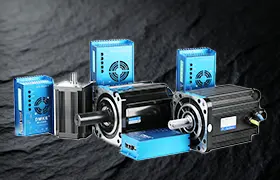

Servo planetary gear motor

- DMKE

- Brushless Servo Motor

- Servo planetary gear motor

Servo planetary gear motors combine high-precision servo control with the high torque and durability of a planetary gearbox, delivering exceptional performance for demanding automation applications.

About Servo planetary gear motor

Servo Planetary Gear Motors deliver unmatched precision and power for critical medical technology, from robotic surgery to diagnostic automation. Their compact, high-torque design with minimal backlash ensures exceptionally smooth and reliable motion, making them the trusted drive solution where accuracy directly impacts patient care and medical outcomes.

The Pulse of Precision-Servo Planetary Gear Motors

In mission-critical fields where failure is not an option, the muscle behind precise motion depends on a superior force. Servo Planetary Gear Motors have emerged as the robust, intelligent core delivering controlled movement in the devices that save lives and conquer the skies.

Diagnostic Imaging & Patient Tables

From positioning a patient in an MRI to aligning components in a CT scanner, Servo Planetary Gear Motors offer exceptional stability and control. They enable smooth, reliable, and vibration-free movement, which is crucial for patient comfort and achieving high-resolution diagnostic images.

Aerospace Actuation & Control

In flight surfaces and landing gear systems, power and reliability are paramount. Servo Planetary Gear Motors manage the immense loads required to move ailerons, rudders, and gears with unwavering precision. Their compact, robust design ensures dependable performance in the harsh environments of both commercial and military aircraft.

The Unmatched Advantages of Servo Planetary Gear Technology

Exceptional Torque Density & Robustness

The planetary gear design distributes load across multiple gears, achieving very high torque output from a compact and rigid package. This provides the muscle for surgical robots and aircraft actuators without sacrificing space or weight.

Precise Positioning & Low Backlash

Precision-engineered for minimal backlash, Servo Planetary Gear Motors enable highly accurate positional control and repeatability. This is fundamental for the delicate movements of surgical instruments and the exact positioning of satellite components.

High Rigidity & Torsional Stiffness

The system exhibits high resistance to dynamic loads and bending moments, maintaining alignment and precision under force. This ensures stability in robotic arms and consistent performance in flight control systems.

Compact Design & High Durability

The coaxial design offers an optimal power-to-size ratio, which is critical for integrating into portable medical devices and weight-sensitive aerospace vehicles. Built for longevity, they provide reliable operation over long lifetimes with minimal maintenance.

Why DMKE

In-House Production with 150+ Workforce

Wide Power Spectrum: 5W to 25KW Brushless DC Motors

16+ Years of Motor Industry Expertise & Application Knowledge

Integrated Motor & Drive Systems for Seamless Responsibility

Free Expert Pre-Sales Engineering & Selection Support

ISO9001, CE & RoHS Certified Quality Assurance

40+ Patents & 20+ R&D Engineers for Custom Solutions

Professional & Responsive After-Sales Technical Support