If you have ever experienced buying a brushless motor, you know how hard it is. There are several, almost identical, options with crazy price differences, and the data sheets make no sense.

As a buyer, you naturally struggle with understanding what makes some options so cheap. Is a pricy option worth the investment? Would I get after-sales support and long-term value from a motor that’s priced in mid-range?

Our guide is here to clarify all such confusions you have. Below, we’ll break down the right way to evaluate a brushless motor’s value, how to understand the pricing, and how to evaluate a motor for its value for money when investing. So, read on:

Why Is Value Far More Important Than Price?

Making a good investment in any kind of motor is not only about the price. Rather, the real value of your purchase comes from how well the machine performs, whether or not it is low-maintenance, and how efficient it is in terms of output and precision. In short, you need to evaluate a product for its value and not just its price.

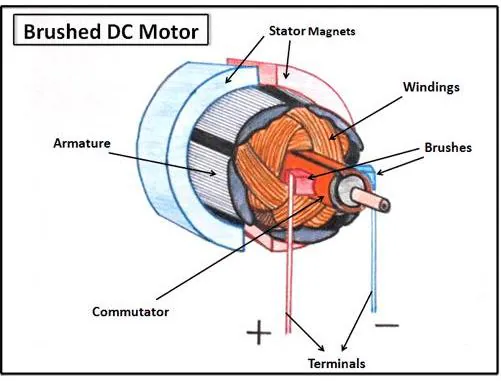

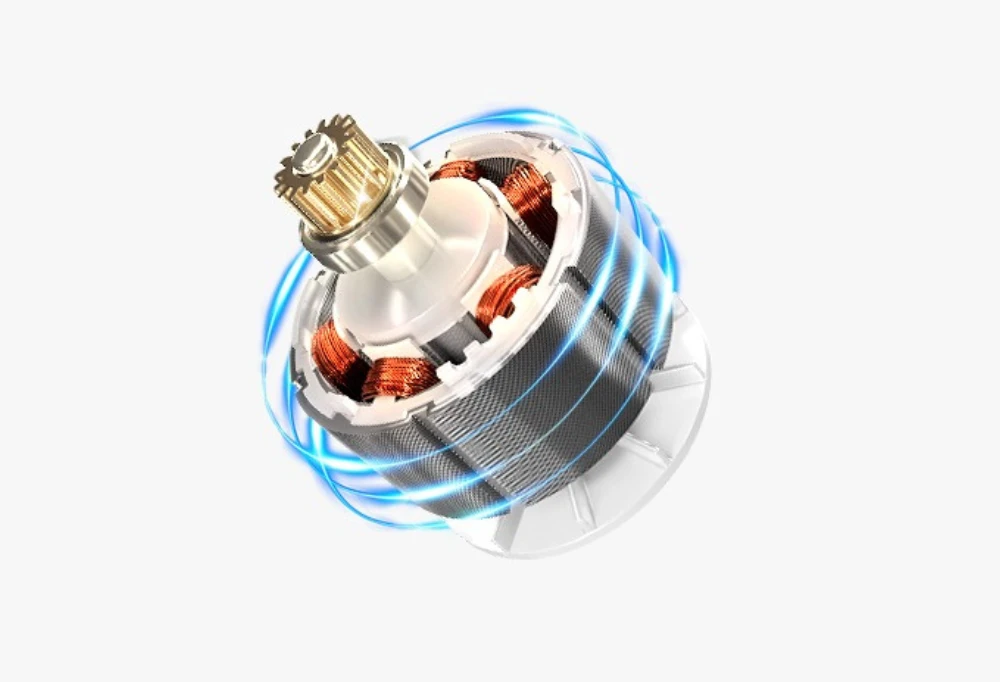

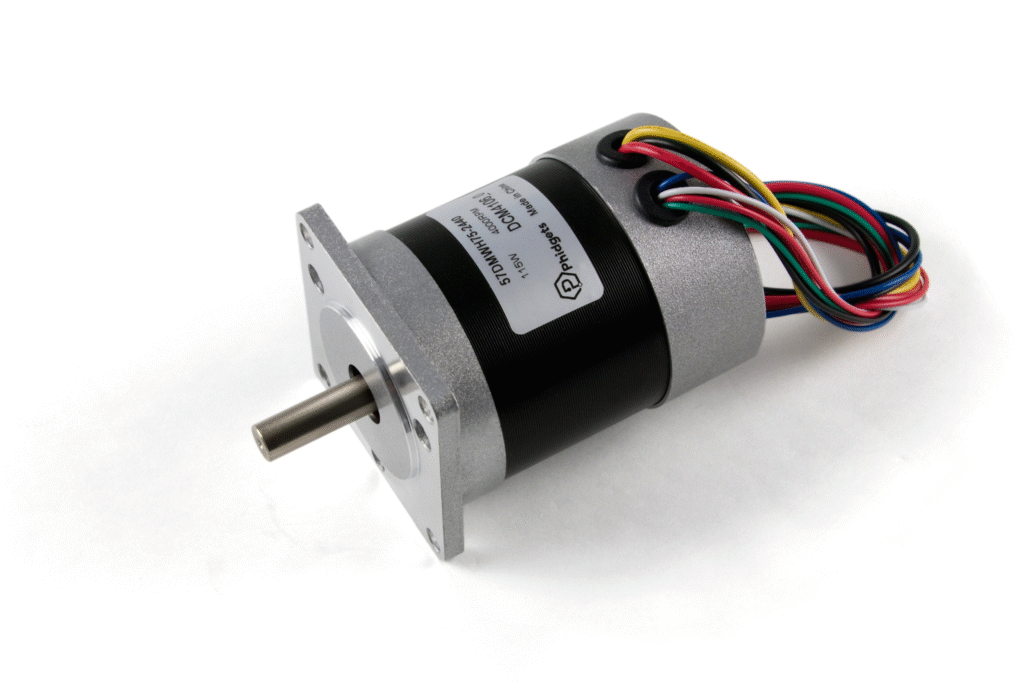

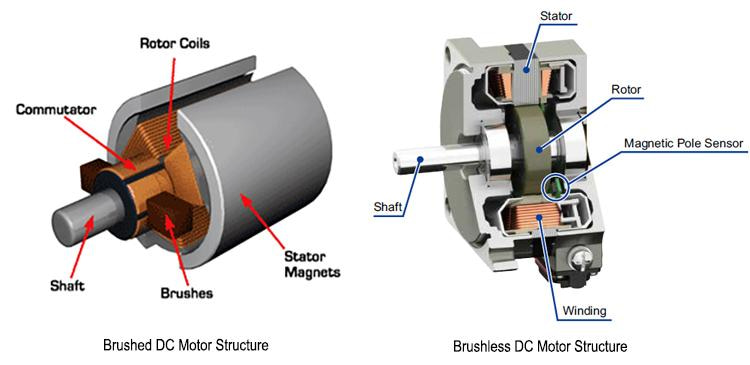

A brushless motor runs electronically, which means there are no sparks, no resistance, no brushes, and hence, definitely less downtime. This means they come with lower operational costs and smooth performance for longer durations. You need to see if your expensive purchase can fulfill these criteria.

Another thing to look at while assessing these devices for their worthiness is whether they offer consistent torque and high energy efficiency. If you get a cheap motor that doesn’t ensure consistency, it is not worth anything.

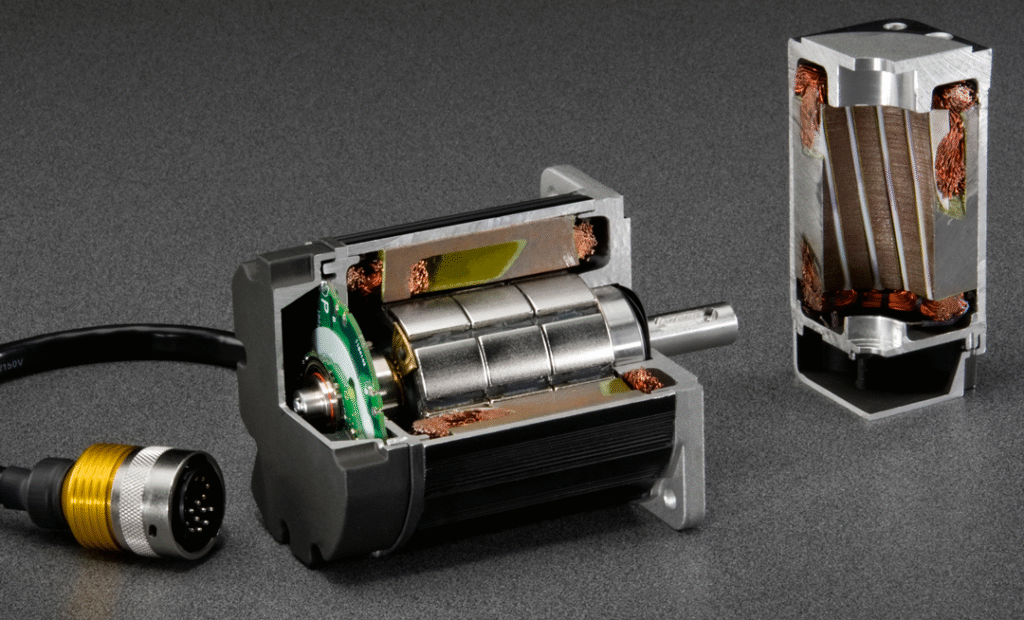

The durability of a brushless motor also defines its long-term value. With high-quality copper windings, perfect stators, and precision engineering, there is reduced energy loss and heat production. This makes spending on these devices a justifiable decision

In short, it is ok to pay a little more if it brings value in the long run. In fact, it can be a smart investment that protects your workflow and keeps everything on track with minimal stress on you and your budget.

Factors That Affect Brushless Motor Prices

Imagine you are comparing options to buy a good brushless motor. It is very common to come across motors that appear identical in terms of specifications but have very different prices. In such a case, it’s normal to wonder what exactly makes one option cheaper than the other.

The truth is: all reliable manufacturers price their products by balancing their precision, material quality, and the purpose for which it is made.

Below are some of the major factors that affect the cost of a brushless motor. Many of these factors may not be immediately apparent when you first look at different options. However, once you start using them regularly, you’ll begin to feel the difference.

1. Power and Torque Range

The power output of any mechanical device or system is usually the most significant factor that determines its price. It’s completely understandable why a compact brushless device meant for small appliances will cost less than a high-power one used in an industrial setup.

However, it’s also important to understand that the relationship between price and power output is not as simple as a straight line. Doubling the power output does not directly double the price.

A motor that performs better comes with higher wattage, and higher wattage requires intricate wiring techniques, stronger magnets, and advanced heat management. All these factors naturally add to the cost while enhancing the device’s performance and stability.

2. Design and Customization

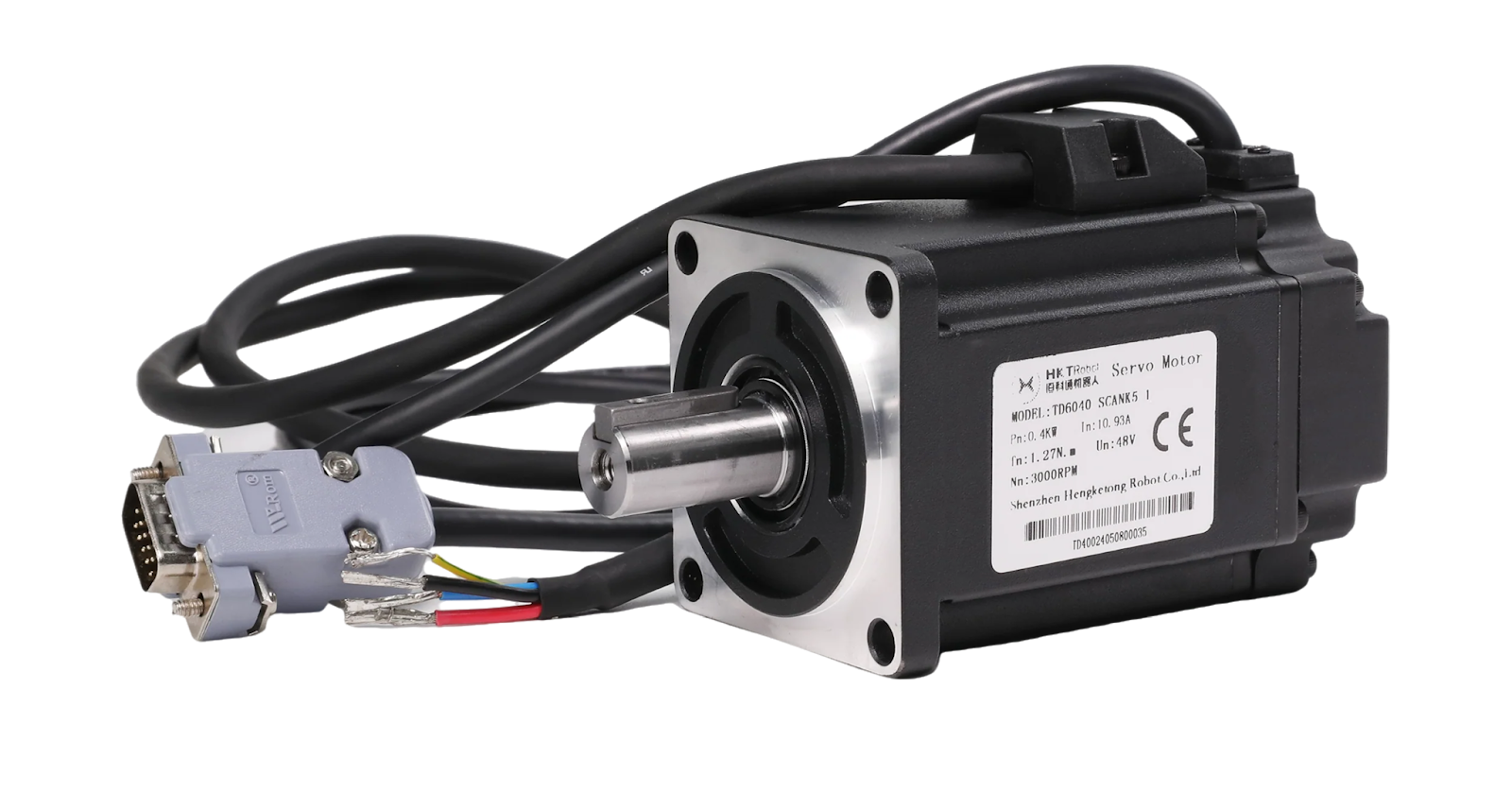

If you invest in mass-produced, ready-to-buy models, they are definitely cheaper than those made on demand. If you’re looking for specific torque curves, unique mountings, customized sizes or dimensions, or specialized sensors and feedback systems, then be ready to pay more.

Any customization to the mechanical or physical aspects of a device can affect its price. However, it’s important to note that a well-thought-out customized motor, no matter how expensive, often saves you a lot of money in the long run.

This is because such custom solutions are designed to perform exactly according to your specific needs, saving you from mechanical mismatches or the need to add extra components during installation.

3. Controller Type

For any motor, the controller is the main determinant of its behavior and output. There are many advanced motor controllers available. These offer features like field-oriented control, real-time feedback on speed and torque optimization, and improved precision. It’s obvious that a controller with all these features will come with a higher price tag.

Depending on the type of controller and driver you choose, the overall system can range from extremely affordable to quite expensive. At DMKE, we offer motor and driver bundles that pair ideal systems together at a reliable value.

4. Quality of Materials Used During Manufacture

The physical details of any brushless device might not seem very significant at first glance, but they can always be felt in the performance. Take, for example, the magnet grade, winding precision, and bearing quality. All these factors significantly influence the motor’s overall efficiency, durability, and stability. In the same way, these factors will add to the cost.

For example, if you demand your device to be made with high-grade neodymium magnets, you need to be ready to pay more. At DMKE, we ensure to maintain such standards in all our offerings. We’ve ISO9001-certified products that undergo proper testing prior to release. This makes all our electric motors deliver exactly what we promise.

5. Application and Environment

This one is again an obvious factor. If you want your device to work in harsh environments, it must have high-grade build and mechanical parts. Sellers who use such quality components naturally invest more resources in the manufacturing process. This ultimately adds to the selling price.

Brushless motors used in underwater devices, AGVs, and other medical equipment are made under the highest quality standards. This ensures a seamless output while also adding to the motor’s longevity. As a result, these motors come with a high price tag that is worth the investment.

6. Safety, Compliance, and Certifications

When purchasing any mechanical device, expensive or not, you should always ask for compliance and quality certifications. Certificates like the EMC, LVD, and RoHS are extremely important for any brushless motor. These certifications clearly prove the device’s ability to meet quality standards and perform well.

Anything that comes with such certifications is naturally expensive compared to one that has no quality proofs. Novice buyers often ignore the importance of these certifications and get lured by low price tags. As a result, they end with high-maintenance motors that don’t even last a year.

The truth is, if you’ve to pay a bit more than your budget for anything that comes with proper quality proofs, it’s worth it!

In short, a brushless motor’s price isn’t just a reflection of its quality. It is rather a manifold calculation of its longevity, suitability, ease of maintenance, and more. A slightly expensive option might leave a dent in your pocket at the time of purchase. However, it comes with long-term savings and an unmatched peace of mind that cheaper options can’t provide.

Average Brushless Motor Price Range by Type

As we have discussed in detail, the pricing of any brushless motor is defined by a range of factors. However, it is also important to understand that not every pricey item is truly expensive. Similarly, not every cheap one is worth buying.

Below is a generalized idea to help you understand what to expect when comparing the performance levels and pricing of any device.

| Motor Category | Power Range | Common Applications | Estimated Price Range (USD) |

| Miniature BLDC | 5W – 100W | Small appliances, automatic door systems, and ventilation fans | $10 – $50 |

| Mid-Power Brushless | 100W – 1KW | Robotics, conveyors, small machinery, AGVs | $50 – $200 |

| High-Power BLDC | 1KW – 10KW | Industrial automation, electric vehicles, production lines | $200 – $800 |

| High-Performance / Custom Systems | 10KW – 20KW+ | Medical, CNC, defense-grade automation, underwater, or special-purpose | $800 – $1500+ |

The prices in the above table only represent typical factory-direct rates. Sometimes, you can also get bulk discounts, or you might have to pay extra for customization.

In most cases, prices can drop when you pair the motor with the right driver or controller bundle. This is one of the major advantages of sourcing directly through manufacturers like DMKE rather than buying from distributors.

Another factor that affects cost is the brand itself. Some brands charge more because they have established fame in the motor industry. Such brands will be pricing their products partly for the brand name. A standalone manufacturer might not charge much for branding, but in most cases, the products they offer are genuinely worth the investment.

When investing in a motor, you also need to consider whether or not you’ll need to pay for the integrations and installations of the device later on.

If you are a first-time buyer, it’s important to know that a reliable supplier won’t just sell you one device; they’ll sell you continuity. For example, a $300 BLDC backed by a consistent supply, technical documentation, and after-sales support is far more valuable than an uncertified option with no guarantee.

How to Get the Best Value for Your Budget

Buying any brushless motor is not only about finding an item priced within your budget range. Rather, it is also about ensuring that every penny spent on that item gives measurable performance in return.

In terms of motors, the value for money comes from alignment, power, control, and the quality of the job done through them. Below are some of the best ways to make sure that whatever motor you are investing in brings genuine value for money.

1. Evaluating Total Ownership Costs And Not Just Purchase Prices

By now, you would be sure that the cost of a motor is not just the value of the item itself. Rather, it also includes the integration, installation, and maintenance costs for the future. When buying a low-cost motor, always consider factors like installation, controller compatibility, or early replacements.

In short, you need to evaluate what you’d be spending in the long run. Sometimes, a cheap option ends up having a negative impact.

2. Look for Motor + Controller Bundles

If you’re only buying a motor with no controller or driver, you’re making a huge mistake. When it’s time to install and run the device, you’d have to spend your time and money again to find the right controller.

Instead of worrying about these issues later, it is better to invest in ready-to-install bundles. Having the right controller for your device at hand won’t just save time but will also enhance the overall performance of the motor.

At DMKE, we provide proper motor-and-controller bundles to keep our buyers stress-free and give them devices that are ready to use right out of the box.

3. Consider After-sales Support and Customizations

The best value for money comes from investing in a supplier who cares about their clients and is ready to listen. Once you have installed a motorized device, you will need some post-installation support.

Sometimes you may need different-sized shafts, sometimes customizations, and sometimes after-sales service. Good factory support and a reliable supplier will provide you with all these things. This makes investing in their devices even more worthwhile in the long run.

4. Look At Quality Certifications As A Sign Of Value

One of the biggest mistakes a new buyer can make while investing in any motorized device is ignoring the certification and testing proofs. You only want to invest in suppliers who offer certifications like ISO 9001, ROHS, and EMC. These evidences ensure that your motor is built to last, providing durability and longevity in the long run..

5. Try Sourcing Directly from the Factory

Purchasing anything directly from its manufacturers eliminates unnecessary costs in the middle layers. In comparison, when you purchase from a distributor, they will sometimes charge you 20–30% more than the original price as part of their profit. Hence, it’s best to stay connected directly with the manufacturer.

Below is a table that helps you visualize common brushless motors for their applications and value for money.

| Motor Type | Power Range | Typical Applications | Feature Highlights | Value Tips |

| Mini BLDC | 5W – 100W | Small appliances, automatic doors, and fans | Compact size, low noise, moderate torque | Ideal for low-load applications; check controller compatibility |

| Mid-Power BLDC | 100W – 1KW | Robotics, AGVs, conveyors | Balanced torque, efficient, reliable | Opt for pre-tested motor-driver bundles for smooth integration |

| High-Power BLDC | 1KW – 10KW | Industrial automation, EVs, production lines | High torque, stable speed, robust bearings | Look for certifications and thermal management to maximize lifespan |

| Custom / High-Performance Servo | 10KW – 20KW+ | Medical devices, CNC, underwater, special-purpose | Tailored torque curves, integrated feedback, IP-rated | Invest in OEM/ODM solutions to minimize future modification costs |

Why Buy from DMKE And Other Reliable Manufacturers

Whenever you’re looking for a reliable motor supplier, we suggest you focus on qualities like strong research and development background, quality control, after-sales support, and the ability to offer customization. A supplier that meets these standards is the one you can blindly trust in most cases.

When you’re evaluating and inquiring about any item’s price, asking about these quality checks helps you better evaluate your decisions. Take DMKE as an example, we have been practicing all these standards to satisfy our clients to the best of our ability.

Below are some of our specific practices that set us apart from other motor suppliers:

- 16 years of experience

- Products tested and verified for ISO9001 certification

- After-sales support and service

- A dedicated R&D and testing team

- Pre-testing bundles

- Post-sales technical support

And many more.

In short, when it comes to motorized devices, purchasing a good and reliable item that brings value for money often depends on the manufacturer. Investing in items from reliable manufacturers is far more important than one might think.

Common Mistakes To Avoid

It is common for even the most experienced engineers and procurers to make mistakes when investing in a device with layers of technicalities. Below are some of the common errors that you can easily avoid when choosing a brushless motor for your projects.

- Focusing only on the base price is a huge mistake. Consider a motor as a long-term investment and evaluate all the possible costs associated with its installation and usage.

- Never overlook controller compatibility issues that you might face later on. Instead of waiting to find the right driver afterward, it is best to find an optimal option along with the motor.

- Never forget your exact need for a motor. Many end up buying extremely high-quality motors that are of no use for their projects.

- Never ignore environmental as well as project requirements when investing in any motorized device.

- Not considering long-term supplier or manufacturer support, after-sales services, and documentation is another mistake you would not want to make.

- Avoiding customization when it is needed is another mistake that leads people to buy useless devices that, no matter how well-made, are not suitable for their needs.

Conclusion: Invest Smartly in the Right Motor

At DMKE, we’re providing solutions for everyone, whether they are developing industrial systems or custom machinery. We keep our clients involved from the R&D phase to the production and finalization.

Offering reliable global delivery, we also ensure quick post-sales technical support, flexible OEM/ODM options, and motor and controller bundles to help you ensure efficiency and control.

Contact us to discuss your requirements today. We have been manufacturing flawless items for the past 16 years. Invest in our products get a combination of price and performance like never before.