In 2024, the market size of brushless DC motors (or BLDC) was $13 billion. And with a projected CAGR (annual growth rate) of 8.1%, the industry is on track to hit $20.68 billion in 2030.

Numbers like that don’t grow just because technology will get better. They grow because companies like manufacturers and OEMs are actively making a shift in their motor strategy.

Traditional motors have served industries for decades but modern factories are demanding something that’s more than ‘good enough’. Energy regulations are getting stricter, customers demand quick and silent operations, industrial buyers want 24/7 reliability, engineers need more precision, and lastly, the procurement teams are under pressure to reduce lifecycle costs.

That is exactly where BLDC motors are winning. They offer numerous advantages that solve the problems of today. In this guide, we’ll delve into five advantages that BLDC motors provide over traditional motors. We want to be honest so you’ll also get to read about the disadvantages and the practical considerations for you or your team that wants to get a brushless motor over a traditional one.

What Corporate Buyers Should Keep in Mind Before Comparing Motor Types

Selecting a motor is not merely an engineering task. It is largely concerned with the financial outcomes and long-term service costs. So before we compare the BLDC motors with traditional motors, buyers should understand the business factors that actually drive this ROI.

Buying experience involves more than engineering requirements

When making a decision to purchase something for your business, there are usually two types of factors to consider: technical and non-technical. For a technical product like a motor, many decision makers put an emphasis on engineering factors only. In reality, both factors must be considered.

In non-technical ones, the cost is an important non-technical factor. Similarly, lead times and availability of customization if you are looking for something specific in a particular span of time.

Motor influence cost and user experience

A motor has a significant influence on how much energy a product consumers and how often it requires services. These factors can shape the overall cost and performance.

When a motor fails or performs horribly, the customer does not blame the motor. Instead, they blame the brand that’s housing the product. As a manufacturer, this can ruin your reputation and destroy the loyalty of your customers.

Typical problems buyers face with traditional motors

Now let’s discuss the problem that you might face if you buy a traditional motor. This will help you set a ground for comparison when we discuss the advantages of brushless motors.

First of all, there’s the problem of wearing out. Because of this, there’s always a need for replacing the parts of the traditional motor. Heat builds up more quickly and shortens the life of nearby components.

Noise levels also rise over time if you don’t replace the degraded parts. All of these issues add up and create hidden expenses that accumulate over time.

Now that you know the problems of traditional motors, let’s see how the brushless counterparts can help solve them.

Advantage #1: Lower Operating Cost via Higher Energy Efficiency

Energy efficiency is usually mentioned first for BLDC motors. For decision makers, this is not just a perk for engineering operations. It is a major financial advantage that compounds over time.

Why BLDC motors consume less power

Why lower operating cost due to higher energy efficiency will be understood when you understand why BLDC motors consume less power than traditional ones.

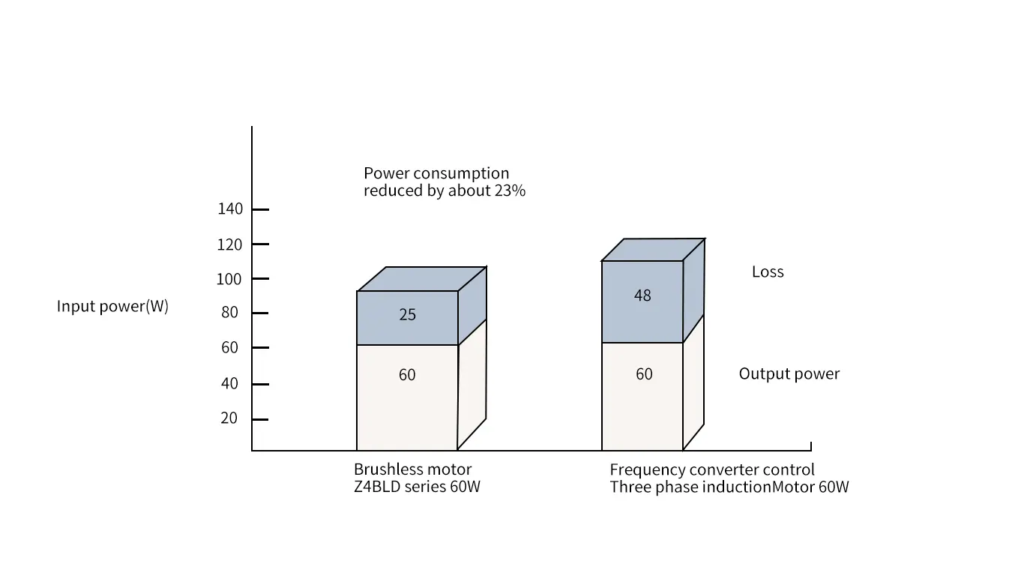

Brushless DC motors work by converting a large portion of electrical input into mechanical output. There is no brush that wastes energy as friction or heat.

Moreover, the electronic control keeps the motor running only as fast as needed. This results in smoother power delivery and thus, has less spikes that create unnecessary consumption. In practical terms, the motor uses less energy compared to a traditional brushed machine.

How energy efficiency reduces operation costs

Less energy directly reduces electricity bills, especially for equipment that runs continuously.

For commercial and industrial products, even a small reduction adds up across hundreds or thousands of units in the field.

Lower power consumption also reduces heat buildup inside the product. This way, the components stay protected and service life of the entire system is extended. This means, no extra costs of replacements.

Efficiency as a market advantage in regulated industries

Sectors like HVAC and home appliances are facing strict efficiency rules. Therefore, if a product fails to meet targeted energy levels, it loses access to key market consumers.

BLDC helps companies meet these standards without redesigning the rest of their product. High efficiency ratings improve the labeling of their product. A better rating holds the power to shift a product into a higher value category.

Energy savings may outweigh the initial cost

BLDC motors often cost more upfront. However, the payback period is usually shorter than what many buyers expect.

The difference in operational cost becomes visible within months for high-use equipment. For medium-duty applications, savings may be able to cover the initial cost within a year or two.

Once the payback period is reached, the motor continues to deliver reduced operating cost as long as it works. This can last significantly longer than a traditional motor.

Advantage #2: Longer Lifespan

When you are purchasing anything, price is an important factor. However, the upfront cost must never be the only thing that you should consider. In fact, the real financial impact shows up after the product is in the field.

A motor that lasts longer and requires fewer interventions reshapes a lot of things. BLDC delivers a clear advantage as its design removes the common points of failure that traditional motors face

A different mechanical foundation

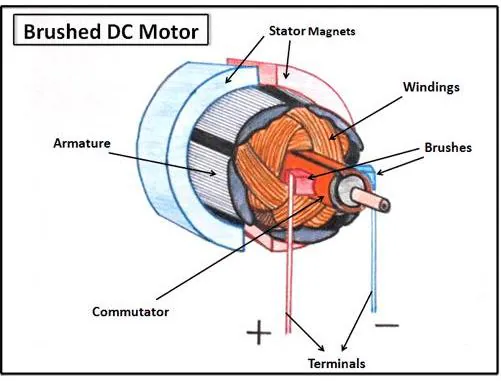

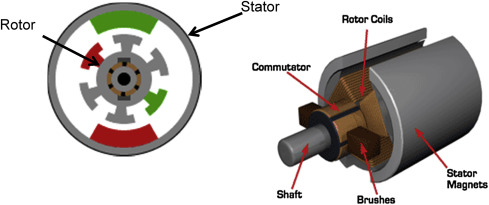

Traditional motors work when the brushes constantly make physical contact with the commutator. This creates a rotation. It works well but the contact surfaces degrade from friction. When it wears out, the motor loses power and stops eventually. The problem is unavoidable as the brushes are consumable parts.

BLDC, on the other hand, does not use brushes. The rotation is controlled through an electronic input. Therefore, there’s no internal part grinding away every second the motor runs. This change alone increases the expected lifespan because the failure mechanism has been removed.

Lower maintenance burden across the product’s lifetime

Because of constant wear, routine maintenance cost becomes a huge burden for both: manufacturers and users. Maintenance teams have to constantly check the brush conditions and replace worn components of brushed motors.

BLDC motors eliminate most of these tasks. With no brushes, there’s nothing to replace or clean. Heat generation is also lower so nearby components also stay healthy for a longer time.

A stronger fit for sealed or inaccessible installations

Some products hide their motors inside sealed enclosures or hard to reach locations. This includes the ceiling mounted air systems or compact medical tools.

When a motor in these setups needs service, the repair cost becomes huge as the unit must be opened in a different way. That’s why traditional motors add risk here.

What this advantage means for buyers

For decision makers, the value of longer lifespan and reduced maintenance is straightforward. Products become more dependable. This way, service teams stay focused on high priority issues rather than repetitive motor replacements.

If you are thinking about purchasing a BLCD motor for your company, it’s worth checking different variations of BLDC that DMKE offers.

Advantage #3: Precision and Control

Today, buyers want operations that are smooth and motions that are predictable. BLDC motors offer a level of control that traditional motors can’t match.

Controlled movement

Every movement that is produced by a BLDC motor is managed through an electronic controller. This controller reads position and speed signals + it adjusts the current flow in real time. This creates a stable and accurate rotation pattern. Moreover, it can start + stop + adjust speed with far less deviation.

Consistent torque

Equipment that works with varying loads needs reliable torque output. BLDC motors not only supply consistent torque, it does so at a wide speed range. The motor also keeps its performance even during rapid changes in operating conditions.

Advantage #4: High Power Density and Compact Form Factors

Companies that are building modern equipment often face the problem of strict space and weight limitations. Materials cost more and consumer expectation leans more towards the smaller products. Moreover, many sectors are now competing on portability and design.

BLDC motors support these goals as they generate more power from a smaller footprint. This benefit shapes everything from manufacturing costs to positioning within your market.

Greater output from a smaller volume

A BLDC motor produces strong rotational force from a compact package. The internal layout allows the motor to provide higher efficiency without needing large windings or bulky supporting structures.

On the other hand, the traditional counterparts usually need more physical space to achieve similar performance. Therefore, the space efficiency of BLDC becomes an important advantage when the manufacturer wants to shrink a product or add features but keep the size unchanged.

Better design freedom for new product lines

The engineering team gains extra flexibility when the motor takes up less room. They can easily add the features that were previously impossible due to limited space.

This allows the brand to release models with cleaner layouts and better proportions + the smaller motor footprint opens the door to innovations like compact airflow systems and foldable mechanisms.

Less usage of material and simpler assembly

When a product uses a smaller motor, the surrounding structure can also become light. Insulators and mounting plates can shrink or move to simpler shapes. This ends up reducing the cost of material and shortens the assembly time. In high-volume productions, these savings become meaningful.

Lower shipping costs

Shipping weight affects the overall spending on logistics. When a motor is light in weight, it automatically lowers the shipment fees for inbound components. This advantage becomes particularly important for companies that are handling large loads or international shipments.

Advantage #5: Lower Noise

Noise and vibration influence purchasing decisions more than most companies expect. This ends up affecting the comfort of users and also restricts compliance with strict sound regulations. BLDC motors excel in environments where stable and quiet operation becomes essential.

Better customer experience

Products that operate without noise feel more trustworthy. Whether it is a home appliance, a mobility device, or a piece of medical equipment, the sound level sets the tone for how the user perceives its value.

A BLDC motor has a smoother acoustic profile as there are no brushes rubbing constantly against a commutator. This absence of contact removes a major source of noise that the traditional motors can not avoid.

Reduced vibration

Vibration does not stay isolated in the motor’s components. It spreads through the entire structure and may cause many troubles (loosens fasteners, for example).

A BLDC motor operates with a balanced electromagnetic drive that reduces the shaking at all speeds. Companies can benefit from this stability as it lowers the risk of internal damage and preserves the integrity of surrounding components. This way, products last longer.

Cleaner operation

Brushed motors shed carbon particles over time which creates internal contamination. It can reach sensors and other sensitive parts.

BLDC motors eliminate this issue and the result is a cleaner interior. This becomes important in laboratories and medical devices where clear operation is highly critical.

Drawbacks of BLDC Motors

So far, we have only discussed the pros of BLDC. However, it’s definitely not a hero that is perfect from every angle as it comes with character flaws too.

A BLDC motor usually costs more at the purchasing stage. If budgeting is your priority, this might become a problem for you initially. However, if you consider the long-term savings, this con shouldn’t feel like a burden. Lower energy consumption and long service life usually cover that additional cost.

However, the second con is more serious. Transitioning from brushed technologies requires training. Engineering must be able to perform controlled programming and understand various other things to make the BLDC work as required. This could cause a temporary slowdown in the adoption phase but once the team is trained, it gets easier.

Industry-Specific Purchase Scenarios

Every industry has different machinery requirements. Therefore, all of them evaluate motors differently. For example, the priorities of an appliance brand has little in common with those of a medical device manufacturer.

That’s why, we have laid down some scenarios to explain how decision makers from different sectors can assess BLDC motors.

Appliance manufacturing

The efficiency labels matter a lot while selling appliance products. A refrigerator, washing machine, or air purifier with stronger energy ratings usually stands out in the retail environments.

BLDC motors help the manufacturers in meeting these targets as they reduce electrical losses during daily operation. Buyers in this segment also look for better durability to limit warranty returns.

Quiet operation also matters since noise levels are visible on appliance labels in some regions. BLDC motors supper these goals by providing the benefits that were enlisted earlier.

Industrial automation

Factories rely on equipment that can not fail during production cycles. Automation buyers often pay close attention to uptime percentages and total cost of equipment ownership.

A BLDC motor provides consistent torque delivery + stable thermal behavior. This helps in maintaining performance across the long shifts.

Electric vehicles and mobility devices

Energy efficiency and weight drives most decisions in this sector. A battery powered product gains considerable range when the motor converts stored energy into mechanical output with minimal waste.

BLDC motors meet this requirement by drawing less current for the same torque output. A lighter motor also improves stability.

Medical equipment

Hospitals, labs, and clinics value these three things: stability, hygiene, and quiet performance. A motor that produces dust or vibration creates problems for sensitive instruments.

BLDM motors avoid these issues as they have no brushes that shed particles + they offer smooth operations.

Ventilation systems

Energy regulations are tightening in all sectors, particularly in heating and ventilation. Manufacturers must comply with standards that demand lower power consumption across all operating modes.

BLDC helps achieve these targets as they operate efficiently at variable speeds. HVAC (Heating, Ventilation, and Air Conditioning) products also run for many hours each day so electricity savings accumulate quickly. Sustainability teams value these benefits a lot.

What buyers can learn from these scenarios

Each industry scenario that we laid out approaches motor selection from a different angle. However, the common pattern is that a BLDC motor aligns with long term value goals rather than short term cost metrics.

Selecting the Right BLDC Motor Supplier

Not all suppliers are equal and a strong partner can streamline integration and provide consistent quality while a weak supplier can introduce delays and cause operational headaches.

Evaluate technical expertise and support

A supplier with deep BLDC experience can provide more than motors. They guide and help tune the components. This reduces the burden on your in-house engineering team. If this sounds like a benefit for you, consider engaging with a knowledgeable partner like DMKE.

Check product range and customization capabilities

Not every BLDC motor is suitable for every application. Suppliers that offer a broad portfolio allow manufacturers to match motor performance to their requirements without compromise. DMKE offers various forms of BLDC like simple BLDC, gear motor, planetary gear motor, micro motor, and controller.

Conclusion

BLDC motors are no longer a niche technology. Their advantages are largely improving the performance of products and lowering the costs of operations around the world.

As a decision maker, these benefits mean stronger ROI and the ability to differentiate products in competitive markets. While there are high upfront costs, the long term advantages typically outweigh the initial investment.

For organizations that are evaluating the BLDC solutions, DMKE offers a wide range of high quality motors that are designed to meet diverse industry requirements. Explore DMKE’s offerings to find motors that align with your product goals.