Connecting a motor to a power source might seem straightforward at first glance, but it is a task that many beginners and even experienced people approach with caution.

Mistakes like reversing connections, using the wrong wires, or overloading can lead to damage to the machine, the power supply, or even create safety hazards such as sparks or overheating.

The challenge often comes down to understanding the motor itself and source of power you plan to use. Motors are available in different shapes, sizes, and types, each with specific voltage and current requirements. Even small mismatches can reduce efficiency, shorten the lifespan, or, in worst-case scenarios, cause a fire. Knowing these basics before starting can save a lot of investment, time, and – most importantly – frustration.

Another factor to consider is safety preparation. Simple steps like using insulated tools, checking wire connections, and confirming voltage compatibility can drastically reduce risks. Yet, many people skip these steps because the process seems complicated or intimidating. Knowing the “why” behind each step makes the flow more approachable and less prone to errors.

This guide is designed for anyone who wants a clear, step-by-step understanding of how to connect motor to power source safely. Whether you are working on a DIY project at home or setting up a small automation system, the tips and explanations here will help you make better decisions, prevent common mistakes, and approach the task with confidence.

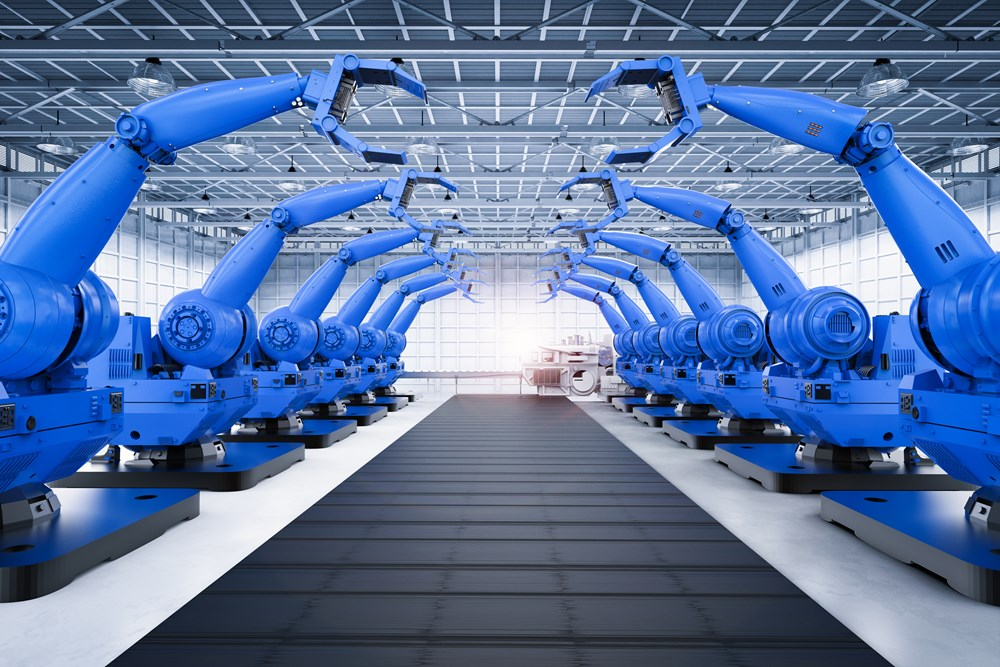

Understand Your Motor and Power Source

Alt Text: Motor being used

Before you connect it to a power source, it is important to understand the motor you are working with. It may look simple from the outside, but the internal design determines how they perform and what kind of power they need. Using a wrong machine or pairing it with an incompatible power source can result in poor performance, shortened lifespan, or even safety problems like overheating or electrical fires.

Types of motors

Two types are most commonly utilized in industrial applications: brushless DC ones and brushless servos. Brushless DC motors are popular because they are efficient, quiet, and long-lasting. They are used in drones, small robots, and electric vehicles. Since they do not have brushes, there is less friction, which means smoother operation and less maintenance.

Brushless servo motors, on the other hand, are designed for precision. They are commonly found in robotics, CNC machines, and automation systems where accurate positioning is crucial. While a brushless DC motor prioritizes speed and efficiency, a servo puts an emphasis on accuracy. Understanding the differences between these types helps you choose the right one for your project before connecting it to a power source.

Voltage and current: why they matter

Voltage and current are two important factors to take into account. Voltage is the amount of electrical potential your engine requires, while current is the amount of power it draws during working operation. Using a motor with a power source that does not match its voltage rating can prevent it from starting or cause overheating. Similarly, getting too much current can damage the machine or the power supply.

Matching motor and power source

It is also important to consider the load requirements. Motors draw more current when under heavy usage, which can put pressure on your power supply if it is not rated for peak conditions. Checking the datasheet or specifications before connecting it ensures compatibility and prevents unseen issues. Understanding the relationship between the type, voltage, current, and load sets a solid foundation for a safe and effective setup.

By taking the time to understand your power engine and power source, you avoid common mistakes and reduce risks. Knowing these basics makes the next steps of wiring, testing, and operation much smoother and more reliable.

Tools and Safety Gear You Need

Alt Text: Safety should always come first

Knowing how to connect motor to power source also means having the right tools and preventive gear. Even if you understand your power engine and power supply perfectly, skipping basic safety precautions can lead to mistakes, equipment damage, or injuries. Taking a few minutes to prepare your workspace and gather the right equipment makes the process much smoother and safer.

Essential tools

The first step is to make sure you have the right tools on hand. A multimeter can help you confirm that your power supply matches your machine’s requirements.

Insulated wire cutters and strippers make it easy to prepare your wires without risking accidental shocks. Screwdrivers and wrenches are often needed to secure terminals and mount the machine properly.

For permanent or semi-permanent connections, a soldering iron can be useful, though connectors like banana plugs or crimp terminals are excellent alternatives for less permanent setups.

Safety gear

Insulated gloves protect your hands when handling wires under power. Safety goggles shield your eyes from sparks or debris during wiring or soldering. Anti-static mats help prevent static electricity from damaging sensitive components, especially for brushless DC or servos.

Preparing your workspace

A well-organized workspace reduces mistakes and makes connections safer. Keep wires untangled and components within reach. Make sure your work surface is dry and free of junk. Double-check that the power supply is turned off before making any connections.

By taking the time to gather the right tools and safety equipment, you are setting yourself up for a smooth and safe process. Understanding how to connect motor to power source is not just about wiring; it is about creating a setup that reduces risk and increases success.

Step-by-Step Guide: How to Connect Motor to Power Source

Alt Text: Step by step guide on how to connect motor to power source

Connecting a motor to a power source can feel intimidating at first, but with the right approach, it becomes a manageable and even enjoyable task. This guide breaks the process down into simple steps, making it accessible whether you are working on a small DIY project or a more advanced setup. Each step focuses on safety, clarity, and ensuring it performs as expected.

Step 1: Identity motor terminals

Before doing anything, take a close look. Most of them have clearly marked terminals. For simple DC motors, you will usually see a positive (+) and a negative (-) terminal. Brushless, such as brushless DC (BLDC) or brushless servo motors, often have three wires, sometimes color-coded, which represent the different phases needed for the motor to run smoothly.

It is important to check the datasheet or user manual. This document will show the correct wiring, recommended voltage, and current limits. Checking the datasheet may seem like a small step, but it is the foundation of a safe and successful connection. For example, DMKE provides extensive information for all of the brushless ones it has, which can help you identify terminals and understand its capabilities.

Take a moment to inspect your wires and terminals for any damage. Frayed wires or loose connections can lead to shorts, overheating, or even permanent damage. Ensuring everything is firm before you connect power is an essential safety step.

Step 2: Inspect your power source

Not all power supplies are created equal, and picking the wrong one can cause frustration or worse. Start by checking the voltage and current of your power source. Make sure it matches the specifications of your motor. For example, if it is rated for 24 V, but your power supply provides 36 V, connecting them directly could burn out the motor in seconds.

Polarity is another important factor. Double-check which terminal of the power supply is positive and which is negative. Reversing polarity can prevent the motor from running or cause permanent damage. For brushless ones, phase order matters as well. Incorrect wiring of the three-phase wires may cause it to spin in the wrong direction or operate inefficiently.

Using a regulated power supply is strongly recommended. A regulated supply ensures that voltage and current remain stable during operation. Unregulated supplies can change under load, which could stress the motor and shorten its lifespan.

Step 3: Wiring the motor

With the motor and power supply inspected, it is time to make the connection. Start by stripping the ends of your wires carefully. Exposed copper should be just enough to fit securely into the terminal or connector without leaving loose strands.

For simple DC options, connect the positive wire from your power supply to the motor’s positive terminal and the negative wire to the negative terminal. For brushless ones, connect the three phase wires according to the datasheet. Many BLDC motors use a color code but always confirm with the manufacturer’s documentation.

Once the wires are connected, secure them. Loose wires can lead to arcing or poor contact, which may damage the motor or power supply. Use screws, terminal clamps, or crimp connectors to ensure a tight fit. Avoid forcing wires into terminals; if it does not fit easily, double-check the wire gauge and terminal size.

Step 4: Using connectors vs soldering

You have a choice when connecting wires: connectors or soldering. Each has advantages depending on your needs.

Connectors, such as crimp terminals or banana plugs, are quick to install and allow easy disconnection for maintenance or upgrades. They are ideal for projects where motors may be swapped or adjusted frequently. Soldering, on the other hand, creates a permanent, highly reliable connection. It is better for applications where the motor will stay in place for long-term use and stability is critical.

For brushless motors, using high-quality connectors or soldered joints is particularly important. Poor connections can lead to uneven current flow, which may reduce efficiency or create excessive heat. Take your time to ensure every connection is solid and secure.

Step 5: Testing the connection safely

Before applying full power, it is essential to test the connection safely. Start with a low-voltage test. If your motor operates at 24 volts, begin with 12 volts or use a current-limited power supply. This allows you to check that it runs in the correct direction and that there are no sparks, unusual noises, or overheating.

A multimeter is a valuable tool in this step. Use it to confirm that voltage at the terminals matches the motor’s specifications and to measure the current draw. Any significant deviation may indicate a wiring issue or a problem with the motor.

If the motor does not run as expected, double-check terminal connections, polarity, and phase order. Reversing two phase wires on a brushless motor can reverse its direction. Small mistakes are common, and taking the time to troubleshoot at low voltage prevents damage later.

Step 6: Final checks and operation

Once your motor runs correctly at low voltage, it is time for the final checks. Ensure all wiring is tight, insulated where necessary, and away from moving parts. Check that motor mounts are secure and that it is aligned properly in its intended position.

Gradually apply full power while monitoring the motor for unusual sounds, vibration, or excessive heat. Pay attention to torque limits specified by the motor manufacturer. Exceeding these limits can stress the motor and reduce its lifespan.

Even after everything is connected and running smoothly, periodic checks are important. Inspect wires and connectors regularly and make sure that heat buildup is minimal. Consistent maintenance keeps the motor performing reliably and reduces risks.

Step 7: Why quality motors matter

Using a high-quality motor, like those from DMKE, simplifies the process and reduces the chance of mistakes. Clear terminal markings, detailed datasheets, and robust construction make it easier to connect your motor with safety. With predictable performance and built-in reliability, you can focus on your project instead of worrying about wiring errors or early motor failure.

By following these steps carefully, you can confidently connect a motor to a power source, whether it is a simple DC motor for a hobby project or a brushless servo motor in a more complex automation setup. Taking your time, testing carefully, and utilizing quality components are essential to a successful and safe motor connection.

Common Mistakes to Avoid

Alt Text: Mistakes to avoid

Even when you understand your motor and power source, mistakes can still happen. Avoiding these common errors is key to keeping your motor, power supply, and workspace safe. Below are some of the most frequent mistakes people make when learning how to connect motor to power source.

Reversing polarity

One of the simplest mistakes is connecting the positive wire to the negative terminal or vice versa. For a DC brushed motor, reversing the positive and negative terminals will cause the motor to rotate in the opposite direction; however, for a brushless DC motor, if the polarity is reversed, the driver will be damaged and the system will cease to function properly.

Imagine you are building a small conveyor belt system for a school project. You connect your motor backwards, and instead of moving objects forward, the belt runs in reverse. A quick check of the terminal markings or a datasheet can prevent this problem.

Using undersized wires

Another common issue is using wires that are too thin for the current your motor draws. Thin wires can overheat, melt insulation, or even start a fire in extreme cases. For example, if you are powering a 24-volt brushless motor that draws 5 amps at peak load with a wire designed for only 2 amps, the wire will heat up and could fail. Always choose wire gauges that match or exceed the motor’s rated current.

Skipping fuses

Fuses may seem unnecessary in a small project, but they are a crucial safety feature. They protect both your motor and power supply in case of a short circuit or overload. Suppose you are testing a new robot arm and skip adding a fuse. If it accidentally stalls or a wire shorts, the entire power supply could be damaged. Adding a correctly rated fuse is a simple step that can save expensive components.

Ignoring datasheets

Many beginners tend to skip reading the motor datasheet, assuming the wiring process is straightforward. However, the datasheet contains critical information such as voltage, current ratings, recommended wiring configurations, and load limits. Neglecting this step may lead to errors, including incorrect voltage connections or exceeding the motor’s torque limitations.

For brushless DC motors, power is not connected directly to the motor but to the driver. The battery must supply power to the driver at a voltage that matches the motor’s rated voltage. For instance, if the motor is rated for 24V but is supplied with 36V, the motor will run at approximately 1.5 times its designed speed. This can result in excessive rotational speed, overheating, and even motor burnout.

Being aware of these mistakes and taking preventive steps makes the process of connecting a motor to a power source much safer. Careful preparation, proper wiring, and attention to manufacturer guidelines will save time, money, and headaches.

Maintenance Tips for Safe Operation

Alt Text: Maintenance tips

Connecting a motor to a power source is only part of the process. Regular maintenance ensures that your motor continues to run smoothly and safely over time. Even a well-installed motor can experience wear or issues if small maintenance steps are overlooked.

Check connections regularly

Loose or corroded connections are one of the most common causes of motor problems. Periodically inspect all wires, terminals, and connectors. Make sure screws are tight and there are no exposed wires. A simple visual inspection can prevent unexpected failures and ensure your machine continues to operate as intended.

Avoid overheating

Motors generate heat during operation, and excessive temperatures can shorten their lifespan. Keep an eye on it while it is running, especially during heavy use. If it feels unusually hot, turn it off and investigate. Overheating can often be caused by incorrect voltage, excessive load, or blocked ventilation.

Keep terminals clean

Dust, dirt, and moisture can interfere with electrical connections. Gently clean terminals with a soft cloth and ensure there is no corrosion. Clean terminals improve conductivity, reduce resistance, and prevent potential short circuits.

Lubricate moving parts

Some motors require occasional lubrication to reduce friction and wear. Check the manufacturer’s guidelines before applying oil or grease. Even a small amount can improve efficiency and extend the motor’s lifespan.

By performing these simple maintenance steps, you protect your investment and keep your motor running safely. Proper care not only prevents problems but also ensures consistent performance every time you connect a motor to a power source.

Why Choosing the Right Motor Supplier Matters

Alt Text: Choosing the right supplier is important

Choosing the right motor supplier is more than just picking a product. The quality, reliability, and support you get from your supplier can make a big difference in how easily and safely you connect a motor to a power source. High-quality machines reduce the chance of wiring mistakes, prevent premature wear, and improve overall performance. They also give you peace of mind that your project will run smoothly.

One of the main advantages of a reputable supplier like DMKE is access to accurate documentation. Detailed datasheets, wiring diagrams, and technical specifications help you understand the motor before you even touch it. This guidance can prevent common mistakes, such as connecting the wrong voltage or using incompatible connectors. Having this information at your fingertips makes the setup process faster, safer, and less stressful.

Reliable suppliers like DMKE also provide support. Whether you have a question about wiring a motor or troubleshooting an issue, responsive technical assistance can save hours of trial and error. In addition, quality suppliers often offer a wide selection, from simple brushless DC motors to precision brushless servo motors. This allows you to choose the right one for your project without compromising on safety or performance.

For anyone learning how to connect a motor to a power source or working on a critical project, starting with a high-quality motor from a trusted supplier can make the difference between a smooth installation and a frustrating experience. A supplier that combines reliable products, clear documentation, and responsive support sets you up for success, ensuring your motor performs safely and efficiently from the very first connection.

FAQs

Can I connect multiple motors to one power source?

That is correct. However, it is essential to ensure that your power supply can meet the combined voltage and current requirements of all the motors. If the battery cannot deliver sufficient current to support the total demand of multiple motors operating simultaneously, the motors will not be able to operate at their full potential.

What happens if I reverse polarity?

For a DC brushed motor, reversing the polarity will cause the motor to rotate in the opposite direction. In contrast, for a brushless DC motor, reversing the positive and negative connections will damage the driver and consequently render the motor inoperable.

How do I know if my motor is compatible with my power supply?

Firstly, verify that the power supply voltage matches the motor’s rated voltage, typically within a tolerance of ±10%. Secondly, confirm that the battery can deliver a current output at least 1.5 to 2 times the motor’s rated current, as the starting current generally exceeds the rated operating current.

Conclusion

Learning how to connect a motor to a power source safely becomes much easier when you break the process into simple, practical steps. From identifying the right choice to preparing your workspace and securing each connection, every part of the process contributes to smooth and reliable operation. Once you understand the basics, the task feels far less overwhelming and much more manageable.

Long-term care matters just as much as proper installation. Regular checkups, cleaning terminals, watching for overheating, and keeping an eye on performance all help protect your equipment. These small habits go a long way in preventing downtime and keeping your machine running the way it should.

One final piece of the puzzle is choosing a dependable supplier. Quality motors with accurate documentation make wiring safer, faster, and more predictable. This is why many builders and businesses prefer working with suppliers that combine reliable engineering with clear support.

If you ever need a motor that is easy to set up, built for long-term use, and supported by people who understand real-world applications, exploring a trusted manufacturer like DMKE can be a smart place to start. They offer a wide selection of brushless DC and brushless servo motors designed for safe and efficient integration into various projects.

With the right preparation, the right choice, and the right support, connecting a motor to a power source becomes not just doable but pleasantly straightforward.