Working with a BLDC motor can be extremely rewarding, thanks to its seamless and powerful performance with minimal lag. However, it is not unusual for engineers to come across BLDCs that overheat, vibrate, lose their torque, and simply trip under changing loads.

Facing such a situation in an industrial environment is not only disturbing but also results in non-negotiable costs in lieu of downtimes. However, many times the problem is not with the motor itself, but rather its control drive system.

Many people commit the grave mistake of not investing in a suitable BLDC motor controller. For them, the role of a control driver is not as important as that of a motor. Unfortunately, this is the wrong approach to motor purchase and installation.

Investing in a random control solution will have you end up with mismatch voltages, improper acceleration, unreliable protection, and premature failures. All these issues not only affect the performance of the motor but also lead to inconsistent output with higher maintenance costs in industrial environments.

A controller is the brain and the heart of the entire motor system. It is the sole decision maker behind how your motor will behave, how smoothly it will start, how properly it will carry out the task at hand, and how efficiently it will deliver the torque. It also helps the motor accurately hold its acceleration while protecting itself from electrical faults.

Having the right kind of solution becomes even more important in industrial applications and AGVs, electronic bikes, conveyor belts, pumps, fans, robotic arms, and other medical equipment, where stability and precision cannot be compromised.

All of this explains why choosing the right one for your BLDCs is more than just a technical decision. It is a move that defines the benefit level or usability of your entire motor purchase. A good driver is the perfect investment for anybody who doesn’t want to make a compromise on the long-term efficiency and smoothness of their system.

There are a few essential tips that one must remember to avoid a poorly chosen control system. In this guide, we are going to uncover each of these tips one by one. Don’t worry, we are going to keep it simple, so by the end of this article, you can choose the right solution with confidence.

Before You Begin: What a BLDC Motor Controller Actually Does?

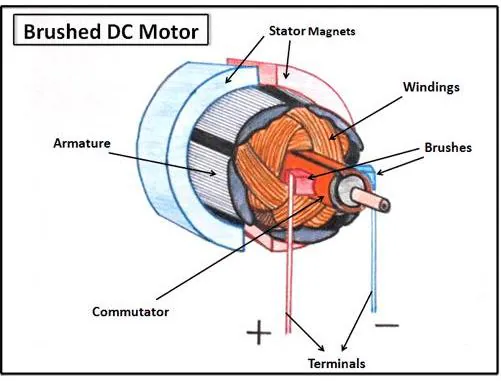

Before we begin to give you tips on how to choose the right kind of controller, it is important that you understand the controller in its deepest sense. While on the surface, a motor looks like it’s doing the entire job of handling the BLDC system, it’s actually the controller inside it that’s doing everything.

You can think of any motor’s driver as its command center or brain that decides how the entire system should work. It monitors the movements at every instant, sends precise electrical signals to the winding, and manages rotation along with every other part of the motor.

It manages how fast it should spin and how smooth and precise each action should be. It also receives the feedback on the motors’ functionality coming back from the encoder and makes real-time corrections to adjust everything.

Simply stated, the controller is responsible for the very first stage of your motor’s functioning, that is, converting the input into a command, to the very end, that is, ensuring a predictable and smooth motion for as long as possible.

Without the right controller, no matter how high-quality your motor is, it won’t work. An incompatible one will lead even the best motor to hesitate during starting, trip during acceleration, and produce jerky motion when the load on it changes.

Another important role of a good controller is the overall protection and safety of the motor. The right kind of controller will prevent the motor from overheating, shutting down under sudden load shifts, or getting damaged due to voltage imbalances by managing all of these issues before time. This makes it important for automated systems, where ignorance of precision can cause chaos in the whole setup.

Now that you have understood the basics properly, you must be clear on one thing: A controller is not just a motor accessory that you can buy with no proper consideration to its performance. Rather, it is what determines how the motor will perform and hence must be purchased with immense care.

Basic Tips To Choose The Right Controller

To choose the best controller, you have to first start shortlisting the promising options. However, even to make this shortlisted selection, you need to be aware of the core factors that influence the performance of any BLDC controller. Below are a few simple tips that you can use as your checklist while selecting any controller to ensure that you don’t end up with the wrong one.

- Match Controller Voltage & Current With Your BLDC Motor

This is one of the most important and yet the most ignored tip. Making sure that the voltage and current ratings of the controller match your BLDC’s current and voltage ratings is very important.

A controller and motor that are not aligned in terms of voltage are always struggling together, resulting in incompatibility issues. These include weak startup, poor torque, precision issues, overheating, irregular speed and tripping, and complete and quick system failures.

The first thing you must start with is voltage. Your controller’s voltage must match the system’s rated voltage, as it will ensure smooth activation and acceleration, along with stable torque and smooth braking. If the voltage is lower than the required voltage, the appliance will hardly ever reach its desired performance.

On the other hand, if the voltage is higher, the motor will give unpredictable performance and heat up, or completely damage itself right after starting.

The current ratings must also be considered. When you look at current ratings in controllers, you will see two values. The first one will be the continuous current that shows how much it can handle over longer work periods.

The second one will be the peak current that refers to the short burst capacity of the controller during startup acceleration or sudden load shifts. If the continuous current is way too low, the controller will overheat. Similarly, if the peak current rating is not high enough, the motor will stall and struggle when presented with sudden high loads or required quick accelerations.

A simple rule is to choose a device that comes with 10 to 20 percent higher current capacity than what your motor requires. This gives you a margin to be safe in applications where the load can suddenly vary.

Getting this basic step right is your first step towards the right and compatible controller for your motor. And if you succeed at finding a controller with current and voltage ratings that go hand in hand with your motor, you can easily ensure the long life and stability of your entire setup.

- Check Management Methods & Feedback Requirement

Depending on its application, each BLDC is required to have a specific level of control. A controller must support the motor in this regard. This is what makes all the difference between a hall sensor and a sensorless control in a motor system.

Hall sensor controllers come with built-in sensors inside the motor that help the motor read the rotor’s position. This reading lets it provide a smoother startup, better torque at lower speeds, and more precise speed control. This makes such motors ideal for AGVs, bikes, robots, medical equipment, and other automation lines.

Hall sensorless controllers, on the other hand, simply estimate the rotor’s position without any sensors. They are simple, cheap, and work well at medium to high speeds. However, they are not suitable for motors that have to perform extremely precise functions.

Once you have checked what kind of device you need, you have to consider the feedback needs of the motor. Some controls to consider are as under:

- If you want a motor that maintains consistent RPM, it must have speed control.

- For machines that have to handle variable loads, the motor must have torque control.

- Position control is required in robotics, conveyors, and automation packaging lines.

Depending upon the application for which you are purchasing the motor system, you also need to see whether you need a closed-loop controller or an open-loop one. All in all, matching all these control methods and feedback requirements to your controller helps you purchase the right item that performs exactly how you want it to.

- Look for Protection Features That Extend Motor Life

The difference between a good controller and a bad controller mostly lies in the protection features that it has. If a controller is able to offer abilities with which it can handle fluctuating loads, spikes in voltages, and overheating, the systems can stay stable.

Some important protection features to look for in a controller include the following:

- Over-current protection

- Over-voltage protection

- Overheating protection

- Short-circuit protection

- Stall protection

Unless a controller has at least three of these protections, the motor is destined to overheat, burn out, and leading to the collapse and failure of the entire system.

- Ensure the Controller Supports Your Required Speed & Load Profile

For each motor application, there is a specific operating pattern that the controller must be capable of handling. You can ensure its capabilities for your specific requirements by understanding the duty cycle of your system.

Depending on how long they have to run, there are continuous duty systems and intermittent duty systems. For example, fans, conveyor belts, and other systems that have to run consistently for long hours come under the continuous duty cycles.

On the other hand, intermittent duty cycles are commonly found in systems like robotic arms and frameworks that have to work with brake intervals. Getting a controller built for intermittent duty and forcing it to work continuously often results in overheating and failure of the system.

Once you get a driver that complements the duty cycle it is meant to be used for, you have to consider the speed range. For this, you have to ask yourself if your application requires slow or precise movement or simply wants high acceleration without much focus on precision. If you need higher acceleration and a wide RPM range, the controller must be able to support these without losing its torque, vibrating, or stalling.

Lastly, you need to check the load profile of the system. Check whether this entire application has heavy startup loads, gravitational resistances or inclines, or requires sudden reversals. A reliable controller should have the ability to comfortably operate with all types of load profiles. In other words, you should look for performance headroom when resting in a controller.

- Check Build Quality, Certification & After-Sales Support

Many BLDC motor controllers might look similar from the outside. However, it is the quality of their interior build that makes all the difference. Firstly, to ensure good build quality, you need to look whether it comes with physical features for strong heat dissipation. These mostly include aluminum housings, fins, and airflow design.

You also have to look for high-quality components that ensure long-lastingness and better stability of the entire system. Lastly, the drive solution and internal parts of the motor must be properly connected with each other with no intermittent faults.

Once you are sure of the build quality, you can ask the supplier for certifications like CE and ROHS. These prove the quality of the motor and reflect that it meets the safety standards set by any reputable authority.

Lastly, you need to see if your relationship with the supplier goes beyond just the sale and purchase. A reliable supplier will always offer some sort of guarantee and proper after-sales support. This reflects their confidence in the product they are selling while also making sure you are not left with guesswork during installation.

Additional Small Tips to Make a Better Choice

Other than these five main tips, there are a few other factors you can consider to ensure a seamless selection and better motor control. These might not seem very important at first, but once you choose a controlling device while considering these points, you’ll see for yourself the value of these secondary tips, too. So, read on:

- Firstly, it is important to invest in a solution that comes with a detailed visual manual and a user guide. Such booklets help ensure a seamless installation without any issues with the wiring and labels.

Having a user manual with properly-marked terminals and wiring guidelines saves time and eases the overall installation and initial understanding. Such manuals are almost non-negotiable when you need to set up multiple motors altogether and can’t take any risks.

- It is also important to go for controllers that allow for adjustments in their basic parameters and offer flexibility of tuning. Sometimes, even the smallest adjustments like soft-starting, controlling brake intensity, tuning acceleration slope, or the ability to change current limits can help improve the overall system’s performance to a measurable extent.

These adjustable and tunable parameters can help you customize the overall system as per your needs. Tuning also helps ensure that the system can respond to changing outer conditions and increasing loads seamlessly.

- Always go for a solution that matches your system’s communication modules perfectly. This is especially important for systems and applications where heavy integration is required.

Most of the modern systems now rely on external control signs like PMW, RS-485, or CAN bus. Choosing an incompatible controller often limits the overall functionality and halts the system.

- It is also important to look for controllers that offer heat dissipation through the mounting design. When controllers are present in tight and confined BLDCs, heat can build up quickly. A design with mounting holes or heat sinks helps ensure proper airflow.

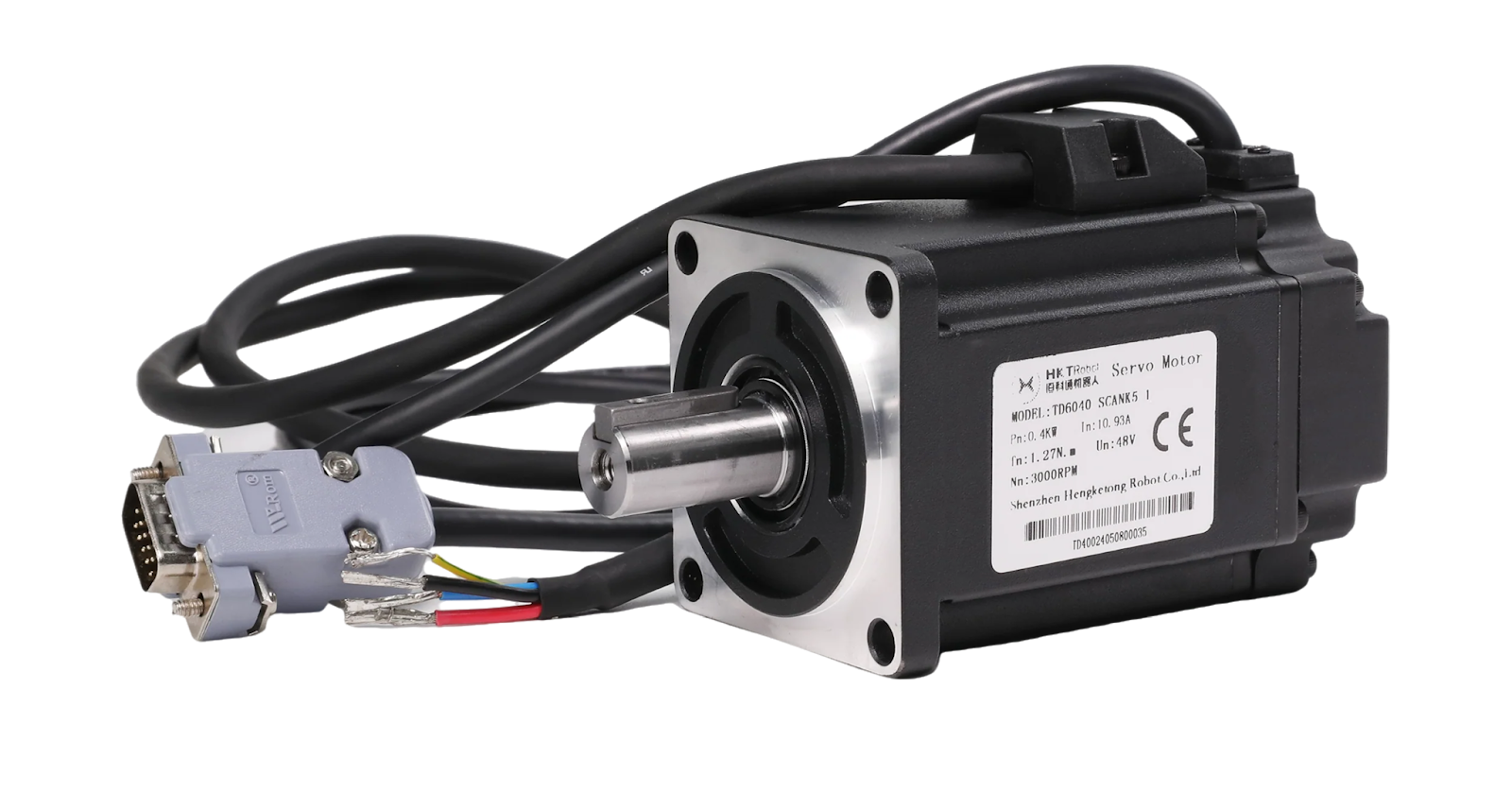

Contact DMKE for the Right BLDC Motor Solutions

Choosing the right BLDC motor controller is not just about finding something that matches your required specs. Rather, it is also about achieving long-term and smooth motor working along with stability and peace of mind.

At DMKE, you can get all of these along with our highest quality control solutions and motor sets that suit all your operational needs. Whether you want a ready-made BLDC and control system or are looking for custom-built motor or control solutions, we have it all.

From helping you choose the right kind of controller to customizing things as per your needs, our experts at DMKE are capable of doing much more than you can think.

Visit our website or connect with us on WhatsApp to get started and get your hands on the best BLDC motor controllers designed for industrial and real-world usages.

All our reliable solutions undergo 8-step testing before being made available for sale. Each purchase that you make with us is backed by expert post-sale service that vouches for our quality and trust in our offerings!