When we talk about motion control and automation in industrial applications, the word motor is something that is very common to come across. However, this term is often used broadly and in a generalized manner, with many not being aware of what exactly a motor does in a specific context.

For engineers and industry owners, however, the situation is a bit different. They can’t use this term broadly and instead have to differentiate between a common, generic, conventional electric motor and a servo or any other form of specialized device. Understanding servo vs motor in a generalized context is extremely important, especially when we speak about automation and industrial applications. This is because the servo is probably one of the most used motors across different industries.

Choosing between a servo or a generic conventional motor is not just a matter of finding the one with a better power rating or speed. Rather, this is a decision that directly affects the overall precision, responsiveness, energy efficiency, and control capability of a system that runs on that motor. Misunderstandings in basic motor distinction can lead one to invest in systems that underperform, have higher operating costs, and have design limitations that disrupt the overall efficiency and mostly become evident post-deployment.

Servo refers to a solution that is integrated into a closed-loop control system. Here, this motor continuously monitors and adjusts its own position, speed, torque, and overall working through consistent feedback via encoders and resolvers. A conventional or generic electric motor, on the other hand, operates primarily in an open-loop manner. This means that such a motor delivers continuous rotation when power is applied without having any knowledge of its working in real time.

While both these motors have an essential role in overall commercial and industrial applications, there are cases where one of these is more suitable than the other. This suitability is heavily determined by the level of control accuracy and adaptability that the system requires.

As automation systems evolve, along with the increase in their performance demands, the decision of choosing between servo vs motor in a conventional sense is becoming more and more strategic rather than a matter of personal choice. Servos are increasingly favoured in applications where high precision, fast dynamic response, and repeatability are required, while conventional and generic electric motors continue to dominate in applications where simplicity, robustness, and cost efficiency are major concerns for owners.

Below, we are going to provide you with a structured servo vs motor comparison. Our comparison will focus on control, performance, and real-world behaviour of the two, while also touching upon concepts like system complexity, application suitability, and more.

It is important to understand that, rather than positioning one as a better option than the other in a universal manner, it is your specific use case and requirement from a motorised setup that determines the right kind of device for your needs and the one that provides you the greatest value.

However, our in-depth guide will clarify the differences between both technologies, thus being a helpful read for engineers, designers, and other decision-makers who want to make informed choices aligned with real-world operational expectations.

Key Differences Between Servo Vs Motor

To understand the fundamental differences between servos and conventional electric motorized systems, one needs to look beyond basic specifications such as speed or power ratings. The real difference in both these systems lies in how they control motion, monitor their performance, and adapt to change in real-world situations.

The following comparisons highlight specific features and aspects of both these systems that help differentiate their approaches in real-world applications.

- Control Method: Closed Versus Open Loop

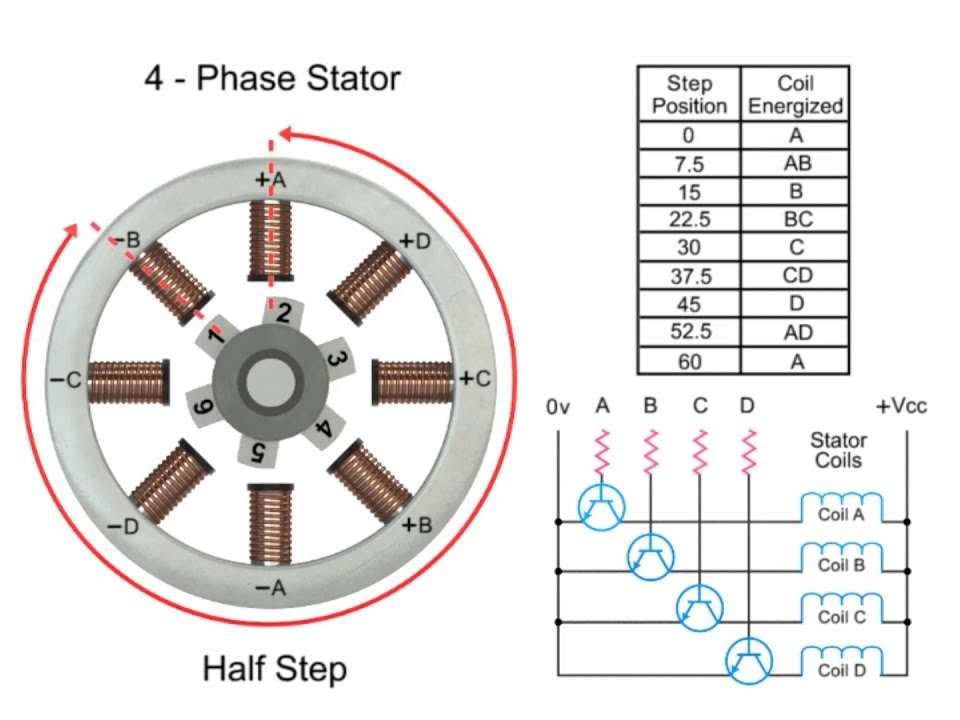

As already stated, a servo system operates within a closed-loop system. In such a system, the motor, or the device, is capable of continuously adjusting its output based on the feedback that comes back from its encoder. The feedback received in microns and nanoseconds helps the system ensure precise control over related parameters, including position, speed, torque, shape, etc.

In contrast, a conventional system mostly works in an open-loop system. Hence, the motion is only determined by the power that is being fed into the system. While open-loop control is certainly simple and quite effective, it cannot adapt to changes and might lead to jitters or over-collapse under changing external loads.

- Accuracy Of Position And Positioning

Due to their closed-loop control, servos are designed to ensure precise movement and speed, along with repeatability. This makes them ideal to be used in automated systems where repeated motion is required, including packaging lines and certain robotic belts. The closed-loop system helps servos execute exact motion profiles with minimal deviation, even over repetitive cycles.

Conventional electric setups, on the other hand, do not have any such feedback that helps guarantee positional precision and accuracy. They are bound to show deviation under varying conditions. However, when approximate control of positioning is required at an affordable cost, generic systems take the lead.

- Feedback and Sensing Mechanisms

Feedback devices, including encoders and resolvers, are probably the most important part of servo solutions. These integral parts act as the brain of such systems, providing continuous real-time information about the motor position, speed, and accuracy at every microsecond. This feedback is what enables corrective action in real time.

Conventional setups generally lack any such feedback system. These setups usually do not have any sensing mechanism that can provide feedback to the brain of a motor at all. Hence, conventional setups do not have any option but to rely on fixed electrical inputs, which overlimits their overall ability to ensure corrective deviations during operation or adapt to externally changing loads.

- Speed Regulation and Torque Control

Servos offer fine-grained control of speed and torque across a wide range of operations. This also includes zero-speed holding, rapid acceleration, and deceleration. Conventional and generic systems, on the other hand, can only provide stable speed under steady conditions.

Moreover, precise torque regulation is something such conventional setups struggle with, particularly during start-ups and low-speed operations. Under rapid load changes, generic motors unfortunately also fail, especially when external conditions keep changing.

- Overall System Complexity and Integration

Servo solutions mostly require additional components such as drivers, feedback devices, tuning parameters, as well as additional coding to be integrated into a system. This increases the overall complexity of working with them, and only engineers and experts are capable of dealing with these systems properly.

However, most advanced servo solutions now come with improved integration capabilities and connectivity with PLCs, motion controllers, and other industrial networks. This makes their overall integration much simpler.

Conventional setups, on the other hand, are very simple to integrate into any system, with fewer hardware components or coding needed. This makes them an easy option to use when expert guidance or experience is not available.

- Performance under Varying Load

Under changing external loads and conditions, servos are capable of automatically adjusting themselves and amending their output to maintain consistent performance. This makes them ideal for situations where variable resistance or dynamic motion is common.

Conventional setups, on the other hand, may experience speed drops, increased current draw, or instability, and may jitter or ultimately lose functionality when subjected to fluctuating external loads and conditions.

- Energy Efficiency and Power Saving

Modern servo solutions are optimized to ensure minimal power usage by delivering torque only as and when required, rather than delivering it at every moment. Such working improves the overall efficiency of these systems under variable operating conditions and makes them an absolute power saver when used in bulk.

Conventional motors, on the other hand, are generally efficient in constant-load applications. However, they keep on delivering torque in a consistent manner, which may waste energy during load fluctuations and partial-load operations. This lack of power saving makes them an expensive option in industries where they have to be used continuously in bulk.

- Reliability and Maintenance

Servos typically have less mechanical wear. Servos are brushless motors, and most of the servos used in industrial automation are generally brushless AC motors. In such setups, there is no friction or resistance to internal components, and hence there is less mechanical wear. Moreover, modern servos also come with built-in diagnostic abilities that support predictive maintenance beforehand.

Conventional setups, however, work with brushes that wear over time due to resistance and continuous friction. Although these setups are easy to maintain, they lack condition monitoring and hence can trip at any time.

- Cost and Total System Investment

Servo solutions are modern and come with advanced technologies. This makes it understandable why they come with higher upfront costs compared to conventional setups, which are quite affordable.

However, due to their proactive abilities and self-monitoring features, servos can reduce long-term costs while also ensuring reduced overall downtime and higher productivity. Conventional motors lack such cost-saving abilities and may incur higher costs in applications where they are used continuously and undergo extreme wear.

- Scalability and Flexibility

Servos are highly scalable and adaptable. They can be used in complex multiaxis and multidimensional systems, making lengthy connections between different solutions that work together in harmony. Their flexibility and scalability make them ideal for automation and for processes where optimization is required.

Conventional setups, however, are not as flexible or advanced as servos or steppers. Hence, they remain effective for short-term fixed functionality and are mostly reliable only for single-speed applications.

Application Suitability and Use-Case Alignment

Only knowing the above differences is not enough to choose the right option between a servo and a generic conventional electric motor. Rather, this decision ultimately depends on how closely the capabilities of a specific system align with your functional demands, as well as the overall operating conditions of the system application.

It is important to understand that none of these options is universally superior, and each will deliver optimal value when applied wisely in the right context. Understanding the alignment of a specific motorized solution with its overall system working and requirements is what helps avoid over-engineering or performance compromises.

If you are looking to invest in a motorized setup for applications where precise positioning, controlled motion, and repeatability are demanded, we strongly suggest going for servos. In robotics, CNC, AGVs, and automated assembly line systems, even the smallest deviations in speed, precision, or motion can affect the overall working quality or productivity of the system.

In systems where synchronization is non-negotiable, going for anything other than a servo is a mistake. Servos excel in such environments when they are maintained accurately and are allowed to ensure control under dynamic loads and frequently changing external speeds.

On the other hand, if you want to invest in a unit for applications where continuous rotation, steady operation, and simple speed control are more of a need, going for a conventional electric setup is a good idea. For example, it is common for pumps, fans, conveyors, simple household equipment, and compressors to operate under predictable load conditions. In such systems, feedback-based motion control adds little to no practical value, and hence, the simplicity and cost efficiency of conventional setups make them ideal for such cases.

If you want to invest in a setup for any high-speed multi-axis system, we suggest going for servos because of their ability to synchronize motion across multiple devices. This coordination is essential in packaging, printing, and material handling systems because, in such systems, timing accuracy directly impacts the overall working of the system.

If you want a solution for harsh or rugged environments, conventional devices are often the way to go. These are mechanically simple and hence are very tolerant of dust, heat, and vibrations. However, modern servos now come with appropriate enclosures and industrial-grade components to perform reliably in demanding conditions when applied correctly.

Cost sensitivity is another important factor to consider when looking for the right fit between multiple motorized solutions. While servos deliver high system-level value and are perfect for smart systems, their precision and ability to self-correct may not always translate into measurable gains. In such cases, conventional motors provide a more economical solution.

Application Suitability Comparison Table

| Application Type | Servo Motor Suitability | Conventional Motor Suitability | Primary Reason |

| Robotics & Automation | High | Low | Requires precise, synchronized motion |

| CNC & Machining Centers | High | Low | Accuracy and repeatability are critical |

| Packaging & Labeling | High | Moderate | Fast response and timing accuracy |

| Material Handling Systems | High | Moderate | Variable loads and dynamic control |

| Pumps & Fans | Low | High | Constant-speed operation |

| Conveyors (Simple) | Low | High | Minimal positioning requirements |

| Printing & Textile Machinery | High | Moderate | Tension and registration control |

| Compressors | Low | High | Continuous duty operation |

Limitations and Trade-Offs

Although both servo and conventional electric systems have their own distinctive benefits, both of them come with certain limitations that one must consider when integrating them into a system design. Ignoring the trade-offs and limitations of both setups can result in mismatched performance expectations or unnecessary downtime.

Servo systems introduce higher system complexity because they rely on feedback devices, servo drivers, and control algorithms. This complexity increases the time required for the initial setup and demands careful parameter planning and tuning if stable and reliable results are to be achieved. Inadequate tuning and poor integration can lead to faulty systems, oscillations, noise, and vibrations.

From a cost-related perspective, servo systems often represent a higher total investment. Beyond the system itself, there are additional expenses required for their deployment, including investment in encoders, drivers, shielding, cabling, and more advanced controllers. If you are looking to set up a system where precision is not extremely critical, this added cost may not be worth it.

Servos also often require a clean and stable environment for proper operation. These systems do not work well with electrical noise, improper core grounding, or poor cable management, as such issues can degrade overall signal feedback, affecting accuracy and reliability. Additional protective measures may be required in harsh environments for servos to work properly.

Conventional systems, on the other hand, are simpler and more rugged. However, they lack the ability to actively correct for load variations. Under changing external conditions and loads, speed and torque deviations commonly occur, affecting overall system consistency.

Another trade-off involves energy efficiency under varying loads. While conventional motors are efficient during steady operation, they tend to consume excess energy when load conditions fluctuate repeatedly.

Ultimately, the decision is determined by control precision and system simplicity. Servos prioritize performance and adaptability, while conventional systems emphasize ease of use and cost efficiency.

Decision Framework: Choosing Servo Motor vs Motor

Knowing all the benefits, use differences, as well as the disadvantages, the ultimate decision of selecting the appropriate motorized technology requires a structured evaluation of application demands rather than simply preferring a particular type.

Below are the measures you can take to ensure an appropriate motorized system choice:

- Defining motion control requirements

- Evaluating load-related characteristics

- Considering the overall system integration complexity

- Assessing cost and performance impact

- Viewing environmental constraints as well as maintenance requirements

- Planning for scalability and future expansion

Get Your Servo And Conventional Solutions From DMKE Today

At DMKE, our experts are capable of providing you with both servo and conventional solutions. Depending on what you need, we can offer ready-made, high-quality solutions, along with customizing your motors based on your requirements.

All our offerings undergo rigorous eight-step testing prior to sale and are made with the highest quality components to ensure that they deliver the absolute best results under all conditions.

Visit our website or connect with us today to start your consultation and find the best motor solution for your system.