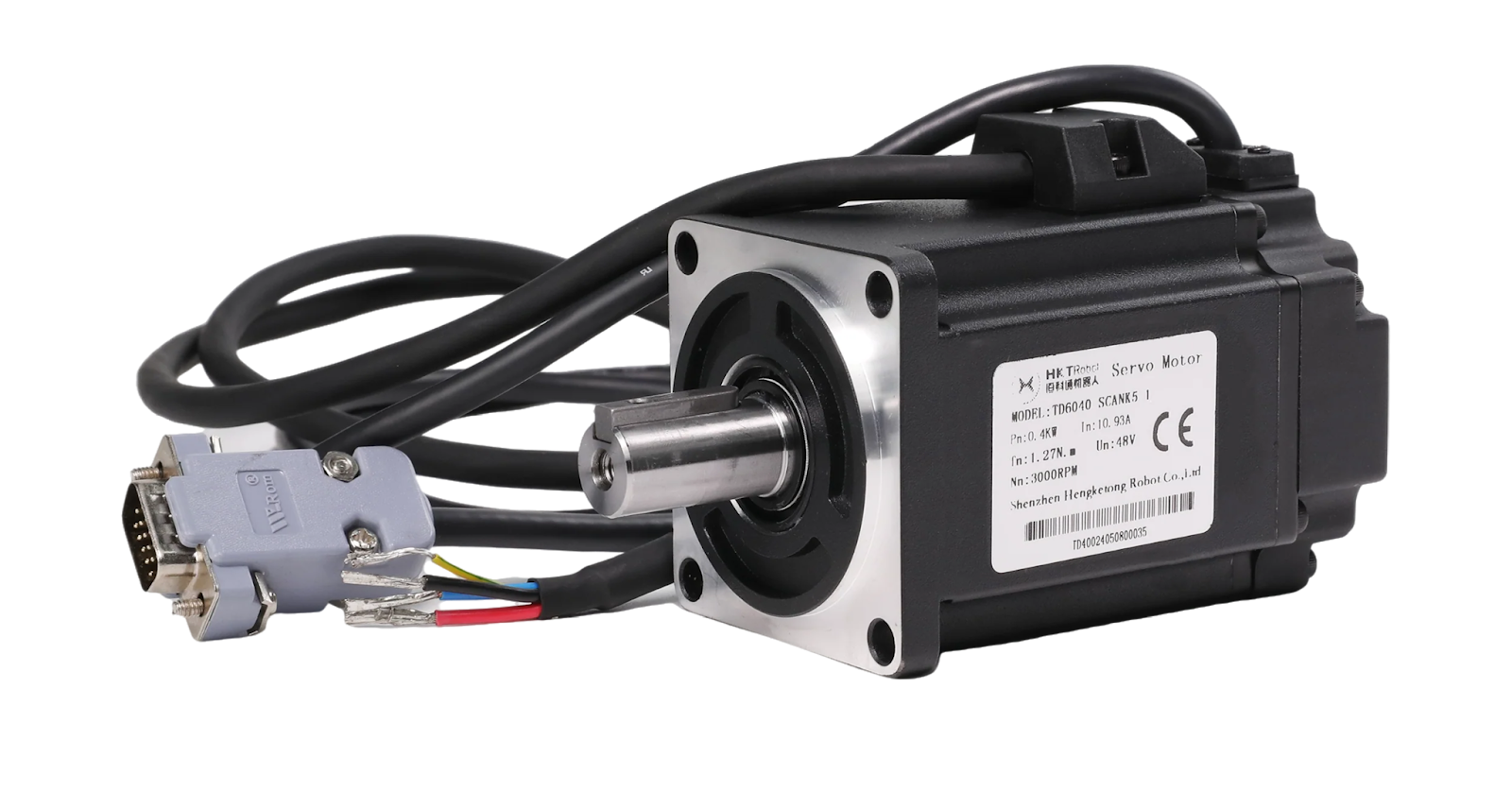

When you walk into a modern factory, chances are you won’t notice the unassuming motors quietly doing the heavy lifting. Yet those motors, known as servomotors, are the invisible workhorses of automation.

A servomotor responds, adjusts, tweaks, and repeats with razor‐sharp precision so that machines move exactly how they should, when they should. In many ways, they serve as the core actuators of industrial automation, turning command signals into motion, torque, direction and speed with finesse.

Why are they so indispensable? Because in a world where factories aim for more output, tighter tolerances, and zero downtime, servomotors deliver what simpler actuators simply can’t. Compared with a stepper motor or a hydraulic cylinder that might be strong or simple, a servomotor brings feedback, responsiveness, and control. This makes it enable everything from CNC machines cutting components at micrometer scale to collaborative robots moving safely alongside humans. Their role in automation is rarely flashy, but it’s foundational.

Here’s the telling stat: the global servomotor (and drives) market was estimated at around USD 20.2 billion in 2024 and is projected to grow markedly from there. That growth speaks not just to demand, but to the fact that evolution is required. With all these demands and pressures, the question becomes: how will servomotors evolve by 2025 and beyond to break through these bottlenecks?

This is exactly where our focus turns: the latest innovations reshaping servomot technology. In the following sections, we’ll explore three major directions of advancement like artificial intelligence, breakthrough with material, and integration for ultimate energy efficiency. Together, they redefine what servomotors can do.

1. AI Driven Servomotors and Adaptive Control

Smart servomotors that learn, predict, and self optimize.

When we think about the core of a motion-system, the humble servomotor is still doing the heavy lifting. But what if that same motor could also think and adapt as it spins? That’s exactly what the first major innovation in 2025 is all about: servomotors that integrate artificial intelligence and adaptive control to become fundamentally smarter.

The rise of AI-driven motion systems

In the past, setting up a motion system meant manually tuning parameters – things like proportional, integral and derivative (PID) gains, adjusting for load changes, friction, vibration or varying duty-cycles.

Traditional controllers could do a good job, but they relied on fixed settings and human input. Researchers recently pointed out that reinforcement-learning techniques applied to servomotor control can “train an agent to produce a duty cycle according to the servo error” and adapt as operating conditions change.

Now imagine a servomotor drive with an embedded processor, edge-AI algorithms and continuous feedback from sensors. It’s watching the motor’s behavior, comparing it to previous cycles, spotting small discrepancies, and then automatically tuning itself. According to a motion-control industry article: “AI in servo control is used in learning algorithms that analyse the move profile’s specific feedback… allowing the system to identify inconsistencies undetectable to the human eye.”

This shift from static tuning to adaptive, real-time learning means a lot for manufacturers: less commissioning time, fewer field-adjustments, and better performance from the first run. Plus, AI-enabled tuning helps when loads or magnetic conditions change over time (which they always do).

Machine learning for performance optimization

Let’s drill into how this plays out in practice. Machine learning is enabling three very real benefits in servomotor systems:

- Adaptive tuning on the fly: Suppose you have a system where load changes rapidly (think packaging equipment switching products, or a machine handling different parts every cycle). A traditional servo may need returning every time the profile shifts. With AI, the motor drive senses the shift and adjusts control parameters in milliseconds to maintain stability and accuracy. In one study of servo systems, adaptive control via reinforcement learning showed smaller tracking errors than conventional methods.

- Predictive maintenance and health monitoring: AI algorithms can monitor vibration, temperature, current draw and performance trends over time. For example, one industry article showed how motion-control AI used feedback data not only to tune motion, but also to detect when bearings might be wearing out or when alignment is slightly off before a breakdown happens. Predicting failures ahead of time means unplanned downtime drops and maintenance becomes proactive.

- Energy and efficiency improvements: With optimal tuning and fewer errors or overshoots, the system runs more cleanly. As the motion becomes smoother and more stable, energy wasted from oscillations, heat or correction cycles goes down. The same article from techbriefs noted that AI in servo control “brings many other benefits, including energy efficiency, predictive control, and full autonomous systems.”

Industrial applications

Where is this seeing real impact right now? Quite a few places, actually.

In robotics (particularly collaborative robots or “cobots”), the need for dynamic response and safe interaction with humans means motion must adapt instantly. AI-based servomotor systems help these robots adjust to slight changes in payload, friction or position without human re-tuning. As one article stated, AI and machine learning are “increasingly integrated into motion control systems, pushing the boundaries of precision and efficiency.”

In high-throughput manufacturing (for example semiconductor manufacturing or packaging lines) – where cycles are fast and loads shift or parts change – the ability of a servo system to self-tune means less setup time and fewer interruptions.

In critical precision tasks where positional accuracy and smooth motion are non-negotiable, such as surgical robots or micro-assembly machines. While the full scale of AI integration is still emerging, the potential for AI-driven servos to reduce positional error by 10-30% is often cited in industry trend reviews.

In short, AI-integrated servomotors are becoming less of a “nice to have” and more of a must-have for operations demanding agility, precision and intelligence.

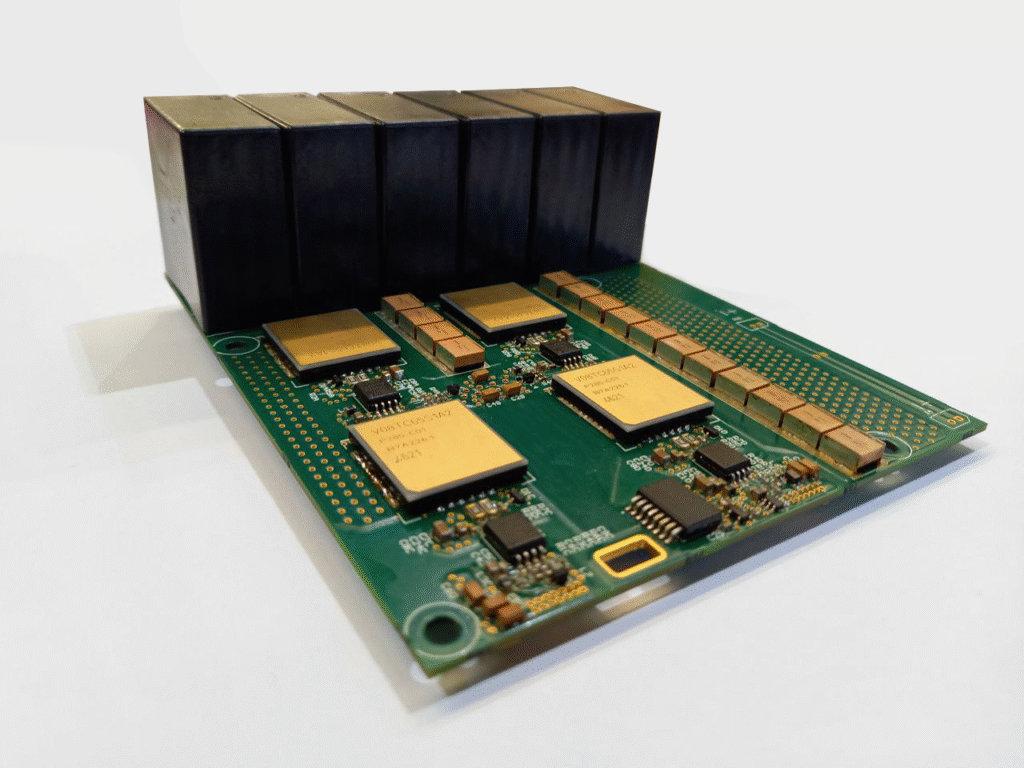

Supporting technologies

This shift is made possible not just by clever control algorithms, but by a supporting ecosystem of hardware and connectivity. For example, edge AI chips are embedded in motor drivers. Instead of sending all data to a cloud and waiting for instructions, the intelligence is embedded locally. This means lower latency, higher reliability, and less dependence on network connectivity.

The servomotor system sends ongoing performance data to plant analytics platforms. Patterns of performance drift, maintenance need, tuning adjustments become visible across many motors and machines, driving continuous improvement.

The drive firmware supports parameter updates, feedback logging, anomaly detection modules and remote update capability. Together they allow the servomotor to evolve in situ, not only at initial installation.

Impact & measurable gains

It’s all fun and games but does it actually have any impact?

Efficiency improvements in motion systems of 10-15% less energy waste have been reported when systems self-optimize inertia, torque, and load response. Calibration and downtime for manual tuning drops. Therefore, engineers report fewer line stoppages for “motor tuning” after adopting adaptive control.

Servomotor system lifespan extends: by predicting and avoiding stress conditions, wear is reduced, meaning fewer premature replacements or rebuilds. In one case study in high-speed automation, adopting AI-enabled servo drives reduced unplanned downtime and improved product consistency significantly.

Conclusion

Overall, this first innovation axis (AI integration and adaptive control) is turning servomotors from fixed-performance devices into smart actuators that grow more efficient, responsive and reliable over time. In our next section we’ll explore how new materials and structural breakthroughs are further reinforcing that evolution.

2. New Materials and Structural Breakthroughs

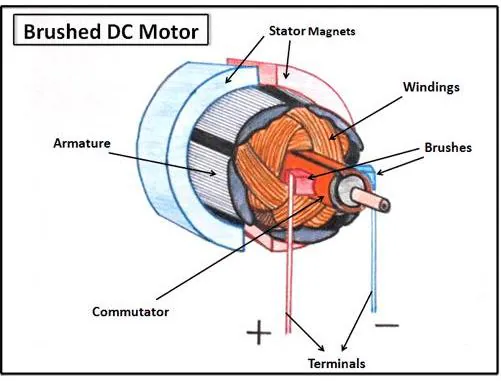

When you dig into what actually makes a servomotor tick, it is clear that it’s not just about clever control algorithms or firmware updates. It’s also about the physical hardware, the materials, the layout, the construction.

For the latest generation of servomotors (or “servos”) in 2025, the push toward new materials and structural breakthroughs is becoming just as pivotal as the intelligence layered on top of them.

Why materials matter

Think about it: a servomotor is a compact-high-precision actuator, expected to move quickly, stop sharply, reverse, hold position, respond to load shifts, often under industrial stress. All of this stresses the materials involved i.e., rotors, stators, insulation, magnetic cores, bearings, housings, thermal interfaces.

A modest improvement in material properties can ripple into major performance gains: higher torque densities, lower inertia, faster response, smaller form factors, less heat. According to a recent overview of servo motor structure, modern designs allow very compact, space-saving construction with high dynamics and precision.

But in many existing servomotor lines, materials have not kept pace with evolving demands. The old iron cores, standard copper windings, and basic steel housings still dominate. That means limitations: thermal buildup, limited switching frequency, higher weight and inertia, more vibration, less ability to shrink footprint. With industries asking for faster cycle times, smaller machines, more flexible automation, the demands have forced a rethink.

Hence for 2025 the focus is on three big sub-areas: semiconductor breakthroughs in drive electronics (especially gallium nitride), mechanical materials for housing and structure (composites, alloys, lightweight designs), and improved electromagnetic/magnetic architecture (advanced cores, better windings). Let’s explore each.

Breakthrough: Gallium Nitride (GaN) and next-gen semiconductors

If you look at the “brain” of the servo drive (the power electronics that convert energy, switch current and deliver torque) the move from conventional silicon MOSFETs to gallium nitride (GaN) power devices is a major leap.

GaN devices switch far faster, handle higher frequencies, and have much lower conduction and switching losses. These motor drivers are being adopted for robotics, drones, e-mobility, and industrial motors because they offer smaller, lighter and more efficient solutions.

What does this mean for servomotors? First, lighter drive electronics mean you can integrate more of the drive into the motor housing (or closer), reducing wiring, improving response, and shrinking packaging.

Second, lower heat loss means less cooling infrastructure, less thermal drift, and better reliability. Third, faster switching means you can push higher bandwidth control, finer resolution, and better dynamic response. So the material innovation isn’t just “new metal” but “new semiconductor” – the material of the electronics is enabling structural benefits too.

Lightweight and high-strength composite housings

While the electronics get smarter, the mechanical housing of the servomotor is also changing. Traditional steel or cast aluminium frames are being challenged by composite materials and advanced alloys that reduce weight and inertia while maintaining stiffness and thermal robustness.

One trend flagged in industry commentary is “lightweight composite materials for even greater power density” as a future trend of servomotor technology.

Why does this matter? A lower-inertia rotor/housing structure accelerates and decelerates faster, reduces overshoot, improves stop-to-go performance. A lighter housing allows for smaller machine axes or robot arms without compromising stiffness. And better thermal conductivity or thermal isolation in new materials can reduce hotspots and improve life in high duty cycles.

Adoption of carbon-fibre reinforced polymer housings, ceramic composites, or hybrid alloy/composite structures, although not yet ubiquitous, are increasingly seen in high-performance motion systems. They matter when every gram, every millisecond, every cycle counts.

Advances in coil design and magnetic architecture

Beyond the outer shell and electronics, the heart of the servomotor (the rotor, stator, windings, magnetic cores) is also undergoing material and structural improvements. Engineers are turning to high-energy permanent magnets, amorphous core materials, optimized winding geometries, additive manufacturing for windings, and improved insulation materials.

And on the magnetic side, using materials that reduce eddy current losses (for example amorphous or nanocrystalline cores) enables higher switching frequencies (which match well with GaN drives) and better efficiency. Also, winding methods that maximize copper fill, reduce stray inductance, and reduce coil losses allow higher power density in the same footprint.

Composite materials for the stator core or hybrid lamination techniques are beginning to appear in research and higher-end industrial motors. These structural breakthroughs mean that a given size of servomotor can now deliver more torque, more speed, or both.

Real-world context and why it matters in 2025

In many manufacturing lines, automation is evolving from “rigid, repetitive runs” to “flexible, fast change-over” systems. Robots must pick and place lighter and heavier objects, machines must ramp up and down, trajectories must be tighter with less margin. In such environments, servomotors built on decade-old materials begin to limit performance: inertia may be too high, cooling may be insufficient, thermal drift may degrade precision.

By contrast, if you deploy a servomotor built with the latest materials, you unlock meaningful productivity gains. Smaller machines, faster cycles, less energy consumption, reduced maintenance.

Globally, as automation spreads, manufacturers are under pressure not just to keep costs down but to reduce energy consumption and carbon footprint. The materials and structural breakthroughs directly contribute there: less energy wasted as heat, fewer materials used for the same or better performance, longer machine life. And in sectors like electric vehicles, aerospace, clean manufacturing, servomotors have to meet higher standards for weight, for thermal performance, and for durability.

Summing up

So this second major innovation direction (new materials and structural breakthroughs) is about rethinking the hardware of the servomotor so that it can deliver more with less. By adopting gallium nitride electronics, lightweight composite structural components, and next-generation magnetic and winding architectures, 2025 servomotor systems aren’t just “smarter” (that was the first innovation axis) but also stronger, faster, more efficient and compact.

With that foundation in place, the following section will turn to the third major innovation axis: integration and ultimate energy efficiency, where these material improvements and structural gains feed into system-level designs and energy-smart architectures.

3. Integration and Energy Efficiency

The era of the servomotor being simply an isolated actuator is ending. In 2025, the real leap forward comes from system-level integration, energy recovery, and smarter digital control. When drives, motors and sensors work together intelligently, the gains go far beyond just better motion. They start to bring down energy use, simplify installation and open entirely new possibilities for automation and sustainability.

The shift toward system-level efficiency

Historically, when engineers talked about servomotors, the focus was often on the motor itself: torque, speed, size, control loop. But the real gains now are coming when you stop thinking of the motor in isolation. Instead, you see the entire motion-control ecosystem i.e., the motor, the drive, the encoder, the wiring, the power electronics, and the energy flows act as a single integrated system. That shift is huge because the greatest efficiency improvements occur when you optimise across components rather than each in isolation.

In a recent industrial-automation insight, it was observed that modern servo drives not only reduce energy during normal operation but also enable energy feedback and reuse when decelerating loads.

What does this mean practically? It means that rather than the motor simply consuming energy and dissipating waste as heat when slowing down, the system might capture that energy, reuse it elsewhere in the plant or internally, and reduce the overall grid draw. In one warehouse application reported by SEW‑Eurodrive, an “energy-efficient SRS” system fed regenerative power back into the bus and cut energy consumption by up to 50%.

Energy regeneration and reuse

Let’s focus on this idea of regeneration: When a robot arm, conveyor, or actuator slows down or descends, it has kinetic energy. Traditionally that energy is lost: converted to heat, sometimes dumped in a resistor, or simply wasted. In newer servomotor systems the actuator becomes part of an energy loop. The kinetic energy is converted back to electrical energy and either returned to the DC bus, used on another axis, or sometimes sent back into the power grid.

The data show that regenerative systems can reclaim a significant amount of otherwise-wasted energy. For example a variable-frequency drive architecture with feedback capability claimed up to 50% of braking energy that would have been wasted.

Imagine a machine line with many axes doing repeated up/down, start/stop moves. Every deceleration is an opportunity not just for cooling down but for recovering energy. That recovered energy can reduce the motor’s net draw, reduce waste heat (which often becomes a thermal management problem) and shrink the footprint of the power supply system.

Integration

Another important theme in this innovation axis is integration. Think of a servomotor system that is no longer “motor here, drive there, wiring everywhere, separate controller” but instead is a compact, unified mechatronic package: motor, drive electronics, encoder, possibly even controller, all in one. Some vendors are packaging these systems to reduce wiring length, simplify installation, lower electromagnetic interference (EMI) and increase reliability.

Integration brings multiple benefits. Smaller packaging means lower parasitic losses (less cabling, fewer connectors). Fewer discrete components mean fewer points of failure and easier maintenance. From an energy efficiency perspective, shorter signal paths, fewer transitions and optimized power electronics all add up. When you have a servo motor with embedded drive and integrated controller, you reduce the “overhead” that often eats energy in less-optimized systems.

In a modern factory where space is premium, extra wiring, control cabinets, and cooling systems add up both in cost and energy use. Integrated designs reduce the “non-motion” energy overhead. This matters when you think at scale: hundreds of servo axes in a production line. The cumulative effect of smaller, smarter, integrated systems can be quite large.

Sustainability and green manufacturing

We live in a time when every manufacturing line must not only perform but also be sustainable. The global push to reduce carbon emissions, energy waste, and resource use means that motion systems are under scrutiny. Advances in servomotor technology are now deeply aligned with these goals.

The combination of regenerative energy reuse, integrated and compact design, and smarter electronics contributes to three major sustainability benefits:

- Lower energy consumption per unit produced: When a servo axis uses fewer watts for the same motion, and reuses energy on deceleration, its net energy per cycle drops.

- Reduced cooling and auxiliary energy demand: Lower heat means less demand on cooling systems, which often add considerable load in automated plants.

- Longer system life and fewer replacements: Integrated, efficient systems generate less heat and stress, meaning bearings, electronics, and motors last longer, reducing waste and downtime.

Because motion systems often run 24/7 in factories, even a 10-20% saving per axis or per line translates to large annual savings. Multiply that by hundreds or thousands of axes across global operations and the impact is considerable.

Case studies

Let’s bring this to life with a couple of practical examples you’d expect to see in 2025 setups.

We’ll start with example A on the electric vehicle manufacturing line. In an EV manufacturing plant, robotic arms, transfer systems and conveyors are constantly moving heavy assemblies, stopping and starting, changing direction. If each servo-actuated axis incorporates regenerative capability, the deceleration energy of a robot arm lowering a heavy assembly can be recovered and used for the next acceleration. Over thousands of cycles each day, that adds up. In one reported stacker crane system the regenerative supply unit supported lowering movements and returned energy, reducing line consumption by up to 50%.

Example B will focus on autonomous logistics systems. In a smart warehouse with automated guided vehicles (AGVs) and multi-axis lifts, these systems often deploy servomotors for precise motion. But the lifts and transfer devices decelerate frequently. By integrating drives with feedback, regenerative ability and smart coordination of axes, the system not only uses less energy but also reduces grid draw at peak times.

These examples indicate a trend where companies are actively redesigning motion systems around energy reuse and integration rather than just performance.

Why it matters and what to watch

You may ask why we are focusing on integration and energy efficiency as the third innovation axis. The answer lies in how manufacturing and automation are evolving. Speed, precision and flexibility have been major goals. But now sustainability, cost of ownership, and system-level optimisation are becoming equally important. If a servomotor delivers top performance but draws too much energy, generates too much heat, or complicates the infrastructure, it may fail in the market.

In 2025, innovation in servomotors is about running smarter and cleaner. That means tracking not only motion metrics but energy metrics, designing for reuse, minimising waste. System designers must ask: how can this axis recover energy? How compactly can we package the drive? How can we simplify installation and cooling? How can we reduce the lifecycle cost (including energy and maintenance) of this motion system?

When you scale across an entire factory or across multiple plants, the impact is material. It might mean millions of kilowatt-hours saved per year, reduced cooling costs, smaller power infrastructure, and fewer maintenance interventions. These translate to economic payback, lower carbon footprint, and competitive edge.

Summary

In this third innovation direction i.e., integration and ultimate energy efficiency, servomotors are evolving from components into system enablers. The combination of energy regeneration during braking / deceleration, compact integrated mechatronic designs, and a strong alignment with sustainability goals means the motor-actuator-drive-controller chain is becoming far more efficient and effective.

In the next and final section, we’ll wrap up the big picture: what all of this means for industry, how these innovations will impact design, operations and business strategy, and how forward-looking organisations can position themselves to benefit from the servomotor revolution.

Make your automation systems smarter and greener. Contact DMKE today to schedule your free consultation and find out how our next-gen servomotor integration can reduce your energy costs and installation effort.

Conclusion and the bigger picture

As we wrap up our look at the latest in servomotor innovation, it’s clear that AI integration, advanced materials, and system-wide energy efficiency are not just incremental improvements. Together, they are redefining how automation operates, making machines smarter, faster, and more efficient.

The global servomotor market continues to grow, with industrial robot servomotors expected to rise at about 8.3% annually over the next decade. This growth reflects a clear shift: manufacturers want systems that do more than move. They want systems that adapt, optimize energy use, and deliver actionable performance data.

For your business, that means deploying machines that respond in real time, reduce energy waste, and integrate seamlessly into modern production environments. The right servomotor technology can transform your operations, improve uptime, and give you a competitive edge in a rapidly evolving market.

Ready to see how these innovations can work for you? Check out the product range of DMKE or schedule a consultation with our experts to explore solutions tailored to your needs.