If you belong to the automation industry and work with AGVs or robotic systems, it is not uncommon for you to come across issues. Most of the time, everything looks great on paper, but once the manufacturing and mechanical processes are completed, the resulting system works totally differently from what is expected.

One might wonder what has caused this issue, especially when the structure looks stable. This mostly happens not because of the software or mechanical problems. Instead, it is because of a deeper underlying problem in the setup’s motor.

This explains why choosing the right motor is one of the major steps in the formation of any AGV or robotic line. The entire performance and practical application of a system depend entirely on how well it is motorized. In other words, the efficiency of an appliance is defined by how powerful its motion hardware is.

The right underlying motor is especially important for industrial environments where downtime is non-negotiable and precision is your only way to go. Now, more and more procurement and engineering teams are shifting towards brushless technology over any other version of motors.

This is because of the stability and predictability these motors offer and how they require less maintenance. In this article, we are going to cover the major advantages of using brushless motors in AGVs, robotics, and other automation lines that require precision and stability.

But before that, we are also going to touch on what a brushless motor is, and what are the core features any mechanical hardware for AGVs and robots must possess?

Understanding Brushless Motors in the Simplest Way

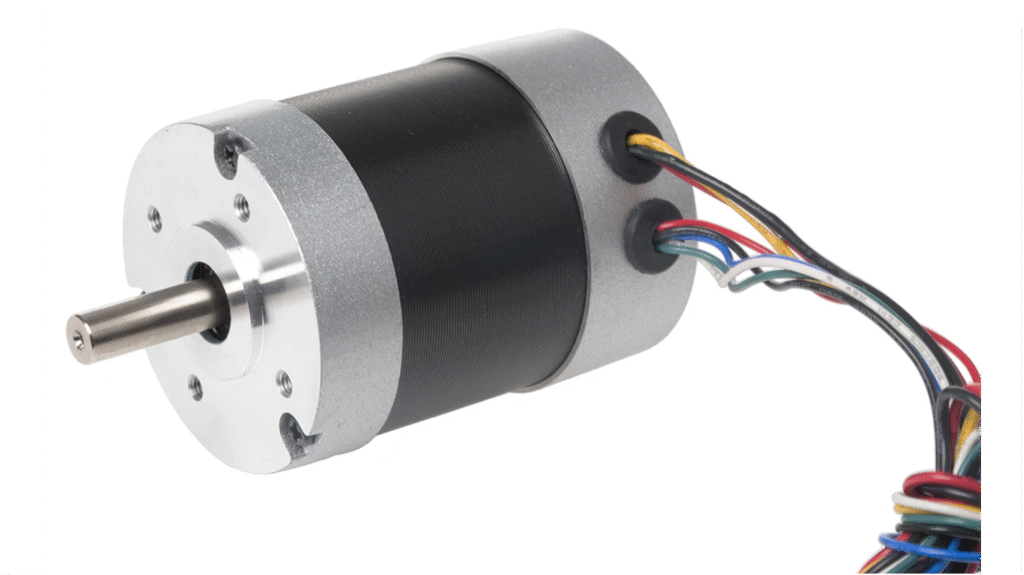

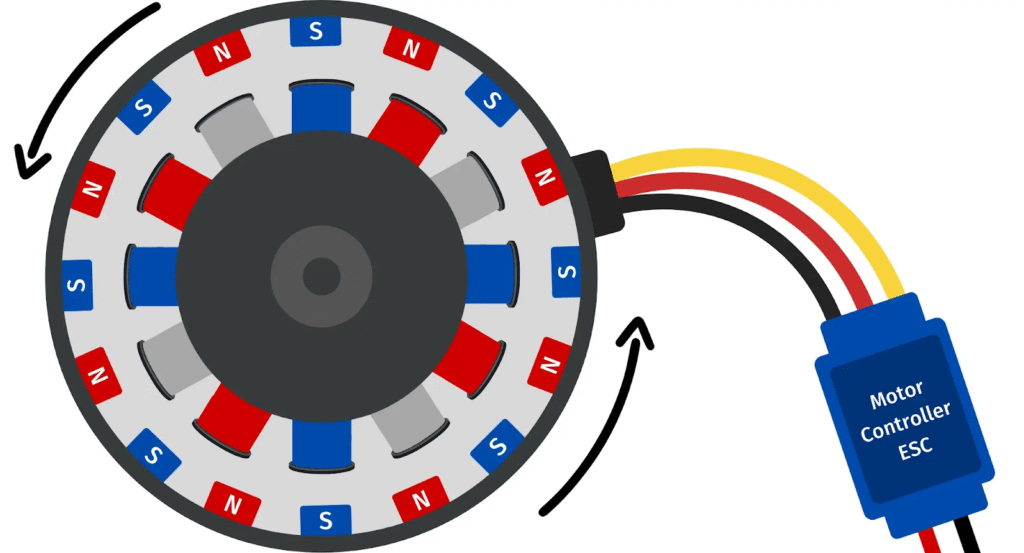

You might understand a brushless motor as something that comes with extremely complex engineering and technical layers. However, you’d be surprised to see how the idea behind a brushless or BLDC motor is extremely simple and basic.

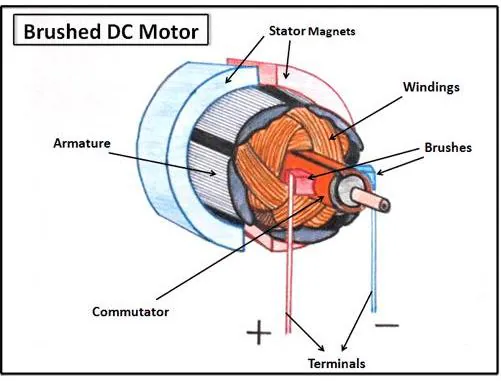

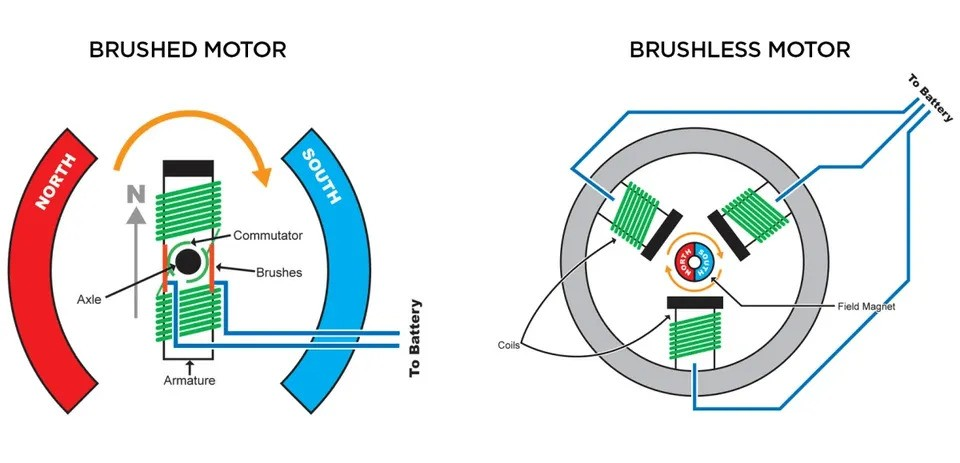

To understand what it exactly is, you can think of it as an enhanced version of the older brushed design. It removes all the weak points that a brushed design had. In short, there is less friction, fewer sparks, less heat generation, and almost no consistent wear and tear.

Simply, a brushless motor converts the electrical energy into mechanical energy inside it without relying on physical brushes. It instead uses electronics to perform this switching job precisely and in a more stable manner. This simple swap from mechanical touch to electronic control changes everything and makes this motor way better than older classical versions.

In a brushless assembly, the rotor spins while facing less resistance, and the mechanical response is smooth. Moreover, the energy fed into such a system turns almost accurately into a motional output. This means there is no loss of energy in the form of heat.

For mechanical devices that run AGVs and robots, long and non-stop running shifts are expected and very common. Many times, these devices have to face frequent stops or move through narrow pathways. All of this is demanded of them while they deal with a change in loads.

During all of this, the efficiency and smoothness of their motorized interior cannot be compromised. In other words, there is no other option for engineers but to run AGVs and robots on an efficient and electronically controlled setup. A brushless motor seamlessly comes with all of these features.

To sum up, a brushless mechanical core of any device is a smart and compact controller that electronically manages its motion. While doing so, it ensures little to no deviations in its working. It also requires minimal maintenance and performs almost quietly without being affected by heat. All of these features make it ideal for longer operating cycles.

What AGVs & Robots Need From a Motor

Regardless of their differences, all AGVs and robots have more or less similar expectations from their mechanical setup. In both these industries, predictability, stability, and long-lastingness are core requirements. Below, we are going to discuss a few things that all AGVs and robots need from the motor that runs them.

1- Consistent Torque Across Changing Loads

AGVs often have to carry different loads. Robots have to execute real-time movements while responding to changing directions and obstacles. All such actions require the internal motor housing of these appliances to hold a steady torque despite fluctuating external loads.

Unless this consistency and stability in torque are achieved, both the AGVs and robots can find it hard to properly navigate and often end up in accidents.

2- Efficient Operation In Longer Tenures

Whenever the motorized hardware of an appliance loses its energy in the form of heat, the overall working efficiency of the appliance decreases. You don’t want your AGVs’ runtime to slow down or your robots’ battery to die out after performing a simple task.

This is why both these equipment need to run on mechanical systems that last for longer shifts without interruption and have a nice battery life. This is where brushless motors come in handy. Thanks to their longer lifespan and reduced energy loss, AGVs and robots can enjoy minimal downtime.

3- Vibration-free and Quiet Motion

Both robots and AGVs often have to maneuver through tight and confined spaces. In such areas, jerks and vibrations of the appliance stand no chance. This is why their powerhouses have to ensure smooth and vibration-free control – something that only a brushless motor can provide.

4- Low Maintenance For Industries For Automation

In automated devices, downtime is often extremely damaging and smooth long-hour operation cannot be compromised on. In such devices, there is no room for frequent brush changes, recharge, or cleaning.

It is, therefore, perfect to construct them with systems that require low maintenance and can run seamlessly even with minimal attention and intervention.

5. Small Size, Compactness, And Portability

Modern automation is all about making portable devices that can fit into confined spaces. Such small devices, however, must never sacrifice their performance and efficiency. Therefore, these are built with motors having housings that deliver proper torque and speed without taking up a lot of room.

6. Precision And User-Friendly Controls

For AGVs and robots, the efficiency of navigation and precise positioning are extremely fundamental. Therefore, you need motors and lifting mechanisms that respond accurately and quickly to each and every command and changing situation.

If you look closely, you will see how all the above demands of the modern automation setups can be well fulfilled by a brushless motor. Below, we’re going to look into the top benefits of brushless systems. These will help you understand how these systems are ideal for modern robots and automatically guided vehicles.

The 5 Core Benefits Of Brushless Motors

Let us look at some of the major benefits of brushless motors that make them ideal for automation lines, AGVs, and robotic industries. Each of these benefits will also help you understand why BLDCs and other brushless motorized solutions are all the rage nowadays:

- Higher Energy Efficiency

When we speak of automated systems where precision is the core requirement, energy efficiency can not be defined in numbers or percentages. We don’t look at it as just a technical metric, too.

Rather, it is a direct representative of the longevity and operational time of the appliance. If an appliance is powered by a motor that wastes power, creates a lot of heat and needs more charging cycles, reduced productivity and downtime become common.

This loss of energy is not an issue with brushless systems. Here, most of the input energy is converted directly into motion rather than being lost in heat. As a result:

- AGV can cover longer routes before requiring another charge.

- Robots can complete more cycles per shift.

- The overall battery health of the devices remains stable over time.

In brushless systems, there is relatively little friction inside the motor housing. This can make the efficiency consistent regardless of how long the device keeps operating. This is what a brushed motor can never attain.

- Longer Lifespan With Minimal Maintenance

For AGV fleets and robotic systems, maintenance and downtime are one of the heaviest hidden costs that not everybody talks about. Even when machines are fully functional, even a single worn-out brush in their interior can cause a crash.

Brushless motors are free of such issues. There are no brushes that would grind, need replacement or cleaning, thus reducing the overall downtime.

In such systems, the internal components stay intact and last longer even when they are working in dusty or highly vibrational environments. This reduces their maintenance cycles and gives them a longer service life that makes them capable of 24/7 automation.

- Smooth, Precise, And Stable Motion

Automated systems cannot compromise on the stability, precision, and smoothness of their movement. This is something that a brushed motor can never achieve.

Brushless systems, on the other hand, excel in their electronic commutation, thus making the appliance feel like it is moving in a fluid manner with predictable acceleration and deceleration. For robots that perform repetitive tasks, the smoothness ensures accurate positioning and the safety of the operation.

- High Torque Density In A Compact Size

Speaking of AGVs and robots, there is rarely any extra space inside their assembly. Hence, engineers and architects must tightly fit the wiring, actuators, sensors, and batteries inside their compact bodies. Only brushless motors are capable of delivering strong torque to such small bodies, thanks to their internal magnetic design and efficient structure.

This high torque density is what lets small robots lift heavy equipment without any effort. It also allows the AGVs to move freely with a stronger pulling force. All brushless motors are made in such a way that their equipment remains lightweight and compact despite their strong abilities.

This portability, combined with power, often determines how perfect an automated system will be.

- Better Heat Management And Overall Reliability

In the case of modern AGVs and robots, continuous running is common. This often leads to the entire system heating up. This heat generation stresses the entire system, often resulting in downtime and failures. In case a brushless motor is not used, even the slightest increase in temperature can lead to slower performance, weaker torque, and failure.

However, brushless assemblies sort this problem out by effectively distributing heat through reduced internal friction. Such assemblies have better and improved coil structuring. In brushless setups, both the magnet and stator are made up of the highest quality material that is able to resist quick heat-ups.

When the internal assembly of any system remains cool despite an increasing load on it, the performance is maintained properly regardless of how long the appliance runs. This is one of the key requirements for logistics robots when AGVs work in logistics and production lines.

How to Choose the Right Brushless Motor for AGVs & Robots

Choosing the right brushless motor for your needs is not difficult. It simply begins with understanding how your AGV or robot will work and how it will behave during its entire working tenure. For each application, there will be a specific motion pattern, load, shifting, and limitations that you need to define in order to buy the right mechanical fit for it.

Once you have defined what you need, the first thing to look for in your options is torque. Most of the time, AGVs and robots have to experience sharp changes in their payloads along with ramps. This means a good motor for such applications should have a system that can easily handle peak torque without showing any signs of instability or heating up.

Another consideration should be the speed. After looking at torque, you should also look at the speed because some systems will need slowly working motors, while others will require steady motion. Some will prefer a quick response, while others are more concerned with how precise the response is. It’s best to choose a mechanical brushless motor with a speed range that aligns with your appliance’s requirements.

Another thing to look at is the space constraints. Most of the time, automated appliances are either compact or portable or have very little area to work around. For such appliances, a brushless motor with high torque density is ideal as it can ensure strong performance without consuming a lot of space.

However, when we speak of portability, thermal behavior cannot be ignored. A brushless motor with efficient heat distribution and dissipation will be the one that can easily operate while offering reliability and reduced downtime.

In battery-powered systems, efficiency is a core requirement and something that cannot be ignored. A motor that offers high efficiency directly enhances the overall working of the system, reducing the downtime and extending its runtime.

Lastly, you have to look at the compatibility, as a well-matched controller is the only thing that can help a brushless motor work properly and save it from downtimes.

Mistakes To Avoid In Brushless Motor Selection

Below are some mistakes that you should avoid at all costs when investing in a brushless motor:

- Only looking at the rated torque of a motor without considering its peak load conditions is a mistake you don’t want to commit.

- Never ignore thermal limits of the mechanical setup. If possible, also try to understand the housing and interiors to look at how well ventilated it is, as your ultimate goal is to manage heat accumulation.

- Going for a speed range of a motor that doesn’t match the real-world movement of the AGV or robot is a mistake, too.

- Never overlook the space required by the electric motor for fitting. This includes looking at how much space will be needed for wiring, drivers, and sensors.

- Getting an incompatible driver or controller for a high-quality mechanical device is another issue that many people often ignore.

- Ignoring battery efficiency for mobile AGV robots is another mistake.

- Taking a universal approach to each selection and not customizing your requirements as per your needs also ends up in chaos.

Get DMKE Brushless Motors – A Strong Fit for AGVs & Robots

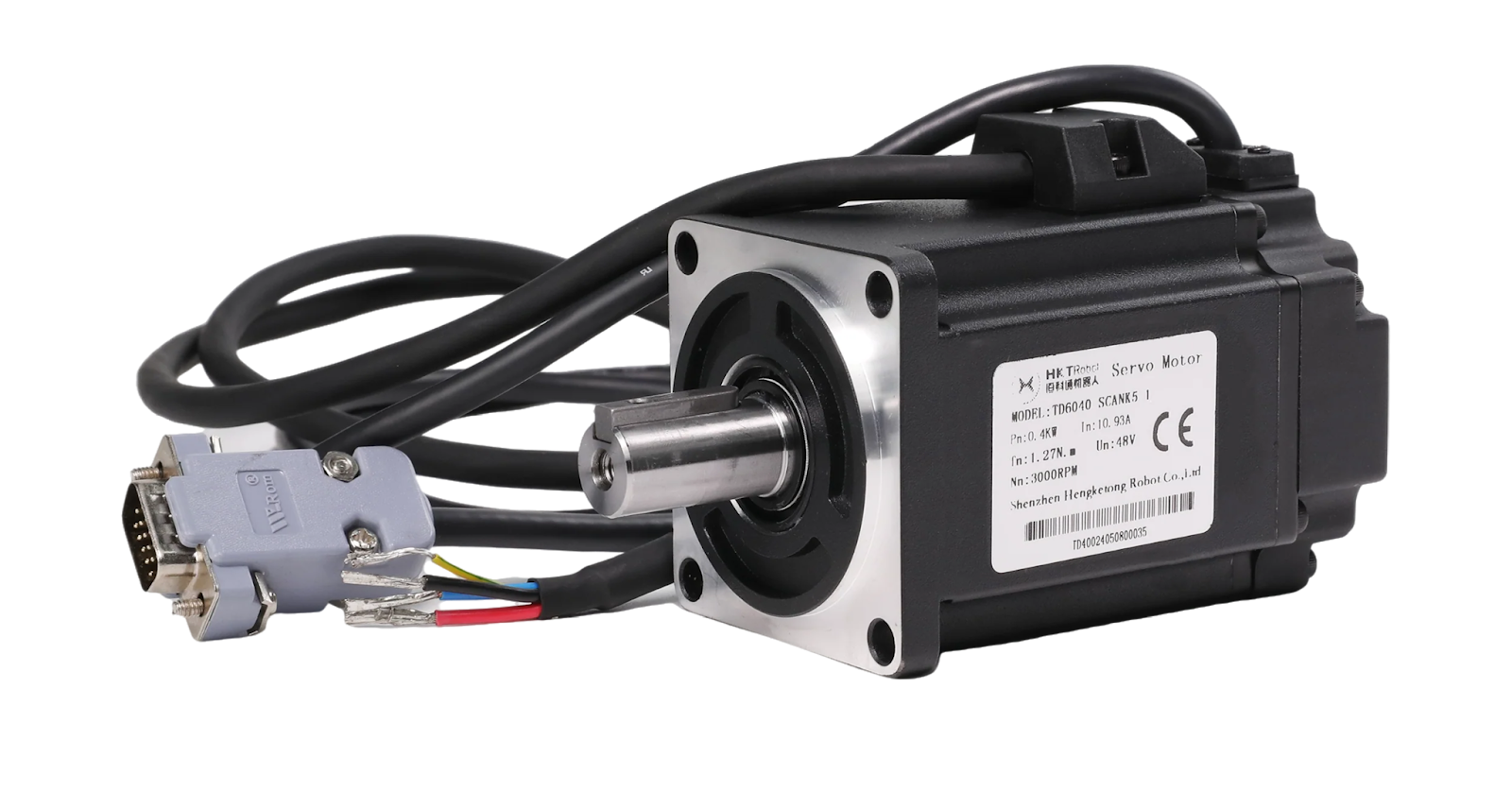

At DMKE, we have been making reliable AC, DC, BLDC, and Servo solutions for the fast-paced automation world for many years. Many of our high-performance offerings have been empowering AGVs and robots throughout the world in a precise, reliable, and long-lasting manner.

All of DMKE’s brushless motors are engineered with high-quality components and are meant to meet the exact specifications of the appliance they are made for. Prior to their release and sale, each of our units undergoes a smooth and rigorous 8-step verification process to ensure its quality and seamlessness.

Whether you go for ready-made solutions or connect with experts at DMKE for custom brushless motors, each of our solutions will provide you with solutions that minimize maintenance needs and offer strong performance. Each unit that we sell comes with strong after-sales support, giving you peace of mind and confidence in all your purchases.

Visit our website to contact us or send us a WhatsApp message so we can begin discussions on optimizing your AGVs and robotic solutions in the best way today.