As an industry owner or a professional in engineering fields, you’d agree that the electric motorized solutions are the backbone of modern industry, automation, and commercial advancement. They power everything from household appliances and large HVAC systems to industrial automation units, vehicles, precision control machinery, and much more.

While a great deal of attention is given to motor housings, shafts, bearings, controls, electronics, different motor types, and other internal components, the true heart of a motor often remains overlooked and is discussed far less than it should be. This heart is the winding of an electric motorized setup, which truly defines its overall working capability.

The quality, accuracy, and consistency of this specific part directly determine how a device behaves within a particular system. The cleanliness, efficiency, and seamlessness of the winding process determine the speed and torque a setup can deliver, its performance under heat, noise levels, and the overall value it provides.

When discussing windings, motor winding machines become extremely critical and should never be ignored. A winding machine is not just a production tool; rather, it is a highly precise system. The function of this system is to ensure the smooth placement of copper wire into stator or rotor slots with the exact tension and pattern required. These machines ensure that the copper wire is laid in a properly controlled manner while maintaining its insulation integrity.

In modern industries that manufacture high-quality motorized systems, these machines are given prime importance to ensure repeatability, reduce human error, and enable large-scale production without compromising the electrical performance of the motor. As motorized devices continue to become more compact, energy-efficient, and application-specific, the demands placed on these are becoming increasingly stringent.

Manual winding methods, once common, are no longer sufficient, as they cannot meet today’s standards of consistency, reliability, and control. As a result, automated and CNC-based setups have taken their place and have become essential equipment in motor manufacturing facilities worldwide.

In this article, we will take a detailed look at the working of a quality winding machine, from understanding its role in overall motor performance to exploring its major components, internal operating processes, levels of automation, and defect prevention methods. After reading this guide, you will be able to understand how these devices form the foundation of a reliable setup and why they are so important in the manufacturing of dependable electric motors.

Core Components of a Winding Machine

A motor winder, regardless of how advanced or cost-friendly it is, and irrespective of the type of device it is used for, typically consists of a few core components that make its operation possible.

Simply stated, it is a perfectly balanced combination of electrical, control, and mechanical systems that work together in harmony to achieve precise coil placement. The design of these machines may vary depending on the type of housing and the level of automation they are intended to provide, but the fundamental components generally remain the same. Below, we discuss these components one by one.

1. Winding Head Or Flyer Assembly

The winding head, often referred to as the flyer, is the primary component responsible for guiding the copper wire into the stator or rotor slots. This head usually rotates at controlled speeds while maintaining precise wire tension.

Some of its major functions include accurately placing the wire into the slots, enabling high-speed rotation for efficient production, and adapting to different stator or rotor geometries. In CNC machines, the movement of the winding head is typically synchronized with programmable motion control systems, allowing the overall assembly to handle complex winding patterns with ease.

2. Wire Tensioning System

Maintaining consistent wire tension is extremely important and almost non-negotiable for the proper functioning of any setup. Excessive tension can damage insulation and cause wire breakage. On the other hand, insufficient tension can result in loose windings and unevenly filled slots.

Tensioning systems in machines are equipped with mechanical tensioners, magnetic and servo-controlled tension units, and sensors that enable real-time tension monitoring. These systems can automatically adjust tension based on wire diameter, winding speed, and coil geometry.

3. Stator Or Rotor Clamping System

The clamping system securely holds the stator or rotor in its correct position during the winding process. Proper alignment of this mechanism is essential to ensure accurate slot targeting and to prevent mechanical damage during operation.

Most advanced solutions now feature adjustable fixtures in both rotor and stator clampers for different modes, to suit different setup sizes, along with pneumatic and hydraulic clamping capabilities. There is also quick-change tooling to reduce the overall time required to set up the system.

4. Control Panel And Software Interface

These control panels act as the overall brain and heart of any setup. In manual machines, these control systems are limited to performing functions such as speed and direction control. However, in CNC solutions, the control panels and software interfaces are quite sophisticated.

These panels allow engineers and setup operators to program the number of turns per coil, slot-skipping patterns, winding sequences, and layering. They also let them control the speed and acceleration profiles of the overall operation. This layer of control is highly important in advanced automation systems, as it enables high precision and makes the system adaptable to a wide range of industrial applications, as well as the electric motor housings.

5. Insulation Handling And Accessories

Most of the setups for winding are now equipped with auxiliary systems that handle slot insulation paper, interlayer insulation, and wedges. These critical components ensure electrical isolation between the coils and the motor core. Commonly, machines come with accessories such as paper inserters, wedge insertion units, and wire end-forming tools.

Types of Motor Winding Setups Used in Industry

All the winding setups can easily be categorized into one of their several types. These types are basically defined based on their design, the type of production they support, and the applications they are suitable for.

There are also categories based on housing design, production volume, and the level of precision required from their systems. Each type of machine is optimized for a specific industrial application. Some of the most common types are discussed below.

- Needle Machines

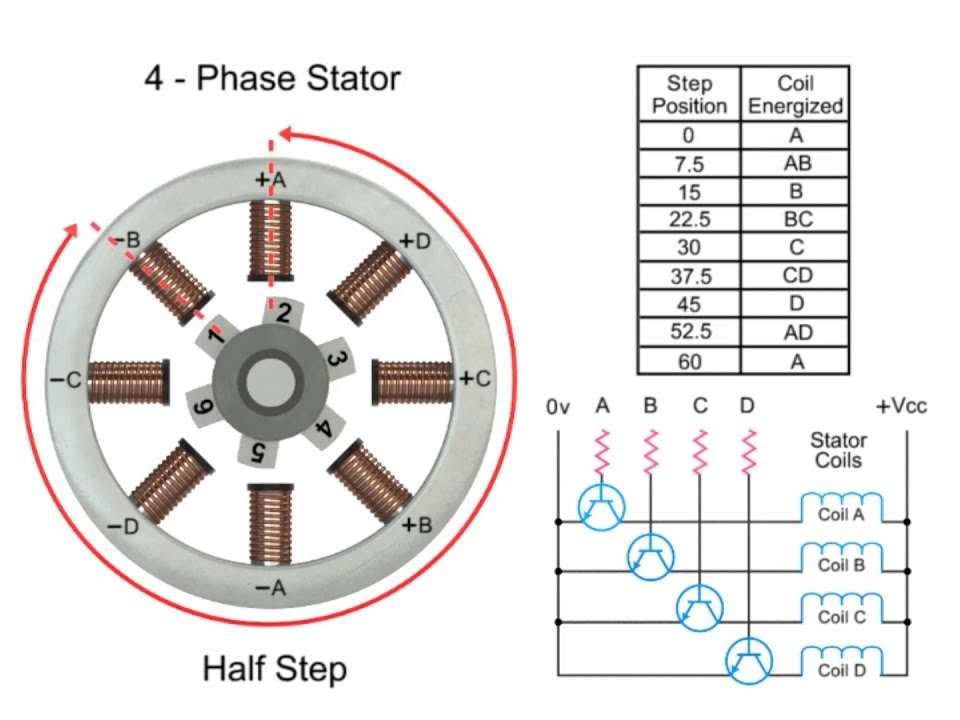

One common type of winding setup is the needle winding system, which is used for compact motors in portable and space-constrained systems where the slots are very narrow. Common examples include servo motors and stepper motors. In these solutions, a needle guides the wire directly into the slots, enabling very high slot-fill accuracy in compact geometries and limited functional spaces.

- Flyer Winders

Flyer winding machines are another common winding setup and are standard for use in induction motors. In these machines, a rotating flyer arm winds the wire at high speed, making the overall assembly highly suitable for medium- to high-volume production.

- Toroidal Winding Machines

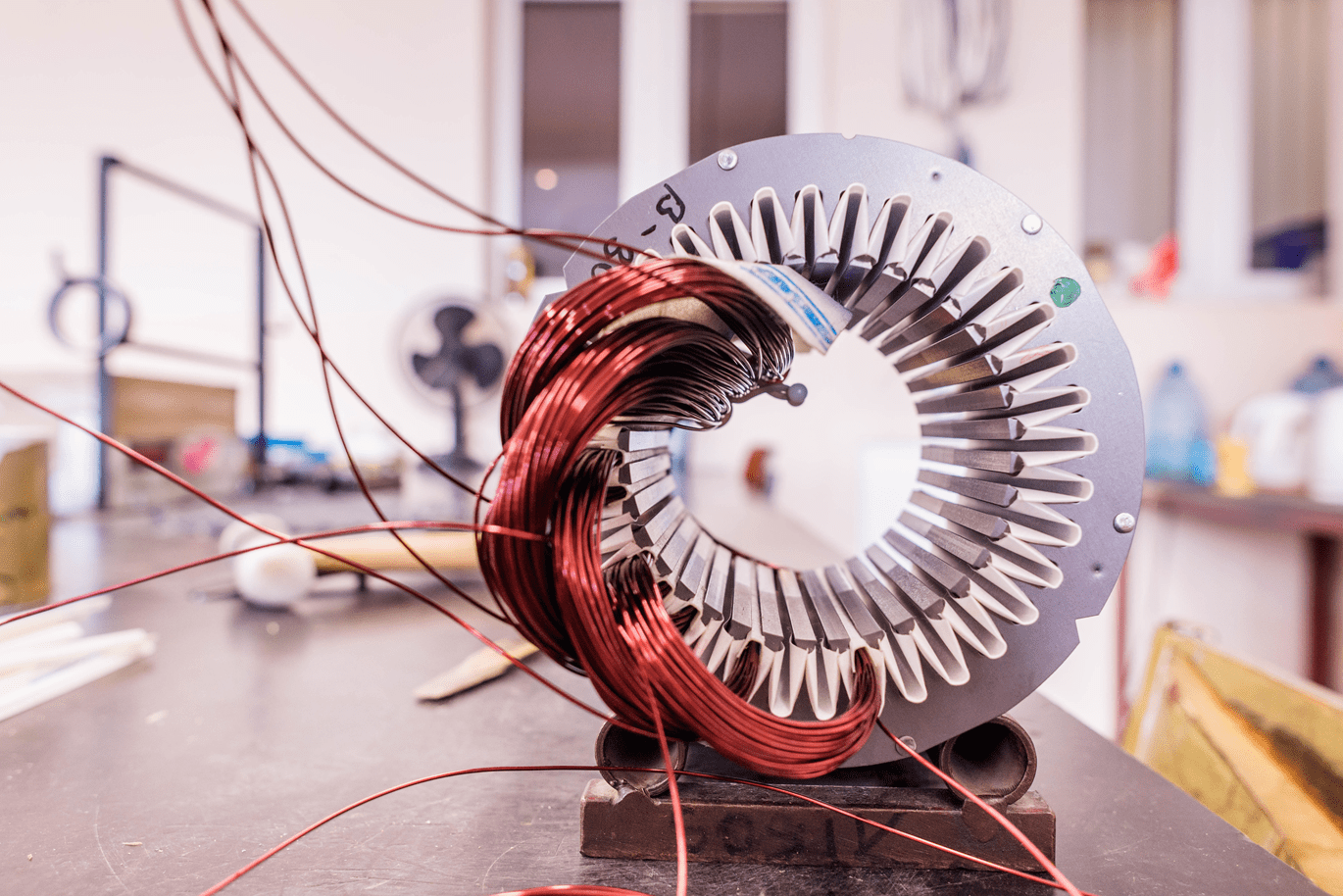

For ring-shaped cores and housings, toroidal winding machines are commonly used. These machines are often applied in transformers and other specialized devices, as they ensure uniform winding around closed magnetic cores.

- CNC Machines

Another common and widely used category is CNC machines, which are ideal for high-volume industrial manufacturing. These are currently the most dominant type of winding systems, offering complete flexibility, high repeatability, and the ability to handle complex winding patterns with ease. The choice of machine directly impacts efficiency, quality, and the overall performance of the motorized system.

- Armature Winding Machines

Lastly, armature setups are commonly used in DC motor setups and traction systems, where coils need to be wound around rotor cores instead of stators.

Step-by-Step Working Process of a Motor Winding Machine

The overall working of a winding setup is quite simple, but understanding the complete process can seem lengthy at first. This process becomes much easier to grasp when it is broken down into simple steps. To understand everything better, one must have a strong foundational understanding of how an electric motor operates.

Below, we break down the step-by-step working process of a machine in the simplest possible manner for clear and smooth understanding.

The process begins with stator or rotor loading. In this stage, the core is securely clamped to ensure precise alignment. At the same time, slot insulation paper is inserted to prevent electrical contact between the copper windings and the motor core or housing.

The second step involves setting the parameters. These include wire diameter, the number of turns, and the required winding pattern, all of which are defined through the control panel. In CNC machines, these parameters are pre-programmed, making the process more accurate and consistent.

The third step is the actual winding operation. During this stage, the flyer or needle guides the wire into the designated slots, while the tensioning system maintains consistent wire tension to ensure smooth and proper insertion. Sensors continuously monitor wire position and tension in real time. In advanced systems, feedback from these sensors allows the machine to make corrective adjustments during operation.

Once the process is complete, the machine performs wire cutting and lead forming. This prepares the coil ends for electrical connection. The finished stator or rotor is then unloaded and sent for further processes such as lacing, impregnation, or testing. This entire process is highly repeatable and ensures uniform winding quality across every motor produced.

Automation Levels: Manual, Semi-Automatic, and CNC Winding Machines

Depending on how they operate, their internal assembly, and the level of automation they offer, winding machines can be categorized into different automation levels.

The most basic and common type is the manually working solution, which relies heavily on the skill of the operator and the task being performed. These machines are mostly suitable for low-volume production, prototyping, or repair work due to their cost-effective nature. Although they are affordable, they offer limited consistency and speed and are not reliable for heavy-duty or high-volume operations.

When partial automation is required for key functions such as wire guiding and tension control, semi-automatic winding solutions are a better option. In these machines, loading and unloading are performed manually, while several critical winding functions are handled automatically. They offer a good balance between productivity and cost and are widely used for mid-scale production.

For the highest level of automation, CNC motor winding setups are an ideal choice. In these machines, all major coiling and wiring functions, along with loading and unloading, are fully automated. This significantly reduces the need for manual intervention and ensures maximum precision, repeatability, and efficiency.

Due to minimal human involvement, these machines are capable of performing complex tasks at high speeds. They support advanced patterns, quick changeovers, and seamless integration with quality monitoring systems, while continuously monitoring every aspect of the process with high accuracy. As a result, they are ideal for large-scale industrial applications.

In general, the higher the level of automation in a machine, the better the production speed, consistency, and reduction in defects. Higher automation also results in less downtime and improved reliability, making CNC winding machines a critical component of any modern motor manufacturing setup.

Below is a comparison table of manual, semi-automatic, and CNC winding machines, highlighting their automation level, operator involvement, accuracy, and other key features that help in selecting the most suitable option.

| Feature / Parameter | Manual Machines | Semi-Automatic Machines | CNC Machines |

| Level of Automation | Very low | Medium | Fully automated |

| Operator Involvement | High (skill-dependent) | Moderate | Minimal |

| Winding Accuracy | Low to moderate | Good | Very high |

| Turn Count Control | Manual counting | Digital / assisted | Fully programmable |

| Wire Tension Control | Manual adjustment | Automatic tension control | Servo-controlled, real-time |

| Production Speed | Slow | Medium | High |

| Consistency | Variable | Consistent | Highly repeatable |

| Setup & Changeover | Simple but time-consuming | Moderate | Fast with stored programs |

| Defect Rate | High | Medium | Very low |

| Suitable Production Volume | Low / repair work | Medium batch production | High-volume manufacturing |

| Typical Applications | Maintenance, prototyping | Industrial motors | Servo, EV, precision motors |

| Cost | Low | Medium | High (long-term ROI) |

Common Winding Defects

While many underestimate their impact, even the simplest motor winding defects can directly affect the overall electrical performance, reliability, lifespan, and return on investment (ROI) of a system.

Some of the most common winding defects include uneven wire tension, an incorrect number of turns, insulation damage, and poor slot filling. These defects, although often neglected by inexperienced operators, can lead to overheating, vibration, reduced efficiency, and ultimately, system failure.

Modern winding machines are specifically designed to minimize these risks. They are equipped with automatic tension control systems that maintain consistent wire tension and prevent loose or overstressed coils. These machines also feature programmable turn counters that ensure the correct number of coil turns, eliminating human counting errors commonly associated with manual winding. To protect insulation, modern systems use smooth wire guides, controlled winding speeds, and precise slot alignment.

Additionally, sensors within these machines can detect wire breakage or misplacement in real time, allowing immediate corrective action or automatic machine stoppage. CNC winding machines further support process monitoring and data logging, enabling manufacturers to trace defects back to specific production parameters and make adjustments to prevent recurrence.

By standardizing winding processes and reducing dependency on operator skill, motor winding machines significantly improve production quality, reduce scrap rates, and ensure compliance with industrial standards. Minimizing errors through automation also results in reduced downtime, leading to cost savings and greater operational reliability.

Applications of Motor Winding Machines Across Motor Types

Winding machines are used across a wide range of motor types and industries, depending on their suitability.

In AC induction motors, these machines ensure consistent stator winding, which is ideal for industrial drives, pumps, and compressors. For DC motors, specialized armature winding machines handle rotor coils with high accuracy and minimal error.

In servo and stepper applications, precision needle windings are essential to achieve high torque density and smooth motion control. These applications often require tight tolerances and repeatable patterns, which only precision needle winding can reliably provide.

Winding machines are also critical in automotive and electric vehicle motors, where they help ensure efficiency, reliability, and improved thermal performance. Additionally, HVAC motors, household appliances, and industrial automation systems rely on automated, highly precise winding solutions to achieve large-scale production with consistent quality.

Across all applications, the ability of these setups to adapt to different motor designs makes them a valuable asset in modern manufacturing industries.

Your Assurance of Quality at DMKE

At DMKE, this deep understanding of motor winding isn‘t just theoretical—it’s the foundation of our manufacturing philosophy. We know that the precision of the winding machine directly dictates the performance, efficiency, and longevity of the final motor.

That‘s why we invest in the most advanced CNC winding technology and rigorous quality control for every stator and rotor we produce. We don’t just sell motors; we sell the assurance of optimal performance that comes from mastering the heart of the motor itself.

When you choose a DMKE motor, you are choosing a product born from unparalleled expertise in the most critical stage of motor construction. Explore our range of high-performance motors to see how this commitment to core precision translates into reliability for your application.