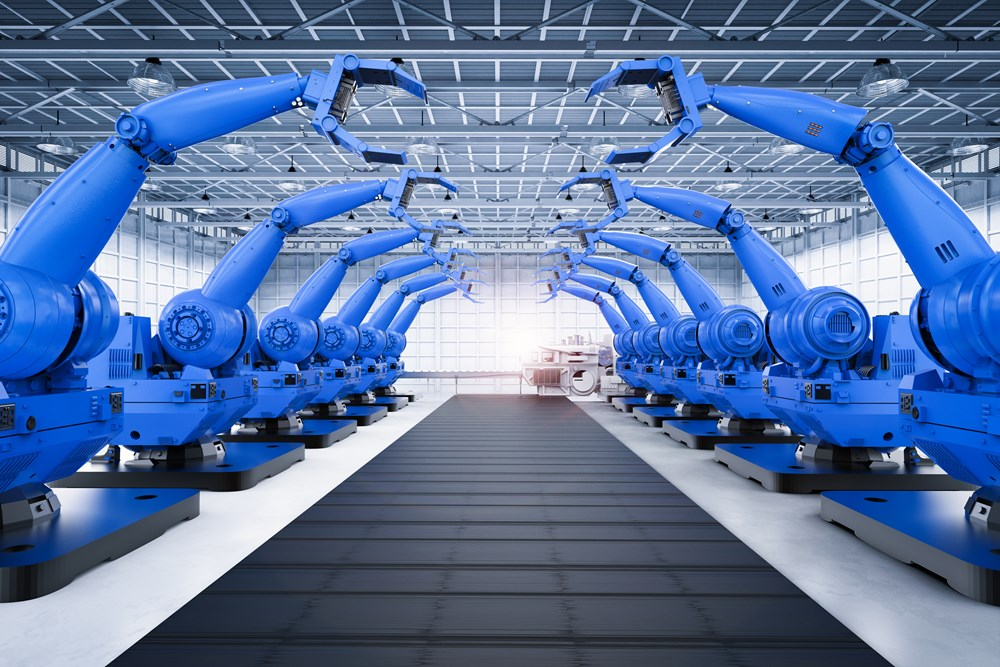

The production line was running perfectly at 10 AM. Boxes moved in sync, robots placed parts with precision, and everything was scheduled. Then, without warning, the conveyor stopped. A servo motor had failed.

The maintenance team jumped into action. They diagnosed the issue quickly, tracing it to a single servo component in the motion control system. But sourcing a replacement wasn’t so easy. The supplier quoted an eight-week lead time. Eight weeks of waiting. Eight weeks of missed shipments, idle labor, and frustrated clients.

For many manufacturers, this scenario feels all too familiar. One small actuator failure can cascade into costly downtime across an entire production system. According to a study by Siemens, unplanned downtime costs the manufacturing industry nearly $1.5 trillion each year, eating up about 11% of annual revenue of Fortune Global 500 companies.

Today’s industrial buyers face a new kind of challenge. It’s no longer just about choosing the right servo model or controller with advanced response technology. It’s about securing dependable servos that are available now, adaptable to different servo sizes, and backed by reliable partners who understand that every hour counts.

This is where a new approach to modern servos comes into focus. Built for speed, stability, and precision control, this strategy empowers manufacturers to respond fast. This is done without the risks of traditional customization or the drag of endless lead times.

Let’s explore how servo systems designed for immediate deployment are changing how industrial teams handle downtime, supply pressure, and operational performance.

The Procurement Crisis & the Pain Points

Understanding why traditional procurement methods fail is crucial for industrial buyers navigating modern servo systems.

Unstable Global Supply Chains and Extended Lead Times

Understanding why traditional procurement methods fail is crucial for industrial buyers navigating modern servo systems. Lead time delays and unstable supply chains create real operational risks, and the wrong strategy can cost months in production.

A primary cause is the scarcity of essential components like programmed microcontrollers, high-performance servo drivers, and precision actuators that make a servo motor controller function. Even if the shaft, gearbox, and mechanical parts of a servo are available, the electronics can stall production for months.

Furthermore, geopolitical risks and raw material shortages (copper, rare earth magnets for motors) add layers of unpredictability. This confluence of factors has stretched procurement cycles from the standard 8-12 weeks to an astounding 6-18 months in some specialized segments. This extended timeline makes accurate business forecasting virtually impossible.

The key takeaway for you is clear: your entire build schedule is now dictated by component availability, not by your internal market forecasts or engineering readiness. Strategic partnership is required to navigate this availability crisis.

The Customization Conundrum: Too Slow, Too Risky

The impulse to customize every accessory is a legacy habit that is now proving extremely costly. Seeking the perfect servo model or specialized controller often requires many months of prototyping, followed by long waits for custom actuators, servo shafts, or metal gear servo assemblies.

This cycle typically requires spending four to six months on initial prototyping, testing, and validation of the new design, only to discover that the unique magnet assembly or specialized micro-connector needed for this custom actuator has a 12-month component lead time.

This customization trap also introduces significant financial risk. High Non-Recurring Engineering (NRE) costs are sunk into designs that may become obsolete before they even reach mass production due to unforeseen regulatory changes or shifts in component availability.

Furthermore, relying on highly customized motion controlled and microcontroller components creates deep reliance on single-source suppliers, multiplying the systemic risk in a volatile market. If that single supplier struggles, your entire product line is halted.

The Opportunity Cost of Stagnation

Every idle day carries real financial consequences. Waiting for a micro servo, servomotor, or servo controller can mean lost production, underutilized labor, and missed revenue opportunities.

For OEMs, delays also affect automation projects where actuators, linear actuators, and rotary actuators are critical to replacing labor-intensive tasks. Each postponed deployment reduces torque output, slows rotation of mechanisms, and limits overall operational efficiency.

Industrial buyers must balance the power, speed, and torque requirements of servos with lead time realities. Slow customization and long procurement cycles are no longer acceptable. The key question is not simply which servo fits the technical specification, but which can be delivered reliably to maintain continuous operations.

Conventional Servos Procurement Pitfalls

A strategic shift requires not only understanding external market forces but also identifying and eliminating costly, time-consuming internal habits. This section highlights three critical mistakes that often derail even well-planned automation projects.

The Illusion of Perfection

One of the most common mistakes is demanding highly tailored servo motor solutions when a standardized servo model would suffice. Engineers may over-specify components like microcontrollers, custom servo shafts, or specialized metal gear servo assemblies in pursuit of marginal gains.

While theoretically improving torque, speed, or rotation control, this approach introduces delays in the servo driver supply, slows actuator deployment, and increases reliance on single-source servo controllers.

This is where the 80/20 Rule becomes a critical strategic guide to achieve the desired performance. In the vast majority of industrial applications, 80% of performance needs can be effectively and safely met by a robust, reliable, and readily available servo system configuration. This represents only 20% of the total possible configurations.

The additional engineering time and lead time risk required to chase that final 20% performance boost often severely outweighs the small operational advantage. Decision-makers should push their teams to prioritize rapid deployment and supply chain stability over marginal, hard-to-source customization.

Prototypes that Fail to Scale

Using boutique or small-batch servo accessories, linear actuators, or rotary actuators in prototypes may seem fast initially but creates scaling problems. The high-volume production line often cannot source these servo drivers or actuators reliably.

When transitioning from proof-of-concept to mass production, mismatched servo output shafts, incompatible controller circuits, or custom gearbox assemblies can force full redesigns. Project timelines balloon as teams reconcile discrepancies in metal gear, duty steel gear, and shaft specifications.

Decision-makers should require that all servo components used in prototyping are vetted for long-term supply stability to avoid this costly pitfall.

Integration Nightmares and Software Lock-in

Another critical challenge is integrating servo systems with existing motion control or industrial automation platforms. Proprietary servo drivers, servo controllers, and closed-source software can create technical lock-in.

Integrating these non-standard control signals or servo pulse protocols with existing enterprise PLCs, motion servo controllers, or robotics projects often requires expensive, custom middleware or lengthy, painful debugging processes.

For seamless, rapid deployment, standardized, open interfaces are essential. The industry standard demands support for communication protocols such as EtherCAT, CANopen, or PROFINET.

By standardizing servo motor control systems and insisting on open interfaces, companies ensure new servos, actuators, and servo drivers drop into existing control systems seamlessly. This approach minimizes deployment risk while maintaining torque, speed, and rotation performance across the production line.

The Strategic Solution: Ready-to-Ship Deployment

Stability and speed can be regained by adopting a disciplined, calculated approach to component sourcing. The Ready-to-Ship (RTS) Servo Philosophy is engineered to restore predictability to your supply chain immediately.

Introducing the Ready-to-Ship (RTS) Servo Philosophy

The RTS model focuses on availability and reliability. It features a curated catalog of high-performance servo motors and servo drivers that are tested, standardized, and held in inventory for immediate fulfillment.

This approach eliminates long waits for custom servo models or unique actuators. By relying on pre-configured servo controllers and proven digital servo firmware, RTS solutions allow manufacturers to deploy systems quickly, keeping rotation, torque, and speed within precise specifications.

The RTS model is defined by a commitment to availability and reliability. It involves a curated catalog of high-performance servo motor and drive combinations. These systems are not just ‘off-the-shelf,’ they are specifically built from widely available, vetted components, rigorously tested for a broad range of industrial applications, and held in inventory for immediate order fulfillment.

The strategic focus of RTS is on core technology (efficient brushless DC motor/PMSM) paired with standardized interfaces. This focus allows suppliers to optimize their supply chain buffer stock and production scheduling for a finite, proven set of configurations, guaranteeing speed and reliability for the buyer.

From micro servos for compact robotics projects to giant servo systems for industrial automation, RTS offers a series servo line optimized for rapid integration. Standardized servo sizes, metal gear assemblies, and brushless motor cores ensure consistency, reliability, and long-term performance.

The Technical Advantage of Core RTS Components

The reliability of the RTS servo motors is that it’s built on technical discipline. High-volume manufacturers focus their efforts on proven, stable component sets.

Motor Technology: RTS servo motors are engineered for efficiency, combining metal gear, steel gear, and high-quality actuators to deliver consistent torque output.

Modern RTS servos rely heavily on Permanent Magnet Synchronous Motors (PMSM) or Brushless DC motors (BLDC). These actuators represent the gold standard for high-performance automation due to their superior efficiency, high power steering, and excellent torque-to-inertia ratio.

By standardizing the magnetic design and core mechanical specifications, suppliers ensure high-volume production is stable and reliable. Procurement teams should look for suppliers whose RTS offerings prioritize these core, highly optimized motor families.

Standardized Feedback: A major source of delay in early servos procurement is the bespoke encoder system. RTS components simplify this by utilizing reliable, standardized feedback devices, such as common absolute or incremental encoders.

These standard units simplify drive compatibility and eliminate the need for complex, custom wiring or calibration procedures. By sticking to industry-common encoder standards, you ensure interchangeability and rapid deployment.

Drive Intelligence: The servo driver is the brain of the servo controller system. RTS drives are leveraged for their intelligence, arriving pre-loaded with stable, thoroughly tested firmware and standard tuning profiles optimized for the matched motor.

This standardization drastically cuts setup and commissioning time. Instead of requiring weeks of field-tuning by specialized engineers, an RTS servo system can often be deployed and running in a matter of hours, accelerating your time-to-market.

Quantifiable Benefits for Decision-Makers

The RTS model delivers clear, quantifiable advantages that appeal directly to the executive agenda:

Risk Mitigation: By focusing on component sets that have been cross-referenced and qualified through multiple sources, the RTS model significantly diversifies the supply chain of gears. This means that a shortage from one semiconductor vendor does not automatically derail your entire product line, protecting against single-point failures in your delivery of motion control signals.

Consistent torque, rotation, and speed maintain workflow efficiency, enabling seamless integration into servo systems, actuators, and motion control networks.

Lead Time Compression: This is the most critical benefit. Ready-to-ship servos, servo drivers, and servo controllers are available in weeks instead of months.

It dramatically reduces delivery times for general servos and drives from the crippling 6-12 month range down to a matter of weeks. This compression allows project managers to adhere to realistic internal deadlines, avoiding costly delays and maintaining the competitive advantage.

Cash Flow Optimization: Long lead times necessitate massive, high-cost inventory stocking to cover the buffer period. By providing reliable delivery within weeks, the RTS model minimizes the need for organizations to tie up vast amounts of working capital in static, long-term component inventory. This frees up cash flow for other essential business investments.

With RTS, manufacturers can rapidly deploy servo motor solutions across multiple industrial actuators, from linear actuators to rotary actuators, ensuring production schedules are maintained and projects scale without delay.

Accelerating Deployment with DMKE

At DMKE, we understand that speed, reliability, and precision are critical when deploying servo systems. Our accelerated process ensures that your servo motor, servo drivers, and actuators are ready to run with minimal downtime.

Step 1: Rapid Consultation and Scope Definition

The process begins with a focused consultation to define exactly which servo hardware modifications are critical. This may include adjustments to a servo output shaft, selecting a non-standard servo controller, or optimizing rotation and torque parameters for a specific actuator.

By prioritizing essential changes, we eliminate unnecessary delays, allowing servo systems to be adapted quickly without compromising performance.

Step 2: Leveraging Modular Design

Our foundation is a robust RTS servo model built on proven brushless motors, metal gear servo assemblies, and standardized servo sizes. Customization focuses on modular elements such as servo output shafts, mounting flanges, or actuator coupling.

This modular approach avoids complete redesigns of the servo driver circuitry or controller firmware, which are often the sources of long lead times in conventional customization.

Step 3: Fast-Track Prototyping and Validation

This is the crucial stage for speed. Because our servo hardware is rigorously tested, we can validate modifications rapidly. For example, a modified servo output shaft is tested against the proven servo motor and brushless motor core, reducing prototype-to-production timelines dramatically.

This Fast-Track Validation significantly cuts weeks off the prototyping cycle. Our servo programmer tools allow precise control signals and tuning for digital servos, rotation servos, and other industrial actuators, ensuring consistent torque output, speed, and rotation across the system.

Case Study

Consider the practical difference:

- Traditional Scenario: A buyer needs a servo motor with a 5mm longer servo shaft and a specific servo controller configuration. They approach a traditional vendor. The vendor must re-engineer the entire motor drawing, re-certify the new mechanical stress points, and re-validate the motor performance based on the structural change. This results in a 9-month lead time for a full custom design, including testing.

- Rapid Scenario (with DMKE): The buyer selects an RTS servo model and requests only the shaft modification. Because the base electronics performance of an electric motor is proven and certified, we only need to validate the mechanical integrity of the modified shaft within the modular design envelope. This results in a validated prototype delivery in four weeks, followed by rapid scaling to production. This modular process turns a three-quarter-year delay into a single-month waiting period, maintaining project velocity.

For those critical projects requiring targeted modifications, partnering with a provider that guarantees speed and modularity, like the rapid customization process detailed on our custom products page, is a competitive imperative.

| Metric | Traditional Shipping | Ready-to-Ship (with DMKE) | Impact |

| Project lead time | Long | Quick | Maximized deployment speed |

| Supply chain risk | High | Low | Stability & reliability |

| NRE (engineering cost) | High | Low | Lower initial investment |

| Scalability | Uncertain | Proven | High-volume success |

Conclusion

The era of leisurely electric motor control procurement is over. Volatility, long lead times, and the high cost of delay demand a proactive and dual-pronged strategic response. The solution is clear: Ready-to-Ship (RTS) servo systems solve the supply chain instability challenge for the majority of industrial needs by offering stability, predictable delivery, and verified performance.

RTS servo motors, servo drivers, and standardized servo controllers solve supply chain instability by offering predictable delivery and verified performance. From brushless motors to metal gear servo assemblies, these servo models are engineered for immediate deployment.

The most effective way to secure your production pipeline is to leverage components that are engineered for availability. Stop forecasting 12 months out. Start deploying today. Explore our RTS catalog for immediate needs, and for projects requiring targeted, rapid modifications, learn more about our accelerated, professional process.