For novice buyers, buying a motor is mostly a tricky and frustrating business. You are stuck in markets, coming across similar-looking options during your quest to find the perfect one. You try to understand AC and DC options along with brushless and brushed ones, with data-heavy sheets that make no sense.

Sometimes, the performance claimed by different options on paper looks the same, but there are hefty differences in the pricing. Other times, it is natural for buyers to worry about long-term costs and maintenance costs while investing in a relatively cheaper option.

For many people, the AC and DC variations are easy to understand. However, many often get confused when comparing brushed vs brushless motor options. No matter which option you choose, your ultimate goal is just one. You don’t want to end up with a motor that promises high efficiency, looks great, but gives nothing compared to what its specs on paper claimed.

If you are also confused between different motor types and don’t know which one to choose for your purpose, this article is for you. Below, we will explain what differentiates the brushless and brushed systems, how they differ from one another and how to decide which suits your needs best. So, read on.

Core Differences Between Brushed & Brushless Motors

Whenever you compare two different motorised setups, no matter which approach you take, in the end, it is all about the power delivered by them and their assembly. No matter how similar two options look from the outside, the difference on the inside changes the entire story.

Below are the core differences between brushed and brushless motor options.

1. Working Mechanism

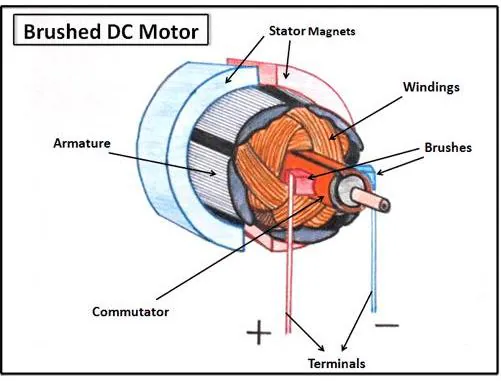

As its name states, a brushed motor uses carbon brushes along with the commutator to switch the current and keep the motor running and ensure the rotation. These brushes touch against the commutator. They are also physically in touch with some other parts of the system’s interior.

This ultimately means that in such an assembly, there is friction, wear and tear, and heat generation during longer operations.

A brushless unit, on the other hand, removes the problems arising from physical contact. It uses electronic control to switch the current and ensure rotation. Since everything is happening with the help of signals inside this magnetic assembly, there is no friction, no rubbing parts, and ultimately less heat generation.

Speaking of their major parts, a brushless motor comes with magnets, a stator, windings, and an external electronic controller. On the other hand, a brushed motor comes with a stator, rotor, commutator, and carbon brushes.

2. Durability + Wear and Tear

As already hinted, it is natural for brushed motors to experience friction and wear out quickly. This is because everything inside them is in physical contact with one another. Mostly, the brushes inside such an assembly are consumable, and with time, they easily get ruined, needing replacement.

The commutator in a brushed assembly also gets damaged under the influence of high loads or in inhospitable environments.

On the other hand, the brushless assemblies do not have this issue. Since there are no brushes inside, there is no friction. Here, the core components last longer, making this entire assembly ideal for continuous duty cycles. You’d be surprised to know that many BLDCs run for thousands of hours without any major maintenance needed.

3. Efficiency and Energy Losses

In brushed assemblies, the friction often leads the motor to lose its energy in the form of heat. This ultimately results in lower efficiency and less torque production.

BLDCs, on the other hand, operate at higher efficiency because in these assemblies, there is no friction that leads to energy losses as heat. This means such assemblies have smoother speed control, can produce more torque, and have a quieter operation.

4. Overall Design

A brushed assembly has a simple and cheaper overall design and sometimes comes in a huge size. This makes it suitable for people who are shopping for a motor on a budget or need a system for low-duty and less demanding applications.

Brushless assemblies, on the other hand, cost more than brushed ones, but require minimal maintenance and replacements. The brushless design also makes these motors quite portable and perfect for a long-term and professional or industrial setup where consistent running is common.

| Feature | Brushed Motor | Brushless Motor |

| Commutation | Mechanical (brushes) | Electronic (controller) |

| Components | Rotor, brushes, commutator | Rotor with magnets, stator, and external controller |

| Efficiency | Moderate, loses energy as heat | High, minimal friction losses |

| Maintenance | High brushes wear out | Low, minimal servicing needed |

| Lifespan | Shorter | Longer |

| Noise | Moderate to high | Low |

Performance Comparison

When comparing brushed versus brushless motor technologies, an in-depth analysis of the performance of each gives quite a clear contrasting picture. While the core working principle for every motor remains the same, i.e. spinning a load, how each of these behaves under different loads makes one more capable than the other.

Speaking of torque delivery, a brushed motor delivers decent torque when working at low speeds. However, its torque will drop at high speeds as heat builds up and brushes get ruined due to friction. Sometimes the mechanical switching between the electrical energy into the mechanical motion is not smooth, which also reduces the overall torque.

In a brushless assembly, however, stable torque is maintained across different speed ranges and changing loads. Its control is precise. Hence, the output rarely deviates from its initial path. This makes these motors the preferred choice for robotics, automation, and AGVs.

Speaking of speed control and responsiveness, brushed motors offer a quicker response but have a limited control range. When these assemblies move at low speeds, you will notice and hear vibration, roughness, and get an uneven feel.

Brushless assemblies, on the other hand, excel in their precision. They operate smoothly at low RPMs, and their instant response makes them perfectly capable of working at high speeds.

In brushed assemblies, the physical contact between the brushes and other parts of the assembly naturally produces some sort of vibration as well as noise that is easily audible. On the other hand, in BLDCs, the operation is quiet, and there are fewer vibrations.

Overall, if you want an assembly that quickly starts and sharply stops with offering precise positional control, BLDCs are your way to go. However, for general-purpose and low-effort tasks, brushed motors can do the job well without putting a lot of burden on your budget.

Cost Comparison (Initial vs Long-Term)

While comparing brushed vs brushless motor technologies, cost is often one of the major factors that one wants to consider to make the right decision. At first glance, brushed motors will be cheaper because of the affordable upfront price that they offer.

These motors come with a simple internal structure with no intense complex technology or coding that goes into their construction. This keeps their initial cost quite low, especially perfect for budget-conscious buyers.

Brushless setups, however, offer a more advanced technology and come with dedicated electronic controllers. All of this increases their starting price compared to the brushed versions. This higher cost reflects their precision and durability that they offer.

However, upfront cost is not the only cost that you should be comparing. Rather, energy consumption is another factor that one must look into when comparing brushless vs brushed assemblies.

Brushed motors lose more energy as heat and hence require more time to complete even simple operations. This makes them quite useless for continuous industrial setups. In such setups, high power usage over longer periods of time for even the smallest of operations can lead to an increased electricity bill.

In brushless assemblies, there is no loss of energy as heat. This reduces their overall energy consumption for the same task that a brushed assembly will do in 12 hours. While it is not noticeable, using such motors in industrial setups saves a lot of energy. This saving is reflected in the long-term electricity bills.

Speaking of maintenance costs, brushed assemblies require regular maintenance. You often need to manage replacements for them because of the friction that damages the brush and commutator inside them. This not only increases the downtime of the brushed operating system but also adds additional cost in terms of labour and replacement.

On the other hand, brushless assemblies don’t require a lot of maintenance and don’t undergo regular wear and tear. This means that there is hardly anything that an owner has to spend on them post-purchase.

All in all, even when brushed systems come with a noticeable price tag, the total cost incurred over their lifespan is not negligible. Brushed motors quickly wear out and require replacement. Hence, all of this adds up and becomes more than the initial low-cost price tag that they come with.

You must not favour a brushed assembly over a brushless one, thinking of it as an affordable option. Doing so, you might be making a mistake and buying yourself a lot of headaches with multiple downtimes.

| Factor | Brushed Motor | Brushless Motor |

| Initial Cost | Low | Higher |

| Energy Efficiency | Moderate | High |

| Maintenance Frequency | Frequent | Minimal |

| Downtime Risk | Higher | Lower |

| Lifecycle Cost | Moderate–High | Lower over time |

| Suitable Duty | Short/intermittent | Long/continuous |

Application Suitability Of Brushed vs Brushless Motors

After going through the above concepts, you might still not be sure as to what you should choose between a brushed vs brushless motor assembly.

In that case, we suggest you make your decision based heavily on where you intend to use the motor. Both these motors undoubtedly can do a similar sort of work, but their strength differs depending on the environment and the kind of workload that they face.

Brushed assemblies are often perfect for applications where you don’t want to spend a lot of money and usage is short-term and occasional. These are also ideal to be used in settings where there is not a lot of stress on the precision, and the performance demands are moderate.

It is common to find brushed assemblies in basic power tools, consumer devices, car accessories, and other low-duty home appliances that come at an affordable price.

Moreover, if you want to design an appliance that runs in short bursts and never has to perform long duty cycles, brushed assemblies are an ideal choice. For hobbyists, students, and school or college labs, these brushed systems provide an affordable and seamless way to deliver decent functionality.

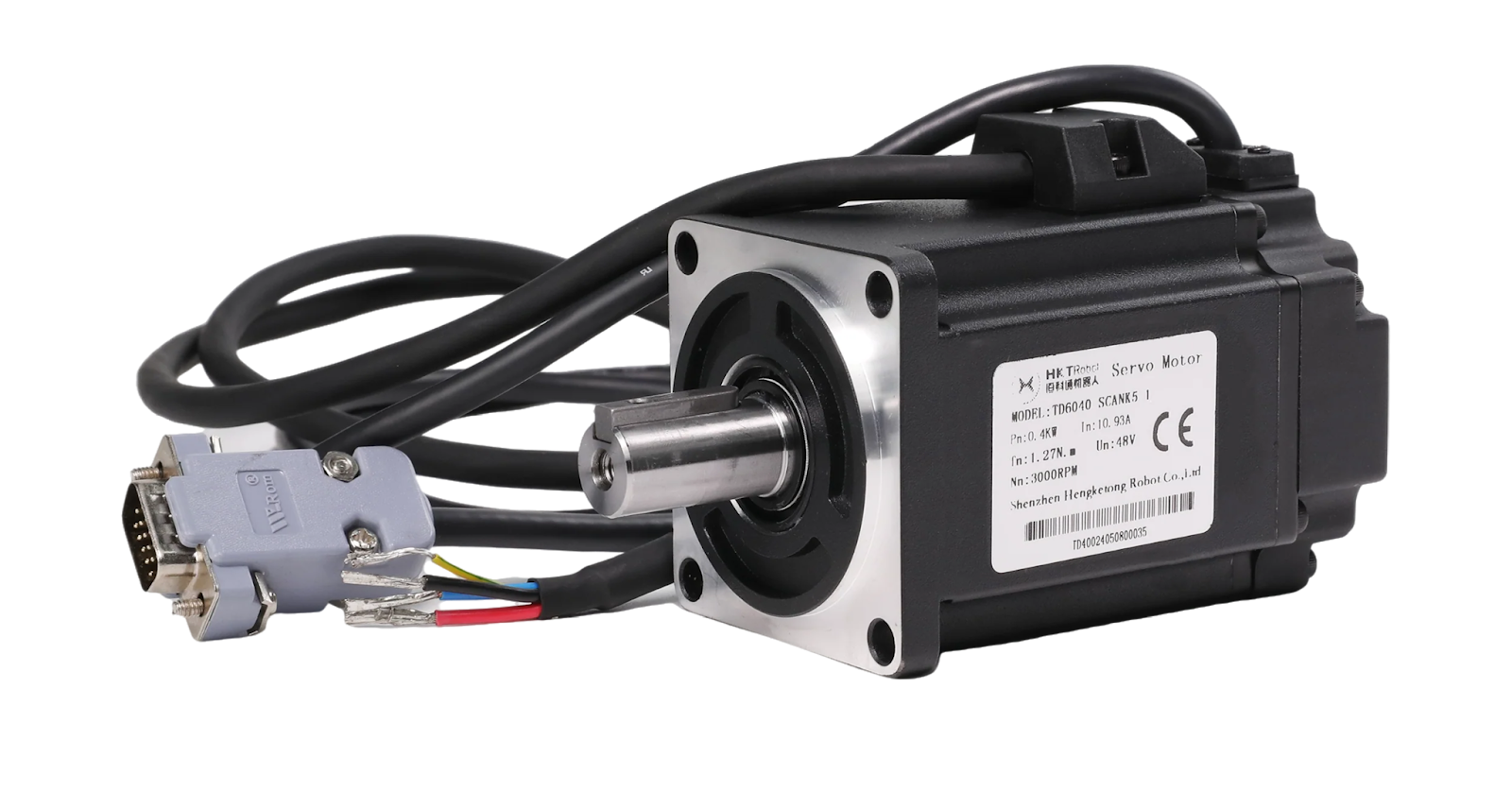

Brushless setups, on the other hand, are strictly built for high-precision environments where performance cannot be compromised. Industries including robotics, AGVs, AMR vehicles, drones, CNC machines, medical devices, and other automation packaging lines heavily rely on BLDCs and brushless servo motors.

These setups are also ideal for places where long work shifts are common. For medical scenarios where continuous low noise and non-vibrational working is required, brushless assemblies are an ideal option.

Operational Conditions For Brushless vs Brushed Assemblies

You can also consider the operating conditions to see whether a brushless or a brushed setup works well for you.

In dusty workshops and environments where vibration and heat are heavy, and downtime cannot be compromised, brushed setups won’t work. Brushed setups are also not ideal in assemblies where downtime is directly proportional to the losses and replacements are not easy to ensure.

BLDC motors, on the other hand, are perfect in such demanding environments without needing any sort of replacement or service.

Moreover, you can go for brushed assemblies when you are tight on budget and do not expect a lot from your motorised system. However, for engineering industry professionals and precision-based environments, only brushless motors will work well.

How to Choose the Right Motor for Your Use Case?

Making a choice between brushed vs brushless motors becomes easy when you look at your real-world requirements instead of just looking at the specifications of a motorised assembly alone. For each application, there will be different demands and requirements that a motor should match. Hence, the right motor for each case will differ.

To choose the right system for your needs, you first have to consider the duty cycle of your application. If you want something to run only for shorter intervals without sudden load bursts, you can go for a brushed assembly. However, the same would not be the case if you want the device to run for long hours without any breaks.

Load and torque stability are another factor that helps you make the right choice. Brushed appliances can handle simple loads but can’t provide stable torque. On the other hand, if you need consistent torque, smooth control, and repeatable motion over a considerable span of time, brushless assemblies are your best friends.

Lastly, you must look at your budget. If two different motors can perform the same task at hand, going for a brushed assembly helps you save money at the time of purchase. However, there might be additional costs associated with its maintenance and long-term usage.

On the other hand, a brushless assembly might be expensive upfront, but you won’t really have to worry about its maintenance costs or downtime.

Final Cost-Benefit Verdict

Choosing the final option between a brushed vs brushless motor ultimately comes down to only one thing: balancing your upfront costs with the long-term value that the motor can provide. Undoubtedly, brushed motors are affordable, and their simple design makes it easy to find replacements for their worn-out parts.

However, these motors are not perfect for industrial use because they are made to perform only low-duty tasks in a cost-sensitive manner. You can easily go for any brushed motor if you do not really care about precision, efficiency, or long-term working of your equipment.

BLDCs, on the other hand, come with hefty price tags. However, they save their owners a lot in terms of maintenance costs. These assemblies are perfect for industry usage, where minimal servicing and less downtime could help increase the overall efficiency of the task at hand.

If you need consistent high-performance results and can’t make any compromise on the precision and speed of your equipment, going for brushless options is a good idea for you.

Connect With DMKE For All Your Brushless And Brushed Needs

Regardless of the motor type you opt for, choosing the right supplier is what makes all the difference. At DMKE, our experts are ready to help you choose the best option between brushless vs brushed motors, depending on your real-world needs and budget.

At DMKE, you can find high-quality servos, BLDCs, and brushed solutions that properly meet your needs. We can also provide you with tailored support and guidance in choosing the right kind of setup among the brushed and brushless options, along with long-term reliability and post-sales support.

Visit our website or connect with us on WhatsApp today to get your hands on our ready-made brushed and brushless solutions, or place your order for custom motors.