If you are responsible for sourcing motors (like servo electric motors) for your machines, you already know how quickly things can go wrong. A motor that meets the specifications on paper can create delays and extra costs once the production begins. Maybe the torque does not match your system perfectly, or the feedback signals fail to deliver what the supplier promised. Sometimes a supplier promises fast delivery, only for lead times to stretch out completely.

These problems can become a technical annoyance. But most importantly, they can disrupt your production schedules, increase operational costs, and put pressure on your team to troubleshoot issues that could have been avoided if the right supplier was chosen.

However, supplier isn’t the only part of the decision formula. You also have to be aware of other factors like the increasingly complex global supply chains and the fact that the component quality can vary across regions.

All in all, sourcing the right servo electric motors can be challenging. To overcome this challenge, we wrote this complete procurement guide for OEMs. It will highlight common pitfalls, provide a list of suppliers you can choose, and show how to evaluate suppliers.

If you have ever felt the stress of trying to get the right motor delivered on time, this guide is written for you.

The OEM’s Challenge: What Goes Wrong in Servo Motor Procurement

One survey found that many OEM‑supplier relationships are under strain, with quality and communication being cited as major pain points.

At first, the supplier would show you a perfect product with the highest quality. This means that the specifications may match your system perfectly. However, when the motor arrives, even small differences can cause major issues. Torque fluctuations, encoder inconsistencies, and slight variations in speed can throw an entire assembly line off balance.

Even if the quality is consistent, unreliable delivery can disrupt your production. A motor that’s promised to be delivered in four weeks might take eight or more due to supply chain delays or communication gaps.

If you are in the business of high-volume production or just-in-time manufacturing, these delays can halt an entire line. For example, a packaging machine waiting for a servo motor may miss a shipping deadline, impacting contracts and customer trust.

Then, there are the hidden costs as the upfront price of a motor is rarely the full cost. Customization fees, special connectors, expedited shipping, and engineering time to adapt the motor can all add up. Many OEMs only discover these extra costs during assembly or testing, turning what looked like a cost-effective purchase into a budget strain.

Working with suppliers across different geographies adds another layer of complexity. Documentation standards, certifications, and after-sales support often vary. A vendor that delivers reliably in one market may struggle to provide the same quality or communication globally. For OEMs supplying international customers, this inconsistency can create compliance issues and complicate logistics.

Lastly, there’s the operational and emotional strain as sourcing the right servo electric motor can be mentally taxing for procurement teams. They have to constantly track shipments, verify quality, and troubleshoot unexpected issues. This puts pressure on both: engineering and operations which results in stress and slows down the decision making process.

How to Overcome These Challenges Using Strategy

The good news is you don’t have to accept this as the norm. By evaluating suppliers with the right criteria, insisting on consistent quality documentation, and mapping out the real lifecycle cost of the motor (not just the sticker price), you turn procurement from a reactive scramble into a strategic advantage.

With servo electric motors, the right approach means fewer surprises in your machine build, more reliability in the field, and better alignment between cost, quality and delivery. In the next few sections, you’ll learn more about the top suppliers and a guide to evaluate them.

Servo Electric Motors in OEM Integration: Key Technical Priorities

Before choosing a supplier, you need to consider the technicalities associated with choosing the right servo motor for OEM.

The first priority for OEM is accuracy and repeatability. Motors must deliver consistent performance in every cycle, ensuring your machine performs reliably across production batches. This precision cannot be compromised, especially in applications such as CNC machining, robotics, or automated assembly.

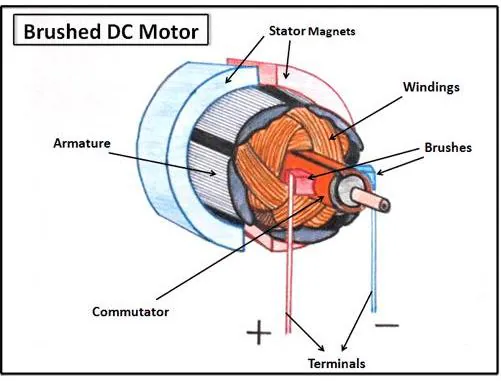

Next comes compatibility. Choosing the right type of motor ensures your design works as intended without costly modifications. Options include DC servo motors for compact spaces, servo planetary gear motors for high torque with minimal backlash, servo worm gear motors for right-angle or constrained layouts, and hub servo motors for direct-drive systems with simplified mechanics. Each type serves a purpose, but the key is fitting the motor seamlessly into your machine’s mechanical and electrical setup.

Finally, batch consistency is critical. One prototype working perfectly is not enough. Your supplier must deliver motors that perform the same way, every unit, every batch. Combining precision, integration, and reliable production is what makes servo electric motors a cornerstone of successful OEM machines.

But most important of all, you have to find the best supplier. In the next sections, we’ll go into this topic in more detail.

How OEMs Evaluate Servo Motor Suppliers

When your procurement team is on the hunt for servo electric motors, one of the most critical decisions is choosing the right supplier. A motor may look perfect on paper, but the supplier behind it often makes the difference between smooth production and repeated headaches. Below are key evaluation criteria and strategic checks to guide you toward a partner who delivers not just components, but dependable performance.

1. Reliability Before Everything Else

In automation, downtime costs more than almost anything else. That’s why reliability data is often the first thing engineers look at. It’s not enough for a supplier to say a motor lasts “long.” You want actual MTBF ((Mean Time Between Failures) numbers, long-term torque stability data, and performance records at different ambient temperatures. A motor that holds up under continuous duty in one region might fail in another if the quality control isn’t consistent.

Some OEM teams even ask for batch test reports or sample performance curves before placing large orders. The suppliers who can provide that level of transparency usually have tighter process management and better quality tracking.

2. Looking Beyond Unit Price

The cheapest servo motor rarely ends up being the least expensive in practice. What matters more is total cost across the product’s lifetime. Factors like calibration effort, setup time, or part replacement frequency all add up. A motor that costs a little more upfront but runs reliably for three years without adjustment often saves more than one that fails in eighteen months.

Experienced procurement teams compare cost per operational hour, not just invoice totals. That’s how they uncover real value.

3. Support That Feels Like Collaboration

Servo electric motors aren’t plug-and-play components. They need to be tuned, tested, and integrated with drives and controllers. Having a supplier who actually supports that process makes all the difference. The best ones respond quickly during prototyping, share tuning parameters, and help diagnose unexpected behavior during commissioning.

Many OEMs now rate suppliers by responsiveness, not just technical specs. It’s a sign of reliability that numbers can’t always show.

4. Documentation, Certifications and Traceability

For global OEMs, proper certification isn’t optional. Standards like ISO, CE, RoHS, UL, and CCC protect your export path and reduce approval delays with end clients. Still, it’s worth confirming that those certificates reflect real compliance, not just logo placement on the casing. A good supplier can explain how their QC system supports those standards in daily production.

5. Customization and Flexibility

Every OEM has a different mechanical layout or control setup. Sometimes a motor fits perfectly except for one small detail: the connector angle, encoder type, or shaft length. The ability to modify those elements without a new tooling process is what separates standard suppliers from partners.

Flexible manufacturers can make small design tweaks, adjust winding specs, or provide alternate feedback options without long lead times. That kind of adaptability saves redesign costs and speeds up production cycles.

Top Global Servo Motor Suppliers for OEM Procurement

Let’s take a look at the top four global servo motor suppliers. These are the best players of the league. However, we also encourage you to evaluate each supplier according to the criteria we mentioned in the previous section to decide which one meets your needs the best.

1. Oriental Motor

Oriental Motor has built a strong reputation for reliable servo electric motors. Their portfolio spans compact DC and AC servo motors, integrated drivers, and complete motion solutions. Their pricing is also competitive.

However, customization options are limited compared to some other suppliers. They also don’t have a lot of information about their product’s specifications.

2. Delta Electronics

Delta Electronics delivers servo electric motors with a strong emphasis on energy efficiency and industrial automation. They have global reach so they can provide support across Asia, Europe, and the Americas.

3. DMKE

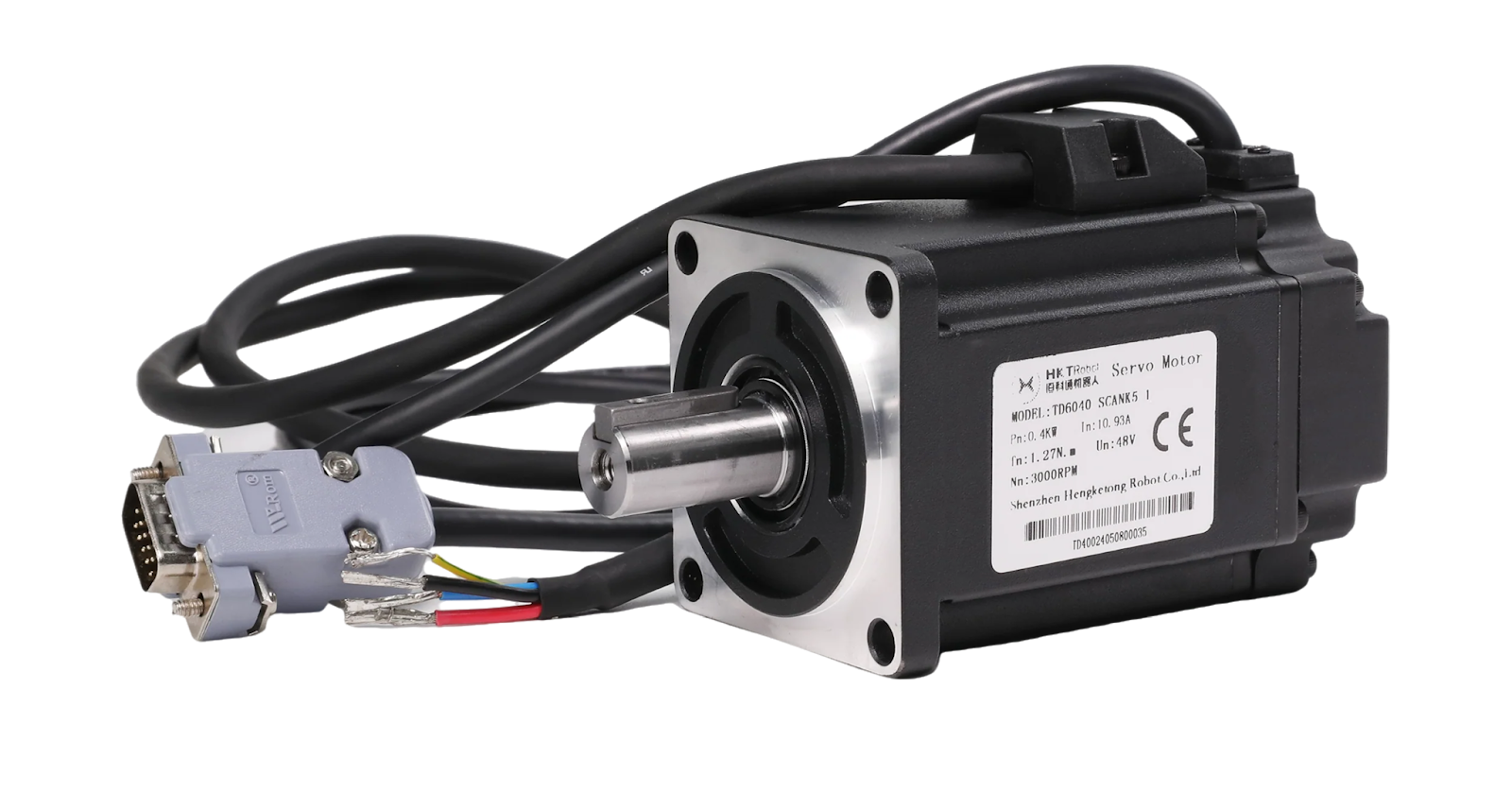

DMKE specializes in versatile servo electric motors tailored for OEM integration. Product range covers DC Servo Motors, Servo Planetary Gear Motors, Servo Worm Gear Motors, and Hub Servo Motors.

DMKE stands out for providing flexible OEM solutions with customization options, global shipping support, and reliable batch consistency. This makes DMKE ideal for projects where specific mechanical configurations are key.

4. Mitsubishi Electric

Mitsubishi Electric offers high-performance servo electric motors widely used in industrial automation and robotics. OEMs value their extensive global support network and standardized documentation.

Due to their strong brand name, prices might feel higher than specialized and niche servo motor suppliers.

5. Moog Inc.

Moog Inc. specializes in advanced servo electric motors. These motors are good for applications that need high torque and smooth performance under heavy loads.

OEMs working in aerospace, defense, and high-end industrial machinery often choose Moog for reliability and durability. Since they cater to big industries, their pricing can feel premium.

What Services do the Excellent Suppliers Provide

Purchasing servo motors is a lot more than adding a motor in a cart, checking out, and receiving at your address. Since it’s an important purchase for your business, an excellent supplier will provide services along with the product. Let’s take a look at some of these!

Cost Optimization in Servo Motor Procurement

A recent MarketsandMarkets report estimates that high-efficiency servo electric motors can lower total operational costs through better energy use and durability.

A reliable motor may cost slightly more upfront, but it reduces downtime, saves energy, and minimizes maintenance costs over the years.

Good suppliers understand that the lower price isn’t always the smartest choice. Therefore, they focus on cost throughout the lifecycle, not just at checkout. Excellent suppliers help OEMs achieve this balance by:

- Offering design recommendations to prevent over- or under-specification.

- Providing detailed technical data and test reports for confident selection.

- Maintaining stable pricing across production batches to protect margins.

This approach allows procurement teams to plan for long-term performance instead of focusing on immediate savings (that might end up costing more later).

Global Supply Chain Support

Even the best motor is useless if it arrives late. Supply chain reliability is one of the biggest value points a supplier can offer. The right partner helps you plan around your build schedule, not disrupt it.

They do this by maintaining:

- Transparent lead times with clear communication if delays arise

- Flexible minimum order quantities (MOQs) to match prototype and production stages

- Regional stock and global logistics coordination, ensuring quick fulfillment across markets

Here’s a quick table you can use on your next RFQ to assess supply chain readiness of the supplier for servo electric motors:

| Supply Chain Factor | Questions to Ask Supplier | Target Expectation |

| Lead Time | What is standard lead time, and what causes delays? | ≤ 8 weeks for standard models, variation ±10% |

| MOQ | What is the minimum order quantity? | Match your pilot + initial production quantity |

| Critical Sub-components | Are Hall sensors, magnets, encoders secured? | Supplier confirms stock/reserve or alternative path |

| Logistics | Are shipping lead times and customs delays mapped? | Shipping strategy and buffer inventory defined |

| Dual Sourcing/Backup Plan | Does the supplier have an alternate manufacturing line or partner? | Yes, alternate line or verified back-up partner |

| Quality and Traceability | Can you provide batch test data, material traceability? | Full documentation available on each batch |

| Export & Compliance Support | Do they support CE, UL, RoHS etc, with export paperwork? | Complete package available, no surprise fees |

Most good suppliers present this information on their website. However, if you can’t find something, you can always contact their team to learn more.

Quality Control and Testing Standards

Cost optimization doesn’t mean cutting corners. In fact, it depends on how tightly quality is managed. A great supplier ensures every motor that leaves the factory performs to spec, batch after batch.

They typically provide:

- Torque and speed test results for each batch.

- Material and winding traceability reports.

- Third-party certifications like CE, RoHS, and ISO 9001 compliance.

This level of documentation is what helps OEMs maintain confidence in their machines, especially when scaling production or meeting export regulations. When you can trace every bearing, magnet, or winding, quality becomes predictable. And that’s real cost control.

Engineering and Order Fulfillment Support

From prototyping to mass production, the right supplier supports you at every step. OEMs value partners who listen to their requirements and adapt quickly when designs evolve. That means:

- Early-stage collaboration to align motor specs with mechanical design.

- Quick parameter tuning and model recommendations for different use cases.

- Responsive after-sales and replacement support when production ramps up.

Suppliers who treat this as part of their process help reduce engineering workload and speed up development cycles. For example, in the image above, you can see the support DMKE offers throughout the order fulfillment process.

Partnering with a Trusted Servo Motor Manufacturer

Choosing a servo motor supplier isn’t about filling a parts list. It’s about finding a partner who understands how your machines work and helps you keep them running smoothly from design to delivery.

That’s where DMKE stands out. As a long-term manufacturer of servo electric motors, DMKE works closely with OEMs to fine-tune performance, balance budgets, and keep supply chains predictable. Their engineering team helps match torque, speed, and configuration early in the design stage so you avoid rework later.

DMKE’s lineup covers a full range of motion solutions:

- DC servo motor: for compact automation and precise control.

- Servo planetary gear motor: for high-torque, low-backlash applications.

- Servo worm gear motor: for reliable, quiet transmission in tight spaces.

- Hub servo motor: for direct-drive systems that need smooth, responsive motion.

If your machines depend on precision, partner with a team that builds it into every motor. Learn more by visiting DMKE’s website.

Conclusion

For OEMs, winning in today’s market is not about finding the cheapest parts. They have to build dependable partnerships that keep machines running smoothly and keep their production on track.

Smart procurement turns every challenge (related to cost, delivery, quality) into a long-term advantage when you work with suppliers who understand both engineering and business priorities.

That’s where DMKE adds real value. With years of experience in servo electric motors, the company helps OEMs balance precision with affordability. From custom configurations to stable lead times and consistent product quality, DMKE gives teams the confidence to plan production without second-guessing their supply chain.

If you’re ready to simplify your procurement process and secure reliable servo electric motor supply, visit DMKE to explore solutions for your next project or connect with our experts.