Imagine energetically starting a motorized project, only to be forced to stop midway. The reason? Nothing else but the fact that your motor isn’t performing exactly how you expected it to. The motor may sometimes overheat, run very slowly, glitch too much, or fail under changing loads.

All of these frustrating problems can not only lower your enthusiasm toward the project. Rather, these also add extra costs and cause delays in project timelines. This is especially a problem in industrial setups.

For engineers, hobbyists, procurement professionals, and industrial buyers alike, choosing the right unit is a key factor. It is what ensures the successful completion of any kind of project. However, as easy as it may sound, choosing the right option is not straightforward. It is a decision many struggle with when trying to make an informed choice.

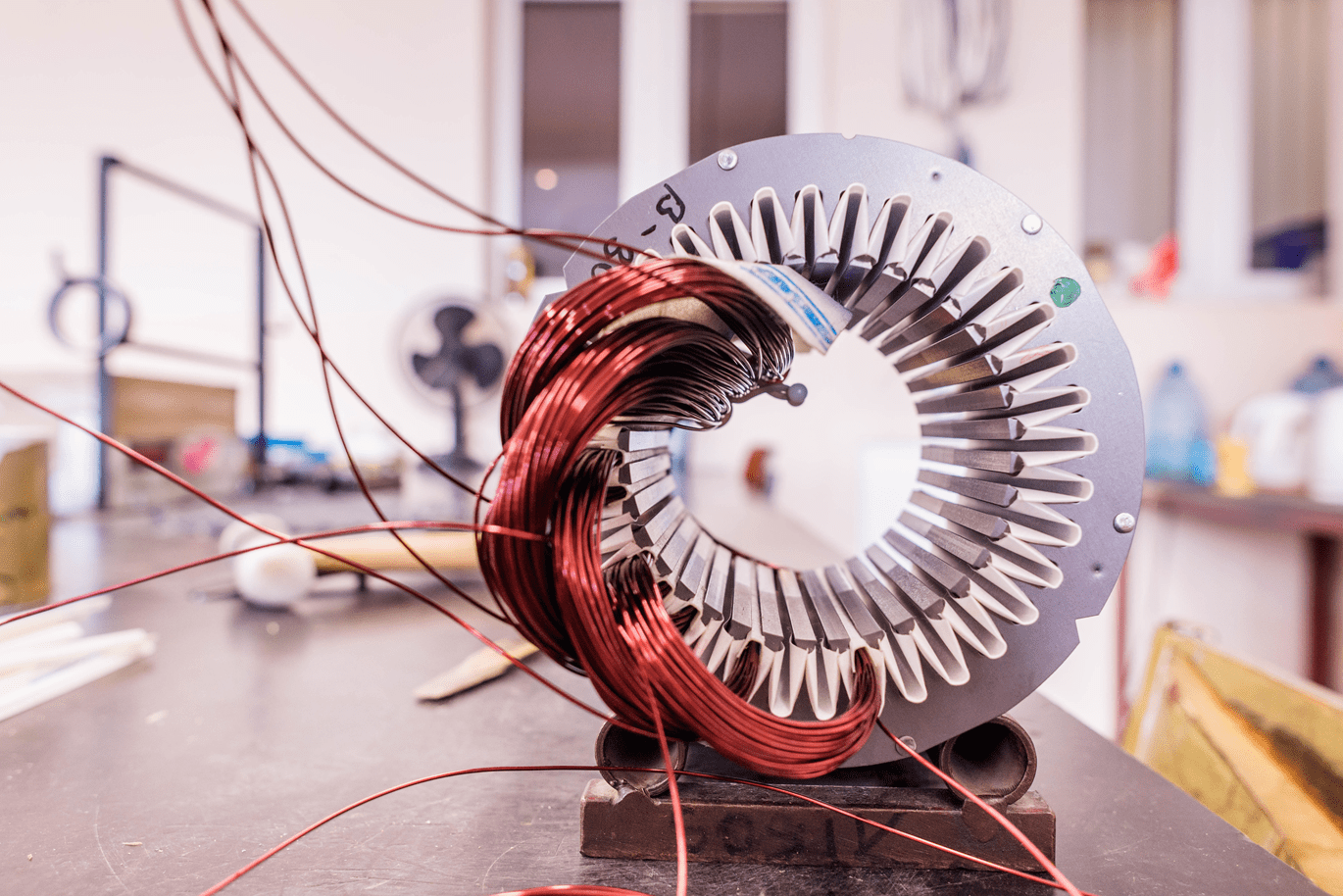

A brushed Direct Current motor is widely used across industries, ranging from simple to highly complex ones. Whether you want to build a simple robotic arm or ensure the smooth production of a vacuum cleaner, you need a high-quality brushed DC.

A brushed direct current motor typically features a simple design. It offers reliability and cost-effectiveness without demanding extensive maintenance. While these points make it an attractive option, not all DCs are equal. Factors such as voltage, current, the ability to maintain speed, and torque matter a lot.

Moreover, the quality of brushes and suitability for the environment play a significant role in defining the overall performance of a brushed DC motor. When purchasing, ignoring these aspects can lead to selecting a faulty motor. Such a motor breaks down frequently and requires excessive maintenance.

Another important factor that many people overlook when sourcing a motor is the reliability of the supplier or manufacturer. Ensuring that your motor is manufactured and sourced by a trusted party eliminates much of the guesswork involved in motor selection.

Below, we will guide you through the essential selection criteria, along with how to find a reliable motor supplier. We will also highlight common mistakes that must be avoided during the supplier selection process. By the end, we are confident that you can secure a motorized unit that not only meets your technical requirements but also delivers long-lasting performance.

So, read on!

Applications of Brushed DC Motors

Before we discuss the things you should know before purchasing a brushed direct current motor, it is important to briefly touch upon the applications of brushed DC motors. Understanding where these motors are used helps ensure that you invest in the right option and allows you to better grasp the core elements of such motors.

Firstly, brushed DC motors are widely used in industrial automation systems. These motors are the primary power source behind conveyor belts, packaging machines, assembly lines, and other automated systems that operate in repetitive cycles.

A brushed direct current motor’s ability to provide precise control and reliable torque under changing external loads makes it ideal for consistent tasks that require precise motion. Such motors help manufacturers maintain efficiency and reduce downtime.

Brushed direct current motors are also extensively used in robotics, particularly for driving wheels, arms, actuators, and other components. Since these come in compact sizes and offer ease of control, engineers can design portable and lightweight robots for a wide range of applications.

In addition, gebürsteter Gleichstroms are commonly used in the automotive industry, where they ensure the smooth functioning of various vehicle operations such as windshield wipers, power windows, seat adjustment mechanisms, and cooling fans. They offer reliable performance along with easy installation and cost-effectiveness, making them a preferred choice for automotive and spare parts manufacturing industries.

Brushed DCs are also commonly found powering many everyday household appliances. From vacuum cleaners to blenders and mixers, and from electric fans to hair dryers, brushed DCs form the backbone of most household devices. Their simple design, lightweight construction, and durability make them ideal for affordable consumer appliances.

Among the many applications of brushed DCs, their use in medical and laboratory equipment cannot be overlooked. These are often found in pumps, diagnostic machines, and other small laboratory equipment. Their precise control and smooth operation make them suitable for handling delicate tasks with minimal noise while ensuring reliable and consistent performance in critical environments.

Important Selection Points Before Purchasing

Selecting the right brushed direct current motor is often the major difference between a successful and a failed project. Whether you need a setup for industrial machinery, a robotic application, or a simple DIY home appliance, choosing the right unit is extremely important.

There are several factors you can evaluate to make an informed motor selection decision. Below, we explore some of the most critical aspects you should consider before purchasing a brushed DC.

- Voltage and Power Requirements

Voltage, overall power ratings, and current ratings are the most fundamental aspects to consider when choosing a brushed DC. Using a motor with Spannungswerte that do not match your region’s available power supply can lead to underperformance. Similarly, selecting one with excessive voltage can cause overheating and rapid damage to brushes and windings.

Current rating is equally important. It must match the load the unit is expected to handle to prevent excessive energy consumption or electrical stress.

Power, measured in watts, directly affects how efficiently a motor can drive the intended application. If you need an option for a high-speed, continuous application, you will require a unit with higher power compared to one used for a simple toy or a lightweight task.

Understanding these parameters ensures that you select an option compatible with your application’s requirements and performance expectations. Whether your project requires low-voltage precision or high-voltage industrial power, correctly matching voltage and current requirements is the first step toward finding a reliable solution.

- Speed, Load Considerations, and Torque

Once you have selected a unit that meets your power and energy requirements, the next factor to evaluate is speed. Speed, measured in RPM, along with torque output, determines how well a brushed DC can handle the demands of a specific application.

High-speed units are suitable for lightweight applications, but they may struggle under heavy loads. Similarly, high-torque options are essential for load-intensive applications, and selecting insufficient torque can lead to poor performance or failure.

It is important to assess your application’s Lastprofil and choose a unit that can comfortably manage those demands.

- Motor Size, Dimensions, and Mounting

Depending on the application, you may require a compact and portable motor or a larger unit where size is not a major constraint. Some applications demand motors that are easy to handle and fit into tight enclosures, while others allow for more flexibility in size.

Physical dimensions, shaft type, mounting style, and overall fit are important considerations that you must never overlook. A motor that is too large may not fit into the assembly, while one that is too small may fail to deliver the required torque.

Therefore, understanding your mechanical constraints and performance needs is essential before making a final selection.

- Environmental and Operating Conditions

The conditions under which a brushed DC operates play a crucial role in its performance and lifespan. This makes them an important factor to consider when selecting the right motor.

You need to understand the temperature range that the unit can safely handle. Different brushed DCs are designed to operate under different environmental conditions. In some applications, motors are exposed to extreme heat, and unless their internal components are made from heat-resistant materials, they may fail to perform reliably.

Ähnlich, exposure to dust, dirt, and moisture can accelerate wear, corrosion, and rusting, eventually leading to failure. Motors operating in such dusty and poor environments must feature appropriate housing, sealing, and overall build quality.

Duty cycle is another critical consideration. Whether the unit is required to run continuously or operate in intervals determines the heat management system that will be most suitable for your application. Selecting a unit without considering its duty cycle can result in overheating and reduced lifespan.

- Brush Life and Maintenance Expectations

The brushes in brushed DCs are typically the first components to wear out, directly impacting performance and maintenance schedules. In high-duty applications where motors operate at high currents and under significant loads, it is essential to choose motors with high-quality brushes that resist rapid degradation.

Understanding the brush quality, expected lifespan, and maintenance requirements of a motor helps you plan maintenance effectively, minimize downtime, and control long-term operating costs.

How to Evaluate Brushed DC Suppliers?

Choosing the right supplier to invest in a brushed direct current motor is just as important as choosing the right unit itself. Sometimes, even the highest-quality option can underperform. If a unit is not sourced from the right supplier, you can end up losing all the money you invested in it.

On the other hand, the right supplier will ensure that you receive a solution that is dependable, long-lasting, and worry-free in the long run. A reliable supplier helps ensure that you get the right return on investment from your unit.

Evaluating whether a supplier is ideal for procuring your brushed DC solutions is not complicated. You simply need to look at a few key aspects before investing, and you are good to go.

Firstly, you should ask your supplier for certification, testing, and quality standard documents. These factors alone help differentiate a reliable supplier from an unreliable one. A reputable supplier will always have certifications and proof of compliance with recognized industry manufacturing practices.

Some common examples include ISO-9001, CE marking, und RoHS compliance, which indicate that the supplier consistently manufactures high-grade products and ensures they are safe to use.

Additionally, many suppliers, such as DMKE, conduct in-house testing of their units for torque, speed, voltage, accuracy, and durability. Such test results further demonstrate their quality control processes.

Asking for these quality and performance test reports helps ensure that the brushed DC you are investing in will meet your expectations. The presentation of such certifications and test data also builds buyer confidence and reduces the risk of investing in defective products.

Another important aspect to clarify before investing in an option is the practical details. These include lead time, minimum order quantity, and after-sales support offered by the supplier.

If you plan to procure motors in bulk or for long-term projects, it is essential to work with suppliers that offer short lead times and maintain a consistent supply chain. Some projects may also require suppliers that provide flexible MOQs.

After-sales support typically includes technical assistance for installation and usage, as well as warranty and replacement services. These factors ensure that any post-installation issues are resolved quickly, minimizing downtime on your end. While these considerations may appear simple on the surface, evaluating them thoroughly helps you select the most suitable supplier for your specific needs.

Another key consideration is whether you want to source your units domestically or internationally. Both options have their own advantages and disadvantages.

Domestic suppliers usually offer faster shipping, easier communication, and lower logistical complexity, making them ideal for urgent projects and complex custom requirements. However, in some cases, it may be difficult to find a domestically available motor that fully meets your needs.

In such situations, overseas suppliers can be a good option, particularly for more competitive pricing. However, overseas sourcing is most suitable when time constraints are flexible.

When choosing between domestic and overseas suppliers, it is important not to consider only the motor’s base cost. You should also factor in shipping charges, delivery timelines, import regulations, duties, and other associated costs. This detailed evaluation helps you make a more informed and cost-effective decision.

Before finalizing your supplier, it is critical to ask a few key questions to minimize risks and uncertainties. Below are some important questions you should ask before making a final investment decision:

- What quality certifications do you hold for the specific unit under discussion? Can you provide test reports or performance data for this product?

- What are your standard lead times, minimum order quantities, and shipping methods? Do you offer custom solutions or OEM and ODM services?

- What after-sales support and warranty options are available with each product you sell?

Asking these questions and clearly understanding the answers helps you assess a supplier’s reliability, commitment to quality, and whether the relationship extends beyond just the initial purchase.

7 Recommended Brushed DC Motor Suppliers

Below, we are going to share the top seven recommended brushed DC suppliers that you can trust. Almost all of them are known globally for their reliability, expertise, and customer support.

1. DMKE

DMKE is a leading manufacturer of brushed DC, brushless DC, und Servo solutions. DMKE is known for its precision engineering and the quality components used in the manufacturing of all its units. We also offer extensive customization opportunities, allowing you to get a unit made exactly according to how you want it to perform.

DMKE has a strong global reputation as a supplier, along with its eight-step rigorous testing and verification process for each unit produced. Such things make us one of the most reliable suppliers in the market. Additionally, DMKE offers OEM and ODM services, technical support, and globally compliant quality standards like none other.

2. Maxon

Maxon Motors is renowned worldwide for its high-precision brushed and brushless DCs. Their products are widely used in robotics, aerospace applications, and other high-grade industrial equipment across the world. Maxon focuses strongly on innovation and offers some of the best units with excellent torque-to-size ratios.

3. Johnson Electric

Johnson Electric supplies brushed DCs for a wide range of household and automotive applications. They are known for their durability and consistent quality, along with extensive testing of each unit before delivery.

4. Mabuchi Motor

Mabuchi is a leading name in small brushed DCs. Mabuchi frequently supplies units for consumer electronics, automotive accessories, and toys. They are well known globally for their reliability, affordable solutions, and wide distributor network.

5. Portescap

Portescap offers specialized brushed DCs, particularly for medical and industrial applications. Some of their units are also used in automation systems. Portescap focuses on producing options that are precise, efficient, and compact in size, making them ideal for high-performance requirements.

6. Faulhaber

Faulhaber is known for manufacturing some of the most miniature and portable brushed DCs with high efficiency, speed, and torque. Their products are widely used in high-grade applications, including robotic, astronomical, and aerospace systems.

7. Allied Motion Technologies

Allied Motion provides a broad range of brushed and brushless DC solutions. They also offer customization options, especially for industrial and automotive applications. Units from Allied Motion are known for their reliable performance, quality construction, and responsive customer support.

Choose The Right Brushed DC Solutions – Connect With DMKE Today!

With DMKE, you can choose the perfect brushed direct current motor for your specific needs and applications without compromising on performance or quality. The experts at DMKE also offer customized motor solutions along with OEM and ODM services. You can also choose from our range of ready-made motor products if preferred.

Besuchen Sie unsere Website oder Kontaktieren Sie uns noch heute to discuss your requirements and get a unit made exactly the way you want.