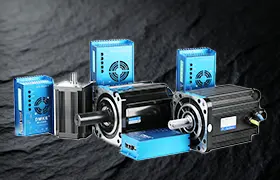

BLDC Motor

- DMKE

- Brushless DC Motor

- BLDC Motor

BLDC motors are known for their high efficiency, reliability, and low maintenance due to their electronic commutation and lack of physical brushes.

About BLDC Motor

Brushless DC (BLDC) motor without a gearbox operates as a direct-drive system, offering several distinct characteristics beneficial for precision applications. These motors are known for their high efficiency, smooth operation, and excellent speed control across a wide range, often achieving speeds up to 9,000 rpm or more, depending on the model. Their brushless design eliminates friction and wear from mechanical commutation, leading to a long service life, low electrical noise, and minimal maintenance needs.

| BLDC Motor Without Gearbox | ||||

| Rated Power(W) | 10W to 35KW | |||

| Rated Voltage(V) | DC 12V,24V,36V,48V,72V,96V,310V | |||

| Flange Size(mm) | 42,57,60,80,90,110,130,180,220 | |||

| Rated Torque Range(N.m) | 0.063 to 100N.M | |||

| Rated Speed Range(r/min) | 750 to 25000 | |||

| Remark:Power above 2000W not suitable for high speed motors | ||||

The Silent Pulse of Modern Medicine-BLDC Motors

In critical care, where precision and reliability are non-negotiable, the heartbeat of advanced medical equipment depends on a superior force. Brushless DC (BLDC) motors have emerged as the silent, intelligent core powering the devices that save and sustain lives.

Ventilators & Anesthesia Machines

Acting as a patient’s “external lungs,” BLDC motors drive the blowers and compressors with exceptional control. They deliver the exact tidal volume and air pressure required, ensuring every breath is consistent and reliable, from gentle support for neonates to powerful cycles for adults.

By delivering a combination of silence, precision, and unwavering reliability, BLDC motors are more than just components—they are vital partners in advancing patient care and enabling the next generation of medical technology.

Infusion Pumps & Syringe Pumps

In drug delivery, accuracy is everything. BLDC motors provide smooth, pulse-free, and precisely metered flow rates. This eliminates dosing inaccuracies, ensuring patients receive the correct therapeutic amount down to the microliter.

Why are BLDC motors the preferred choice for such critical applications?

Exceptional Reliability & Longevity

With no physical brushes to wear out, BLDC motors offer a dramatically longer operational life. This reduces downtime and maintenance, which is crucial for life-supporting equipment that must operate 24/7.

Quiet and Smooth Operation

The absence of brush friction and arcing results in exceptionally low noise and vibration. This contributes to a calmer environment for patients in sensitive care units and allows for smoother operation in precision instruments.

Precise Control and High Efficiency

BLDC motors provide exact control over speed and torque, instantly responding to digital commands. This enables accurate dosing, stable airflow, and lower power consumption in portable devices.

Minimal Electromagnetic Interference (EMI)

Designed for clean electrical operation, BLDC motors generate very little electrical noise. This prevents interference with the sensitive electronics found in other medical monitoring and diagnostic equipment.

Why DMKE

In-House Production with 150+ Workforce

Wide Power Spectrum: 5W to 25KW Brushless DC Motors

16+ Years of Motor Industry Expertise & Application Knowledge

Integrated Motor & Drive Systems for Seamless Responsibility

Free Expert Pre-Sales Engineering & Selection Support

ISO9001, CE & RoHS Certified Quality Assurance

40+ Patents & 20+ R&D Engineers for Custom Solutions

Professional & Responsive After-Sales Technical Support