The automation environments and industries are becoming more and more demanding each passing day. As a result, servo motors, being the backbone of most automation systems, are facing increasing pressure.

Take robotic arms, for example, that are expected to move faster without losing control and accuracy. Similarly, in AGVs, unpredictable shifts in external loads are expected to be handled properly without the AGV losing its stability. As for packaging and assembly lines, it is expected that they will now run longer cycles without any tolerance for their positioning and operation.

All of these demands make the job of a motor extremely difficult and demanding. This is where high-torque servo motors come in, offering productivity, reliability, and efficiency like never before.

For engineers and industry owners, choosing the right kind of servo motor is rarely a straightforward and easy task. It comes with its own challenges, and many times, stakeholders end up investing in devices that look great on paper but fail to deliver practically.

When you go out searching for a high-torque servo motor, you’ll come across several models that look similar in terms of their specs and features. Most of them will have the same voltage range and torque numbers, as well as similar speed ratings.

However, once you install them, their real-world performance might be entirely different from what was initially promised. Continuous loads lead to dropped torques, and overshoots are common during directional changes. In many cases, the motors will struggle to maintain accuracy after delivering precision for a few hours.

All of these issues often have their roots in factors that are not easy for buyers to judge from a single spec sheet alone. Some of these factors include encoder precision, torque behaviour, material quality, as well as the manufacturer’s consistency of production. The way you source your motors also adds a layer of complexity to the entire scenario.

In industries, procurement teams are frequently met with suppliers who are unable to ensure stable delivery on every shipment. There are inconsistent batch qualities and a lack of back-end testing. Most manufacturers often fail to meet the strict standards that are pertinent to heavy-duty applications.

For companies that are running larger fleets and sourcing their motors in bulk, even minor issues have huge impacts. Variations between different batches can lead to calibration mismatches, downtime, and several other issues. In the competitive world, these problems might seem small on the surface, but they are extremely grave and can escalate quickly.

This explains why sourcing high-torque servo motors is becoming so difficult nowadays. It is not just about purchasing a system’s part, but rather about making a strategic decision with several factors associated with it.

Procurement teams in the automation industry now focus on long-term reliability, real-world performance, and customisation capabilities of a motor before investing in it. Another important factor that many procurement teams now consider is a proven QC process rather than just relying on spec sheets and documents.

In short, if you are investing in a servo system, especially in bulk, getting consistent delivery is extremely important. It not only causes smoother motion and fewer breakdowns but also leads to predictable operational costs and enhanced efficiency in the automation industry.

This article will not only help you understand the benefits of a bulk purchase but also explain the major parameters that can help you determine whether or not a servo motor is worth investing in.

Technical Analysis: Understand Parameters for Smart Selection

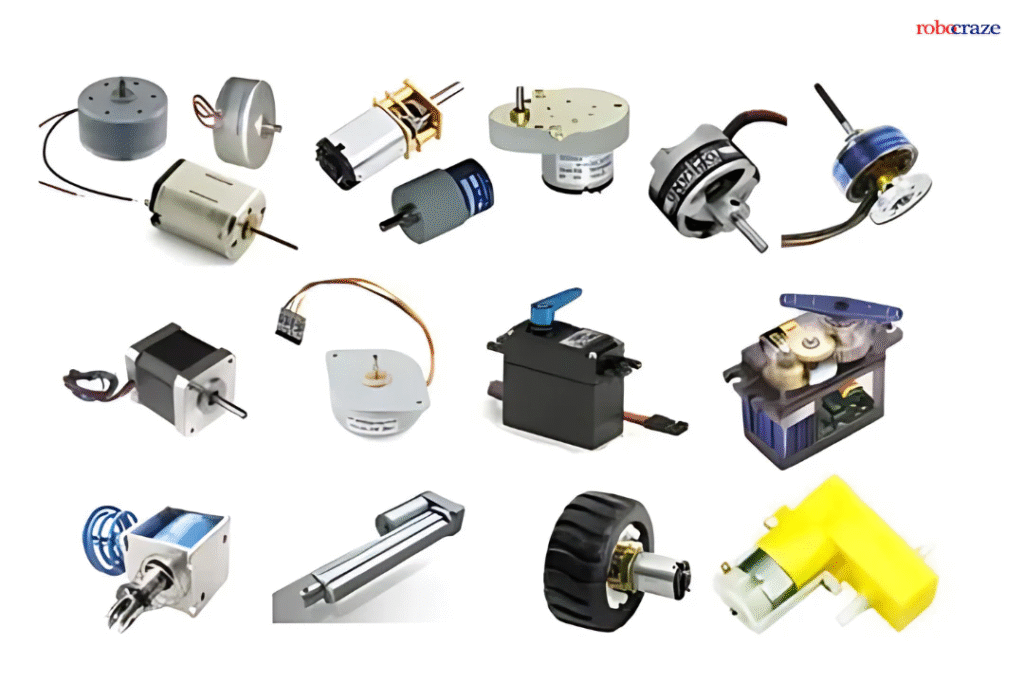

As explained above, selecting the right kind of high-torque servo motor is not simple. It’s not just about looking at the numbers or specs and matching them with the standards you have in mind. Rather, it’s about the motor’s performance in real-world operations.

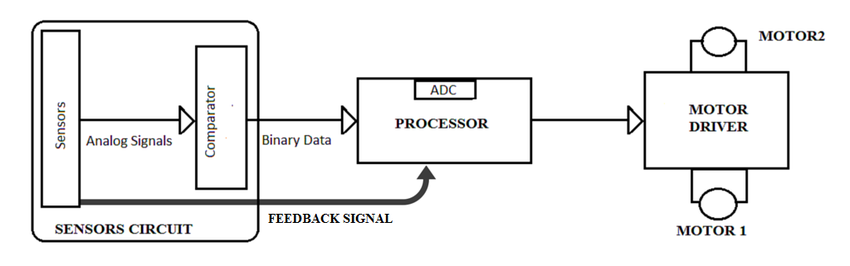

The performance and everyday role of a servo motor depend on how it behaves across its entire functioning tenure. From the torque speed curve to how a motor reacts to it and how precisely it reads positions through the encoder, every little detail matters.

It is also important to see how well the device will withstand environmental conditions during its operation. All of these factors and many others directly determine the accuracy, stability, and reliability of a motor and help you understand whether or not it will suit your purpose.

Many inexperienced and unaware buyers often commit the mistake of focusing only on the rated torque or the continuous load capacity of a motor. These numbers, even when correct to a certain extent, only tell a part of the story.

Peak torque determines how confidently a motor can handle sudden force spikes. On the other hand, the overall curve rating shows whether the motor can ensure stability during rapid speed changes or not.

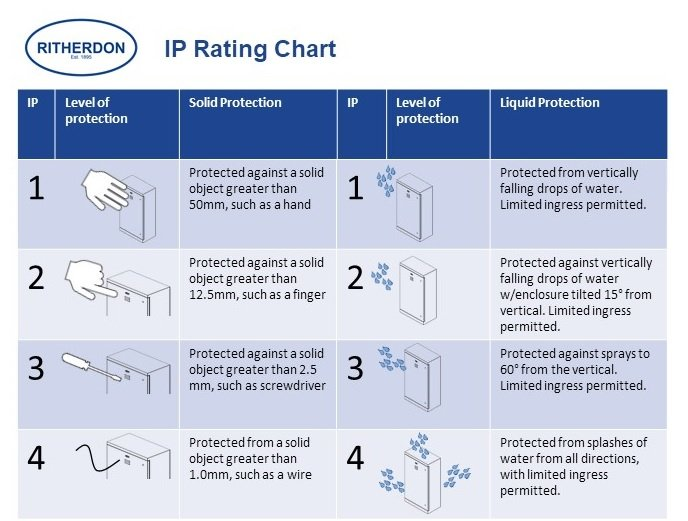

Similarly, encoder resolution determines the smoothness and accuracy of the motor at each moment, which makes it particularly important for robotics. If you want to procure a motor for dusty, humid, hot, or vibration-heavy environments, the IP rating becomes extremely critical.

A proper understanding of all these parameters, as well as the reason you are purchasing the motor, helps eliminate all the guesswork from procurement and helps you choose an item that not only sustains and is worth using, but is also efficient enough to deliver what is expected of it.

Below, we will discuss all the important servo motor selection parameters for you to make your next procurement easier and straightforward.

1- Rated vs. Peak Torque

Rated torque is the torque that represents the force your servo motor can deliver continuously without overheating or losing its stability. This torque directly affects how well the motor will perform under a steady, unbothered, uninterrupted, and repetitive load.

On the other hand, Peak torque refers to the short bursts of force available for moments when the load suddenly shifts or increases. Peak Torque is often required in cases of quick acceleration, abrupt stops, or heavy lifting.

Both these torques matter equally for a motor to align with real-world usage. Underestimating Peak Torque often leads to overheated and suddenly stalled devices. On the other hand, not taking rated torque seriously results in long-term failure of the motor.

2- Understanding the Torque-Speed Curve

Before you understand how Torque Speed Curve matters for a motor and its stability, it’s important to understand what it exactly is. In simplest terms, this curve is one of the most straightforward indicators of a motor’s real-world capacities.

Imagine two motors with the same torque rating. If they are behaving very differently under rising speeds, the reason could be the difference in their Torque Speed Curve. In high-demanding environments that need higher torque applications, usually a strong output in the lower to mid-speed range is required.

On the other hand, in robotics and fast-moving systems, stable torque is preferred. During the motor speed-up, predictable and smooth Torque Speed Curves make the machine respond consistently under dynamic motions, and also ensure fewer jitters and drop-offs or delays.

3- Encoder Resolution and Control Accuracy

Understanding the motor’s encoder resolution helps you understand how precisely it will know its position. A higher resolution means the motor will deliver smoother and better control moments, especially under micro-adjustments or when multiple axes have to stay organised and synchronised.

In robotics, AGVs, and other automated inspection equipment, lower resolution often causes small positioning errors. These issues might disrupt the entire working of the system and accumulate into bigger problems over time.

Selecting the right encoder means that you are ensuring control accuracy of the motor and are also ensuring that the entire motion system will remain accurate and reliable even during long duty cycles.

4- IP Rating & Environmental Protection

Wherever the motor has to work and stay for a longer duration has a lot of effect on its overall lifespan as well as its performance. Motors working in dusty, moist environments and facing intense vibration and temperature changes can experience degraded performance if they are not protected enough to work in those environments.

Whether or not a motor is suitable for a specific environment is often determined by its IP rating. For example, an IP54-rated motor will be suitable for neat indoor environments only. AGVs, packaging lines, and outdoor motors need to have at least IP65 or higher ratings for them to stay reliable and offer longevity.

Having a motor with the correct IP level saves you from facing premature wear, improves the overall heat management of the motor, and ensures consistent performance in all kinds of surroundings.

Key Selection Parameters Comparison

| Parameter | What It Affects | Recommended Range |

| Rated Torque | Continuous load | Medium–High |

| Peak Torque | Overload scenarios | 2–3× rated torque |

| Encoder Resolution | Precision | 14-bit+ for robotics |

| IP Rating | Durability | IP65+ for AGVs |

What Makes DMKE a Reliable Choice?

As a procurer of servo motors, especially when buying in bulk, you probably want only two things from your supplier: straightforward answers and a motor that delivers consistent and accurate performance throughout. This is where DMKE comes in.

We won’t give you vague promises with number-heavy data sheets when inquired about a motor. Rather, we focus on predictable quality motors made to handle specific kinds of loads, along with parts and controllers that are compatible with those motors. Not only that, we also offer reliable after-sales support that actually helps you instead of leaving you hanging.

For buyers who are tired of fluctuating prices, uneven build quality, and irresponsible suppliers who will just disappear after taking their money, DMKE’s stability and promise of commitment are what make a noticeable difference.

Our goal isn’t just to oversell our products in bulk, but rather to make sure that our customers know exactly what they are getting. This is why all our equipment comes with properly defined specifications and usage ranges, and is rigorously tested prior to sale.

Key Benefits: 6 Real Advantages of Volume Procurement with DMKE

You should only move forward with volume procurement of high-torque servo motors when your manufacturer can guarantee consistent performance, reliability, and precision across all batches. At DMKE, we ensure meeting this exact requirement. Below are some of our distinguishing features that make us reliable suppliers for all your volume procurements.

1: Lower Costs Through Full In-House Production

Under in-house production, the entire process is controlled under the same roof, which removes hidden costs and variables that often lead to inconsistencies and delays. With in-house production, costs, lead times, and post-sale support remain stable and consistent, keeping you free from worries.

2: Guaranteed Stable Delivery & Supply Chain Security

For businesses that have to place consistent orders in bulk, delayed shipments and inconsistent availability become one of the biggest challenges. DMKE has multiple production lines along with a structured inventory to cater to bulk orders. This makes sure that you can plan your future automation projects without the fear of delays and unexpected delivery issues.

3: Deep Customisation Capabilities

Bulk orders are often facilitated by suppliers, especially to help customers get a motor that is custom-made to suit their needs. With DMKE, you can dictate everything about your motor from shaft lengths to encoders and more.

4. Consistent Quality Across All Units

Every piece produced at our plant leaves for the customer’s destination after passing our rigorous 8-step testing procedure. Because of this, every piece in bulk shipments has a consistent standard and output.

5. Dedicated Technical Support

At DMKE, we take customer assistance very seriously. You get everything you want from the moment you get in touch with us to the final product delivery, and even afterwards.

6. Long-Term Partnership Reliability

At DMKE, we provide more than just motors. We offer smooth and consistent repeated deliveries with reliable post-sales services. All such things make us a perfect long-term partner for those looking for a supplier they can trust.

| DMKE Capability | Customer Benefit |

| In-house R&D | Fast customization |

| Automated production | Lower unit cost |

| Strict QC | Quality consistency |

| Engineering team | Better system match |

4 Simple Steps to Your Custom Servo Solution With DMKE

At DMKE, we offer high-torque and customised servo solutions in a straightforward, transparent, and easy way. Our process is designed to eliminate all the guesswork and ensure that whatever technical requirements our customers have are met and delivered beyond perfectly.

Below are the four simple steps to follow if you want to get a custom servo motor made and delivered to you by DMKE.

Step 1: Requirement Communication

It is very important for us to have a clear understanding of your vision and what you have in mind.

For this, you need to not only specify the torque, voltage, and speed ranges of your motor, along with its encoder preferences and environmental considerations, but you will also have to tell us in detail regarding your expectations from that motor.

It is best if you could share existing drawings, layouts, and load calculations that you already have in mind to help our team provide a precise recommendation that meets and exceeds your expectations.

Step 2: Technical Confirmation

Once we have understood all your requirements and expectations from a servo motor, our team of engineers will review the details and look for any kinks or loopholes that need to be addressed.

After this, we will propose to you the most suitable motor configuration. Our proposals come with proper 3D and 2D drawings along with technical details and technical insights for our customers’ understanding.

This step usually takes time, but it is important. Our team at DMKE ensures that whatever we are recommending to our clients at this stage not only fulfils their wishes but is also operationally and functionally free of any constraints.

Step 3: Production and Quality Verification

Once the client approves the technical details of the motor and is ready to go ahead, DMKE starts its production process. For most orders, items are prepared in batches, and each and every unit undergoes a vigorous 8-step quality testing prior to its finalisation.

The eight steps that each of our units goes through include torque, accuracy, vibration, heat resistance, and durability checks. This makes sure that each and every piece that we produce will meet the same standards and will remain consistent in terms of its standards and output.

Step 4: Delivery and Long-Term Support

Once your bulk batch is ready, the final step focuses on smoothly delivering the product that we have made for you, along with ensuring regular communication. All our volume shipments are made according to agreed schedules with our clients.

DMKE’s team provides ongoing technical assistance, calibration advice, and guidance for the future as well. In short, when we sell you a motor, we are not just selling a product, but are also building a long-term relationship based on reliability and a partnership that goes beyond a single purchase.

Get Your Free Selection & Quote Now

Choosing the right kind of high-torque servo motor, especially when procuring in bulk, shouldn’t be complicated. It is something that we at DMKE understand. We will make sure to provide you with a product that matches in terms of its expectations and technical requirements.

All our engineers are experienced and adept at blending reliability with consistency across all our production lines so that you can get reliable motors for robotics, AGVs, or other heavy-duty industrial applications.

Our customers can reach out directly either through our website or through WhatsApp if they want to begin with their free consultation. We cater to each and every inquiry with expert guidance, detailed 2D and 3D designs, along with in-depth practical advice on the best motor configuration.

With us, there are no commitments, only clarity and support that help you make the right decision. Placing bulk orders with us can help you avail further benefits with guaranteed delivery schedules, reliable quality, and technical assistance that goes beyond specific timelines.

Take the next step today: get your personalised recommendation and consultation, verify specs with visual drawings, and get ready to bulk buy high-torque motors for all your system requirements with DMKE.