Motors exist in almost every machine from home appliances to heavy industrial machinery. Yet despite having the same purpose (turning electric energy into motion), not all of them work the same.

Many rely on brushes for transferring electricity to the rotor and mechanically switch the direction of the magnetic field. This system works but it also introduces friction, heat, and as a result: wear over time.

Others eliminate brushes entirely and depend on electronic control to deliver power. But how? We’ll find that out in this in-depth guide that doesn’t only explain, “what is a brushless motor” but also delves into whether you should invest in one or not.

Why Do Motors Come in Different Designs?

Before we explain what brushless motors are, we’d like to expand on the statement presented in the introduction.

Like we mentioned earlier, these power houses show up in nearly every device that moves, spins, lifts, or pumps. Their goal is quite similar: convert electrical energy into motion but the way they achieve that can vary.

A major dividing line comes from the presence of brush. In brushed ones, small carbon brushes make contact with a spinning part which is called the commutator. This mechanism delivers electrical current to the rotor and keeps the motor turning. This method is simple and inexpensive. Because of this reason, brushed ones are still common in basic tools and low-cost devices.

However, the same physical touch that makes brushed ones so straightforward also limits them. The friction between commutators and brushes creates heat, causes gradual wear, and introduces small losses in efficiency.

Brushless motors solve this exact problem. When brushes are removed, they are replaced by electronic control. No brushes means no friction means no wear-and-tear means no loss of efficiency.

In later sections, we’ll do a more in-depth comparison of both: brushed and brushless. But for now, let’s explore the anatomy and workings of a brushless DC motor.

The Anatomy of a Brushless Motor

In previous sections, we touched on the basics of a brushless motor i.e., it doesn’t have a brush and its basic benefits. But if it doesn’t have a brush, how is it supposed to work and increase efficiency of your machinery? To comprehend that, let’s first understand its anatomy i.e., the components that make a brushless motor work efficiently.

Stator

First, we have the stator. It’s the non-moving part and foundation of the entire system. It holds the copper windings (we’ve explained the windings below too) which are the coils that create a magnetic field when electric current flows through them.

In a brushless motor, the stator is usually on the outside, while the rotor spins inside it (though some designs reverse this arrangement).

What matters most about the stator is how evenly and efficiently it produces a rotating magnetic field. Since there are no brushes, the stator depends on electronic signals to energize the right coils at the right time.

Rotor (Moving Part)

Like the name suggests, the rotor is a part that actually spins. It has permanent magnets that are arranged around its circumference.

Rotor design directly influences performance characteristics:

- Number of magnets: more magnets typically improve smoothness and torque consistency.

- Magnet material: stronger materials create a more powerful magnetic field.

- Shape and positioning: these determine how efficiently the magnetic fields interact.

Because the rotor doesn’t rely on physical contact with brushes, it experiences far less wear. This is one of the reasons brushless motors last much longer than the brushed motors.

Windings

As mentioned earlier, the copper windings are wrapped around the stator’s iron core.

Their job is to produce magnetic fields when powered. Brushless motors can have different winding arrangements (such as star or delta). Although the specifics can be different, the core idea stays the same: the windings shape how the magnetic field develops and how the motor responds to load.

Good winding design leads to better efficiency, lower heat, and more predictable torque. And of course, the poor winding design results in wasted energy, uneven performance, as well as the unnecessary heating.

Permanent Magnets

These magnets are super critical as they replace the rotor (that’s based on electromagnetism) used in brushed motors.

Their strength and temperature resistance influences the motor’s reliability and power capabilities. That is why stronger magnets make the apparatus more responsive + the heat-resistant materials prevent performance drop during large or demanding operation.

Commutation System (Power Switchers)

Commutation means shifting current to the right coil. In brushed motors, it happens mechanicaIIy using brushes touching a spinning commutator. Brushless motors replace this contact with electronic commutation, controlled by an external device called an ESC (electronic speed controller).

The commutation system determines:

- when every coil is energized,

- how fast the magnetic fields rotate, and

- how smoothly the engine spins

This electronic approach is the primary reason why brushless DC motors or brushless servo motors deliver higher efficiency and longer lifespan. The speed controller (ESC) reads the position of the rotor. It does so either through sensors or by interpreting electrical feedback. It also adjusts the delivery of power in real time.

Shaft and Bearings (for Support)

Shaft / bearings are essential for support purposes. The shaft shifts the turning of the motor to whatever it’s driving. Bearings, on the other hand, keeps the movement stable + reduces friction.

How Does a Brushless Motor Work?

It might seem like some kind of magic at first but once you understand the process, it starts making sense.

Input

Like many engineering processes, it starts with an input. The input could be in the form of information, action of a user, or it could be data that’s coming from another part of the process.

Then, the system moves this input into a processing stage where it’ll check what the user is trying to do and what rules to apply to these instructions. This input is critical because it prevents error and keeps it running consistently.

Processing

Once the system understands the input, it will apply a set of instructions that are predefined. These instructions are super helpful as they tell the system how to handle almost all situations it could face.

Output

Once instructions are applied, it’s time for the system to create an output. It could be a result, an update, change on the screen, or simply: a response back to the user.

Update

Behind the curtains, the system is always keeping track of everything. It will store what it needs and discards what it does not need. There will also be updates on any parts that rely on the new information. This way, the system keeps on growing by learning from minor issues.

Summary

Overall, the system follows the same loop every time:

- take the input,

- process it,

- apply the rules,

- deliver the output, and

- update what’s necessary.

By repeating this loop consistently, it works in a way that feels simple to the user, even though multiple steps are happening under the hood.

Main Types of Brushless Motor

Yes, brushless motors have further types too. Every type is built to solve different problems. That is why, we suggest you read this part of the article with care as it’ll help you determine which type of brushless motor is right for your needs.

Inrunner

The inrunner has the rotor on the inside. The stator is wrapped around it. This design exists to allow the rotor to spin at very high speed with relatively low torque.

But why? It’s handy for applications where fast rotation matters more than force. That is why these are easily found in remote control vehicles, small drones, and other compact tools.

Outrunner

The outrunner flips the design. The rotor is on the outside and spins around the stator. This layout naturally produces higher torque at lower speeds. Because of this, you won’t need as much gearing + the motor feels more powerful even at modest RPM.

This makes the outrunners ideal for gimbals, electric bikes, automation equipments, and conveyors that need a steady, strong output. In simple terms, inrunners are about speed, while outrunners are about usable force.

Slotless or coreless brushless motor

Slotless motors remove the traditional iron core that’s found in most stators. Without the metal structure, the rotor can spin with very little resistance. The result is a smooth and vibration-free performance.

They also tend to be lightweight and respond promptly to quick changes. This makes them popular in health devices, high-precision tools, and anything that requires minimal sound or exceptionally smooth motion. They aren’t designed for heavy loads but excel in accuracy and responsiveness.

Brushless Motors in Real Life

Brushless motors are not specific to one industry. They appear where reliability / quiet operation / efficient performance matters.

In daily consumer products, these power devices like cordless vacuums, drones, and power tools. Vacuums use them because brushless motors deliver strong suction without overheating during a long cleaning session. Drones rely on them for their balance of light weight + quick response + precise speed control, all of which are essential for stable flight.

In vehicles, e-bikes and electric scooters often use the brushless ones. Riders don’t have to worry about worn brushes, and the apparatus can handle daily use without drops in performance.

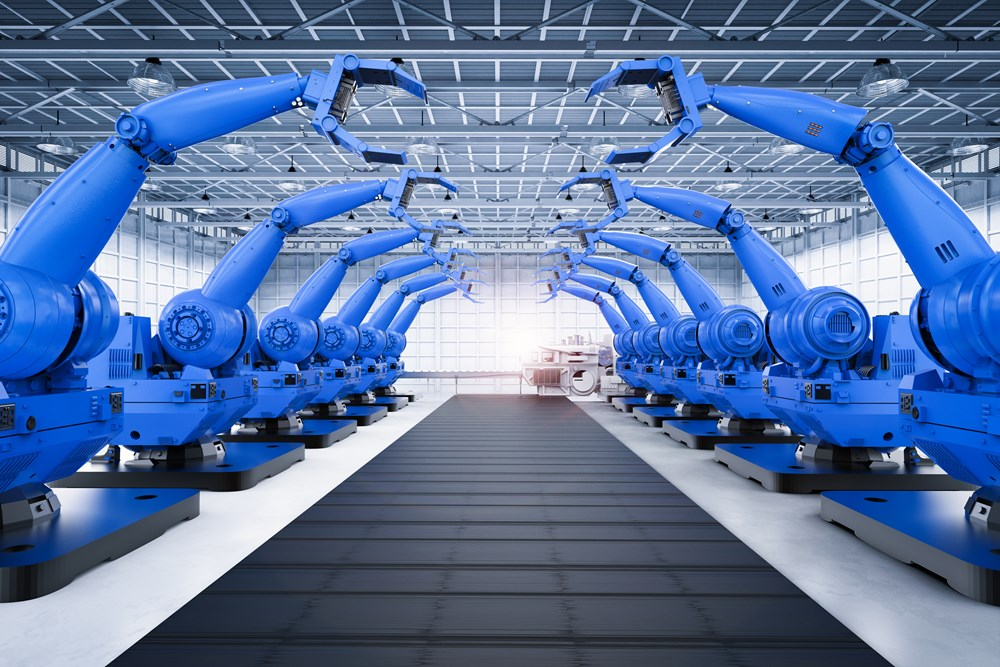

On the industrial side, brushless motors appear in CNC machines as well as packaging lines. These machines run for long hours (sometimes continuously) so durability becomes more important than the cost of replacement parts.

In the medical field, brushless motors power ventilators, surgical tools, imaging equipment, and lab automation systems. A ventilator, for example, should run around the clock without unexpected failures. Surgical devices need precise, vibration-free rotation to maintain accuracy.

Quick Comparison: Brushless vs. Brushed Motors

Brushed and brushless motors have the same end goal, but the way they achieve that motion leads to very different results in real use.

| Factor | Brushless | Brushed |

| Efficiency | high | moderate to low |

| Durability | long lifespan | brushes wear out |

| Noise | low | higher |

| Control | smooth and precise | less consistent |

| Cost | high upfront | lower upfront |

Practical Guide on Choosing the Right Brushless Model

Selecting the right brushless DC motor or brushless servo motor doesn’t have to be complicated. The best way to approach it is to evaluate your application step by step. When you look at the following factors in an organized way, the “right motor” becomes much easier to identify.

Understand requirements of your load

First, you have to determine the type of load. Is it going to be a fan, a wheel, a belt, a pump, or something being lifted? Each type of load behaves differently. For instace:

- A fan requires consistent speed and low torque.

- The conveyor needs steady torque at moderate speed.

- A robotic joint may need precise speed changes and holding torque.

Then, estimate how much force is needed.

Match the motor speed to the task

Brushless motors come with a natural speed profile. Some are built for high RPM (ideal for airflow or spinning tools), while others are optimized for slower, controlled motion.

Ask yourself:

- Does your application need speed, torque, or a balance?

- Will the system use gearing? If yes, the speed can be higher.

- Is the speed constant or does it change frequently?

Matching the motor’s speed characteristics to your actual requirement prevents noise, heat, and unnecessary power consumption.

Choose the right voltage and power level

Start by checking the power supply compatibility. The motor’s voltage rating should align with your available power source which can be battery or industrial power supply.

Then, understand how voltage affects performance. Higher voltage generally means higher potential speed, while lower voltage is good for compact applications that require less heat.

Consider the motor’s physical form factor

Brushless motors come in a variety of shapes and internal configurations. Choosing the correct form factor affects both: performance and ease of installation.

Evaluate operating conditions

Environmental factors have a major effect on apparatus life:

- Temperature: Consistent operation require better heat dissipation.

- Dust or moisture: Sealed motors may be required.

- Duty cycle: Motors running all day need better thermal performance than motors running occasionally.

Make sure your motor is optimal for the environment it will have to work in

Common Misconceptions About Brushless Motors

Let’s figure out the actual truth behind the four misconceptions about brushless DC motors.

“Too complex.”

Brushless motors may sound complex but the core idea is very simple. The process is also simple, just not as simple as a brushed motor since electronics are used.

The electronics that control them do the hard work automatically, so users rarely have to think about what’s happening inside. In everyday use, they’re actually easier to live with due of less maintenance.

“Always expensive.”

Brushless motors “used” to cost more but that’s not the case anymore. Prices have significantly dropped as they are used in various industries. But even if you forget the purchase cost, the lower maintenance and higher energy savings can give a better investment return than brushed motors where maintenance cost adds up a lot.

We’ve posted a detailed price guide for brushless motors. It can be read to get an idea on why brushless motors are a better option for your wallet.

“Only for high-end equipment”

While brushless motors are common in advanced robotics and drones, they’re also found in everyday products: fans, e-bikes, vacuum cleaners, and even office machines. Their reliability and smooth operation make them suitable for simple and complex devices alike.

“All brushless motors perform the same”

Not all brushless ones are built for the same job. Some are optimized for high speed while some for high torque and others for long operating hours.

Finally, Should YOU Invest in a Brushless Motor?

The decision comes down to how you will use your device and what you expect from it.

The benefits of brushless motors matter most if your equipment runs for long hours, needs precise control or must stay reliable with minimal maintenance. In those cases, the upgrade usually pays for itself over time.

You should strongly consider a brushless motor if you use tools or machines daily as you need a reliable one that won’t wear every now and then.

However, there are situations where sticking with a brushed motor makes sense. For example, if a device runs only occasionally or doesn’t require smooth speed control or has a very tight upfront budget: a brushed motor may be perfectly acceptable.

But if you are still confused, this quick checklist can help you out:

- Do you use the device frequently or for long hours? → If yes, go brushless.

- Do you need quiet, smooth operation? → Brushless helps.

- Is your priority the lowest upfront cost? → Brushed may be enough.

- Do you want reduced maintenance and longer lifespan? → Brushless is the better choice.

Conclusion

Brushless motors have become a core technology across modern machines. The reason is simple: they solve many limitations that can’t be escaped by brushed motors.

By simply removing brushes and relying on electronic control, brushless motors offer numerous benefits. These include smooth operation + great efficiency + long lifespan + better performance.

If you are considering purchasing a brushless solution, it helps to work with a supplier that understands the details. DMKE offers a wide range of brushless DC motors and brushless servo motors, integrated units, and customized options for projects that need something beyond off-the-shelf parts.

If you’re ready to explore options or simply want expert guidance, visit the product lineup and see what fits your application.