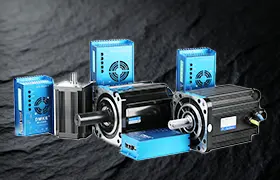

BLDC Gear Motor

- DMKE

- Brushless DC Motor

- BLDC Gear Motor

BLDC gear motors combine the high efficiency, smooth operation, and long lifespan of a Brushless DC motor with the high torque and reduced output speed of a gearbox.

About BLDC Gear Motor

The brushless motor gear system in a BLDC (Brushless DC) Gear Motor offers several advantageous characteristics for agricultural machinery, such as seeders. These motors are recognized for their high torque output, which is essential for driving the seeding mechanism consistently, even in tough soil conditions. Their high efficiency helps in reducing energy consumption, which is particularly beneficial for battery-operated equipment in vast fields. Furthermore, the durable construction often accompanied by IP54 or IP65 protection ratings, ensures reliable operation by shielding the motor from dust, moisture, and other environmental contaminants commonly encountered in farming .

| BLDC Gear Motor | ||||

| Rated power(W) | 10W to 750W | |||

| Rated voltage(V) | DC 12V,24V,36V,48V,310V | |||

| Flange size for gearbox(mm) | 60 | 80 | 90 | 104 |

| Max rated torque(N.m) | 3 | 8 | 20 | 40 |

| Gear ratio: | 3,5,7.5,10,12.5,15,18,20,25,30,36, | |||

| 40,50,60,75,90,100,120,150,180,200,300 | ||||

The Unseen Force Cultivating Tomorrow's Farms: BLDC Gear Motors

Seeders and Planters

BLDC gear motors drive precise seed placement with exceptional accuracy . They deliver consistent spacing and depth control, ensuring optimal germination rates while reducing seed waste—critical for both traditional fields and high-value crops .

By combining brute strength with intelligent control, BLDC gear motors are more than just components—they are vital partners in advancing precision farming. From boosting yield-per-acre to conserving resources, they help cultivate a future where technology and tradition grow hand in hand.

The Unmatched Advantages of BLDC Gear Motor Technology

Exceptional Reliability & Longevity

With no brushes to wear out and hardened steel gears, these motors withstand harsh environments (e.g., dust, moisture) and offer up to 25,000 hours of service life . This reduces downtime during critical planting or harvest windows .

High Torque in Compact Size

The integrated gearbox multiplies torque while maintaining a small footprint . This enables machinery to handle heavy loads—like fertilizer hoppers or harvesting arms—without bulky designs.

Precise Control and Energy Efficiency

BLDC technology delivers exact speed and position control, while electronic commutation minimizes power loss . This ensures accurate operations and extends battery life in electric or robotic equipment .

Low Maintenance and Overload Protection

Sealed gearboxes resist debris, and built-in safety mechanisms prevent gear damage during jams . This cuts maintenance costs and enhances machine longevity in unpredictable terrain.

Why DMKE

In-House Production with 150+ Workforce

Wide Power Spectrum: 5W to 25KW Brushless DC Motors

16+ Years of Motor Industry Expertise & Application Knowledge

Integrated Motor & Drive Systems for Seamless Responsibility

Free Expert Pre-Sales Engineering & Selection Support

ISO9001, CE & RoHS Certified Quality Assurance

40+ Patents & 20+ R&D Engineers for Custom Solutions

Professional & Responsive After-Sales Technical Support