup, and why it is so essential for an AGV.

Then we will discuss a few important key requirements for the ideal working of any AGV, followed by a stepwise guide on selecting the right AGV motor. Consider this guide as your practical playbook crafted by an engineer who wants you to succeed at your next AGV motor selection.

What is a Brushless DC Motor?

Like every other motor, a brushless DC setup also converts electrical energy into mechanical energy. However, what makes it different from other classical versions is the way it carries out this conversion.

A motor brushless DC setup uses electronic signals and switching instead of physical components to create the rotation inside its assembly. While a brushless motor works, the windings inside the motor stay fixed. There are no brushes to disrupt the magnets while they spin, and a controller handles all the timings.

Such a design not only makes the entire working smoother and noiseless, but also removes the friction that causes wear inside a brushed motor. This design also ensures a predictable output, especially while the device that is being run on it has to move at low speeds or change its direction without glitches or jerks.

In classical motors, brushes tend to wear out quickly, which results in these motors either failing to work or requiring consistent maintenance. In brushless setups, however, there are no brushes, and hence the entire assembly remains efficient for years and doesn’t trip under consistent working.

An efficient brushless setup promises consistent torque despite the changing outer loads and under all kinds of conditions. There is no energy being lost as heat, and hence the torque remains steady throughout the working shift.

For AGV designers, this blend of stability with undisrupted long hours performance, along with a low maintenance setup, is no less than a gift. It makes a brushless motor an ideal choice for AGVs and other setups where changing loads and consistent work hours are common.

Why BLDC Motors Are Ideal for AGVs?

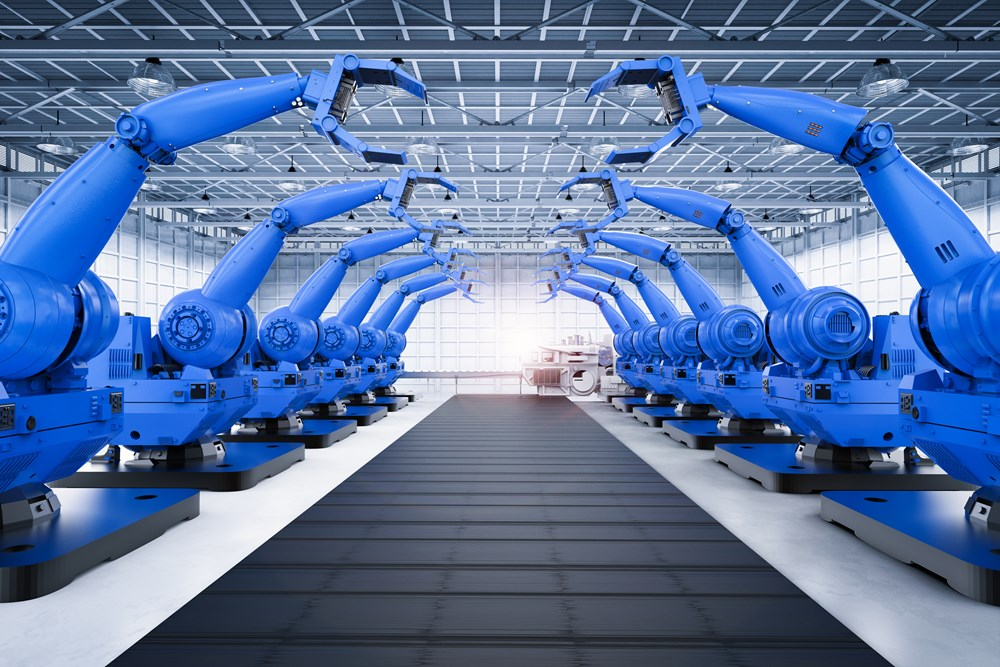

To understand why motor brushless DC setups are ideal for AGVs, you first have to try and imagine the kind of environment an AGV is meant to work in. It is a blend of non-stop motion, tight corners, narrow pathways to navigate, and consistently changing loads.

All of these things are what a brushless setup is meant to handle seamlessly. These efficient setups offer advantages like none other. In brushless setups, less energy is wasted during conversion, which ultimately results in longer operation hours per charge.

This reduces the need for an Automatic fleet to keep going back to the docks for charging. Along with this efficiency, a brushless mechanical controller also offers stability in terms of torque to the appliance it is running.

This means that your Automated vehicle won’t slow down, shudder, or hesitate, no matter how much load you keep adding to it or when it has to climb inclines. Because there are no brushes to offer resistance or wear out, these motors naturally have a longer lifespan compared to the brushed ones.

Inside the assembly of a motor brushless DC setup, there is minimal physical contact between the elements, thus reducing dust buildup, friction, or sudden failures due to degradation. This directly translates into fewer interruptions and downtime with no emergency maintenance calls to worry about.

The structures of brushless motors also make them low-maintenance in day-to-day operations. Instead of periodically replacing the brushes, engineers simply have to check the bearings and wiring to ensure the proper working and stability of the motor. Compared to replacement, these tasks are quite quick and predictable.

Lastly, it is important to note that most of the brushless DC setups are quite compact and portable, which also makes them lightweight. This helps manufacturers to keep the vehicle as small as they want without worrying about how they can deliver the needed torque for traction or lifting.

All in all, BLDC motors are a perfect force to run an AGV. These motors meet all the expectations of an AGV operational team, including efficiency, longevity, stability, and reliability in a portable body.

Key Performance Requirements in AGVs

While choosing a motorized powerhouse for any AGV, the final decision is made based on a lot of parameters that define how well your selection matches the AGV performance demands. Below, we are going to discuss a few things that one must look for when specifically choosing a motorized system for AGVs:

The first and most important thing is torque. Here, you look at both the starting torque that is needed to get a heavily loaded vehicle moving, along with looking at the continuous and peak torque that the motor can provide.

Peak torque is essential to keep the Automatic Guided Vehicle going smoothly for hours during longer work shifts. A motor with undershooted torque will simply lead to a vehicle that drags, stalls, or overheats every few hours.

Another important factor to consider is the speed. Here again, you don’t have to consider the top speed only. Rather, you must also look at how consistently the motorized interior can help a slow-moving AGV move at a controlled pace.

Most of the time, your Automatic Guided Vehicles will move slowly while navigating tighter paths. Hence, it is important to go for a motor that delivers stable RPM and won’t cause any jitters.

Load capacity also plays a central role in deciding whether or not a motor is perfect for an AGV. With the increasing payload, the demand for torque and speed changes quickly. Here, a controlling system that delivers stable performance regardless of the load on the AGV wins.

You also have to look at the duty cycle of the system. In simple terms, you have to see how long it can run under load before it needs a break. In the real world, Automatic Guided Vehicles operate throughout the day, taking continuous long-hour shifts.

Hence, motors brushless DC setups are perfect because they can handle longer operation times without overheating or needing a recharge.

Lastly, precision control of a motor is also important. It keeps the AGV safe and gives it a predictable performance. Your AGV must be able to tune its speed, make adjustments to its acceleration, and ensure a smooth deceleration throughout its working tenure.

All of this is dependent on how powerful and precise its motorized interior is. This precision control is one of the biggest reasons why BLDCs dominate most AGV designing processes.

Selecting the Right BLDC for an AGV – Stepwise Guide

Selecting the right kind of BLDC for an AGV means getting your hands on a system that matches the requirements of an AGV in the real world. Below are the steps you can follow to get your hands on the best BLDC setup for your Automatic Guided Vehicles.

Step 1: Understanding the Torque Speed Curves

For any selection, it is important to understand how it will behave under the load. You need a high starting torque for the smooth starting of loaded Automatic Guided Vehicles. You also need stable, continuous torque to ensure long-time runs.

However, both these torques should have enough margin so that the vehicle is not always operating at its limit. It’s best to go for an option that offers around 20-30% of torque margin.

Step 2: Matching Voltage to your Vehicle’s Battery System

Depending on its design, your Automatic Guided Vehicle might run on 24V, 36V, or even 48V. Getting a motorized setup that doesn’t match your AGV’s native battery voltage leads to several conversion losses. Your motors brushless DCs will perform the best only when their voltage range aligns directly with the AGV housing.

Step 3: Defining the Right Power Rating (W or kW)

This power rating determines how your AGV can accelerate, climb small inclines, and maintain a smooth operation regardless of the load shifts and the path it has to follow.

A motor with a high power rating will ensure stronger acceleration despite the load, quick reacceleration once the speed has dropped, and low heat generation.

Don’t go for a very high power rating because it increases the overall costs. It is best to choose a mediocre power that meets the continuous and peak needs of your AGV.

Step 4: Choose the Correct Control Options

The controller is the brain of the motors brushless DC setups, and hence, you need to be very careful while choosing it. For an AGV, the controller must have the right kind of speed control modes so that the Automatic Guided Vehicle can smoothly navigate at low speeds.

The controller must also have torque control for traction and steering, along with versatile braking modes including regenerative, dynamic, or mechanical ones.

Your AGV has a specific control architecture, and the controller’s communication interfaces must match it. Carefully selecting the right controller ensures that the AGV won’t jerk, overshoot, or drift from its position.

Step 5: Check Motor Form Factor & Mounting Fit

No matter how good your selection is, if it doesn’t fit well into the AGV’s body, it is of no use. Before making your purchase, make sure to confirm the shaft dimensions, mounting holes, frame size, and alignment of the wheel hub and gearbox. Ensure that it can fit into your AGV.

Most of the BLDCs are generally compact and portable, and can easily fit in all kinds of AGVs. However, it is still important to confirm before making a final decision.

Step 6: Evaluating Heat-Related Performance

Since Automatic Guided Vehicles run in longer shifts, overheating could be a major problem. Before finalizing any motorized setup, it is important to check its continuous current ranges along with its maximum temperature and cooling needs. Also, check the way it cools down.

A motor that can stay cool and can be cooled without the use of external interferences is the one that is best for AGVs

Step 7: Evaluate Efficiency vs Battery Runtime

Lastly, if you have narrowed down to a few similar options, this could be a point that helps only one stand out. Only go for a highly efficient motor by looking at its runtime, charge cycles, and operational costs.

Following the above steps, you can easily rule out most of the options and narrow down to what exactly fits your vehicle’s demands the best.

Understanding Motor Controllers for BLDC Motors

The role of the controller in the right performance of any motors brushless DC setup is undeniable. These controllers are actually the reason why a motor behaves in a way it should.

A controller can be understood as the brain of a motorized assembly that handles all the electronic commutation. It reads the feedback and makes corrections in real time. A controller also defines the time for the switching of currents inside the assembly to allow for a smooth rotation, despite the absence of brushes.

Speaking strictly in terms of an Automatic Guided Vehicle, the smoothness that this controller provides matters a lot. The controller regulates the speed of the AGV when it is working at low speeds. The same controller also enhances the AGV’s speed whenever high-speed working is required.

This controller is what maintains a proper torque, ensures steady acceleration and deceleration, and keeps the maneuvering smooth despite the changing loads. Not just that, but the controller also protects the AGV system by consistently monitoring for issues like overheating, overcurrent, or voltage dropping.

All of this explains why the right kind of controller is important for a BLDC motor and why, without it, even the best motor will be inconsistent and of no use for an AGV.

In Automatic Guided Vehicles, the controller must be able to communicate in real time with itself and correct its actions on the basis of the feedback it receives. Different controllers will use different communication methods, including CAN-OPEN, RS-485, or MODE-BUS.

Depending on what communication method a controller uses, keeping the entire working of the motorized assembly in sync with the AGV’s navigation is what makes it accurate.

Another important responsibility of a controller in AGVs is the monitoring of brakes. In AGVs, smooth deceleration is important to ensure the safety and efficiency of the workflow.

Good BLDC controllers are able to support such smooth braking and return energy to the battery without losing it in the form of heat whenever an AGV stops or moves at a slow speed. With a well-tuned controller controlling the braking, the AGV will ensure precise stopping without overshooting or tripping.

Get BLDCs That Run AGVs Like Never Before – Connect With DMKE Today!

At DMKE, we are offering all AGV manufacturers and engineers multiple reliable and hassle-free motors brushless DC setups that meet their needs the best.

All our experts can help you find the perfect match for your AGV while offering ready-made as well as custom motor solutions tailored to your needs.

Every motor that we produce uses quality components and goes through rigorous 8-step verification before being handed over to the clients, which vouches for our excellence.

Our technical team is ready to provide you with all kinds of practical guidance that you would need to select the right motor, along with installing and using it post-sale.

Visit our website or contact us through WhatsApp. Join our network of a globally wide client base that benefits from countless motorized solutions by DMKE every day.