BLDC Worm Gear Motor

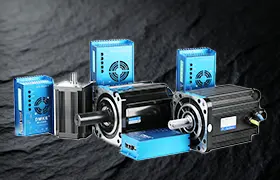

- DMKE

- Brushless DC Motor

- BLDC Worm Gear Motor

BLDC worm gear motors combine the high efficiency and precise control of a Brushless DC motor with the high torque, compact right-angle design, and inherent self-locking capability of a worm gearbox.

BLDC Worm Gear Motor

This BLDC worm gear motor combines a brushless DC electric motor with a robust worm gear system, delivering high torque and compact design ideal for tracked robots. The key feature of this electric motor worm gear configuration is its inherent self-locking capability, which safely prevents back-driving and is essential for lifting applications that require secure load positioning. It offers precise speed control and smooth, quiet operation, enhancing performance in demanding environments. The durability of the system ensures reliable service with minimal maintenance. These characteristics make it a superior choice for applications ranging from agile mobile platforms to safety-critical lifting equipment.

| BLDC Worm Gear Motor | |

| Rated power(W) | 10W to 10KW |

| Rated voltage(V) | DC 12V,24V,36V,48V,72V,96V,310V |

| Flange size range | RV25,RV30,RV40,RV50,RV63.RV75, RV90,RV105,RV110,RV130,RV150 |

| Rated torque range(N.m) | 0.5 to 1000N.m |

| Gear ratio: | 7.5,10,15,20,25,30,40,50,60,80,100 |

Precision in Motion:Where BLDC Worm Gear Motors Excel

Track-Driven Mobile Robots & AGVs

In rugged crawler robots and Automated Guided Vehicles (AGVs), BLDC worm gear motors deliver high torque at low speeds, enabling stable movement over uneven terrain or steep inclines . Their compact design integrates seamlessly into tight spaces, while the worm gear’s self-locking property prevents backdriving, ensuring stability when halted mid-task .

Lifting Equipment & Elevation Systems

For height-adjustable workstations, electric drying racks, or warehouse lifts, these motors provide safe, controlled lifting. The self-locking mechanism inherently secures loads in place without external brakes, eliminating the risk of accidental descent and enhancing operational safety .

Why are they the preferred choice for demanding applications?

High Torque in Compact Form

The worm gear mechanism multiplies torque while maintaining a small footprint, ideal for space-constrained mobile robots or embedded systems .

Self-Locking for Safety

The worm gear’s innate inability to be backdriven provides a fail-safe hold, critical for lifting devices or vertical actuators .

Quiet and Efficient Operation

With no brushes to cause friction, BLDC motors run quietly and efficiently, reducing noise pollution in workplaces and minimizing energy waste .

Precise Control and Long Lifespan

Electronic commutation enables exact speed and position control, while the brushless design eliminates wear from physical contacts, extending service life and reducing maintenance .

Why DMKE

In-House Production with 150+ Workforce

Wide Power Spectrum: 5W to 25KW Brushless DC Motors

16+ Years of Motor Industry Expertise & Application Knowledge

Integrated Motor & Drive Systems for Seamless Responsibility

Free Expert Pre-Sales Engineering & Selection Support

ISO9001, CE & RoHS Certified Quality Assurance

40+ Patents & 20+ R&D Engineers for Custom Solutions

Professional & Responsive After-Sales Technical Support