Servo worm gear motor

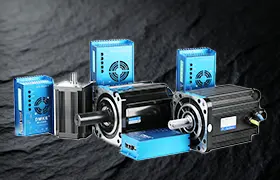

- DMKE

- Brushless Servo Motor

- Servo worm gear motor

These motors offer the excellent positioning and feedback of a servo, enhanced by the worm gear’s high torque multiplication, right-angle configuration, and inherent self-locking for holding loads securely.

About Servo worm gear motor

The Servo Worm Gear Motor, powered by advanced BLDC technology, is a cornerstone of precision in both aerospace and medical fields. In aerospace, it ensures reliable performance for critical applications like flight control actuators and satellite positioning systems, where high torque, minimal backlash, and leak-proof operation are vital. Similarly, in medical devices such as surgical robots and imaging systems, it provides the smooth, quiet, and accurate motion essential for patient safety and procedural success. The integrated BLDC motor enhances these applications with its superior advantages, including high energy efficiency for extended operation, precise electronic control for unparalleled accuracy, a long maintenance-free lifespan, and compact high-power density ideal for space-constrained and demanding environments. This combination delivers unmatched reliability and performance for mission-critical tasks.

| DC Servo Gear Motor | |

| Rated Power(W) | 50W to 10KW |

| Rated Voltage(V) | DC12V,24V,36V,48V,72V,96V,310V |

| Flange Size Range(mm) | PLF42 to PLX242 |

| Rated Torque Range(N.m) | 0.5 to 4220N.m |

Gear Ratio | 1st stage:3,4,5,7,10 |

| 2nd stage:12,16,20,25,28,35,40,50,70 | |

| 3rd stage:64,80,100,125,140,175,200,250 | |

| Remark:custom-made dc servo motors are workable for us | |

The Unseen Guardian of Precision: Servo Worm Gear Motors

In environments where failure is not an option, from the vastness of space to the sterility of the operating room, the demand for absolute reliability and precision finds its answer in the Servo Worm Gear Motor. This robust actuator has established itself as the foundational element for motion control in the most demanding aerospace and medical applications.

Aerospace Actuation & Satellite Systems

In flight control and landing gear mechanisms, Servo Worm Gear Motors provide high-torque, compact actuation with inherent self-locking capability. This crucial feature prevents back-driving, ensuring control surfaces and landing gear remain securely in position without additional braking systems, a vital safety function in aviation and satellite orientation.

Surgical Robots & Operating Tables

For surgical robots requiring micron-level accuracy and operating tables that must move smoothly and reliably, the Servo Worm Gear Motor is indispensable. It delivers smooth, continuous motion with minimal vibration and exceptional positional repeatability, enabling the precise movements that are critical for minimally invasive surgery and patient positioning.

The Unmatched Advantages of Servo Worm Gear Technology

Inherent Self-Locking & Safety

The worm gear design naturally resists back-driving, providing a failsafe mechanism that holds loads securely in place without power. This is paramount for patient safety in medical beds and for maintaining the position of aerospace control surfaces.

High Torque & Compact Design

The technology delivers a high torque output from a compact and space-efficient package. This allows engineers to design powerful actuation into the tight confines of aircraft wings, robotic arms, and portable medical devices.

Exceptional Reliability & Low Maintenance

With robust construction and a design that minimizes wear, Servo Worm Gear Motors offer a long operational life with minimal maintenance needs. This reduces downtime for critical medical equipment and ensures long-term reliability in inaccessible aerospace systems.

Smooth, Quiet & Precise Operation

The gear engagement provides inherently smooth motion transmission, resulting in low noise and vibration. This is essential for patient comfort in medical settings and for the stability of high-precision instrumentation in both medical and aerospace labs.

Why DMKE

In-House Production with 150+ Workforce

Wide Power Spectrum: 5W to 25KW Brushless DC Motors

16+ Years of Motor Industry Expertise & Application Knowledge

Integrated Motor & Drive Systems for Seamless Responsibility

Free Expert Pre-Sales Engineering & Selection Support

ISO9001, CE & RoHS Certified Quality Assurance

40+ Patents & 20+ R&D Engineers for Custom Solutions

Professional & Responsive After-Sales Technical Support