A brushless DC motor can not spin on its own. This magic happens thanks to a motor driver. It controls the timing and flow of electricity to the motor. Think of the driver as the rain of the motor which decides when to deliver power and how much.

Despite its immense importance, many teams treat the motor driver as an afterthought. They usually select the motor first and worry about the driver later, or don’t care about the driver at all. However, real world experiences show that this approach rarely works.

A right driver must align with the characteristics of YOUR motor and demand of YOUR application since each need is different.

Therefore, we made this guide that included five practical tips that can help you choose the right motor drive for your BLDC motor. These tips are in depth so take your time to read it and then make a wise decision.

Before Choosing a Driver, Understand What Role it Plays in Your System

Visualize a brushless DC motor (BLDC) and driver as a system. Just like your brain maintains an order in the body, a motor driver controls a BLDC motor. In a human body, the brain develops according to the needs of the body. Therefore, a motor driver has to be properly matched according to your motor.

If it’s not a proper match, even a high-quality motor will struggle with unstable speed and excessive heat. Obviously, these causes will result in an unproductive performance.

Not only that! The driver’s role goes way beyond simply powering the motor. It shapes how efficiently the motor can convert energy into motion. It also affects the noise and vibration which can be annoying to work with.

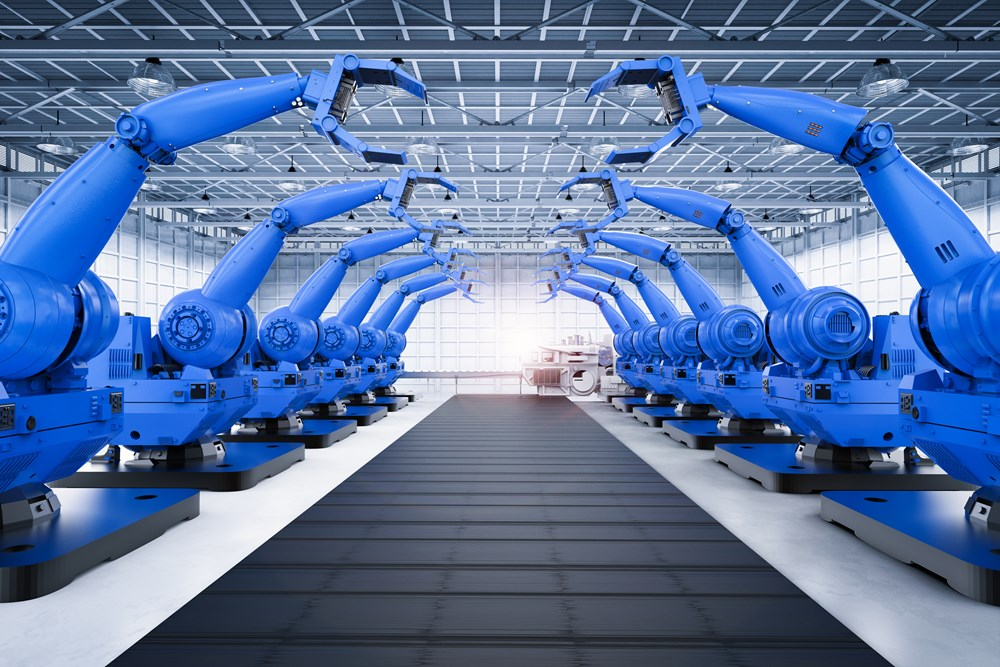

You might be thinking that a simple motor driver can work for your motor. However, that’s not the case since different applications impose different demands on a pair of motor and driver. For example, a robotic arm requires precise motion while a small pump prioritizes consistent performance, and a personal mobility device will need the ability to handle sudden change in load.

That is why it is important to visualize the motor and driver as a single system.

Now that you understand the role of driver, let’s understand how you can choose the right one for your BLDC motor. We have laid down five tips to help you with making a wise decision.

Tip #1: Check Whether the Driver’s Power Range Matches Your Motor’s Real Needs

Every BLDC motor has a rated voltage that indicates the level at which it operates most efficiently. So if you choose a driver with voltage that’s higher than the motor’s rating, it can lead to excessive heat and unnecessary noise. Both of these can lead to accelerated wear of components. On the other hand, a driver with low voltage can prevent the motor from reaching its intended speed or torque. This ends up causing a sluggish performance.

Therefore, it’s important to select a driver that supplies stable voltage that stays within the motor’s recommended range while also accommodating small variations caused by the power supply or temporary load changes.

Current Capacity and Peak Loads

BLDC motors rarely operate at a constant current. Startup, acceleration, or sudden increases in load can cause significant current spikes far above the motor’s continuous operating level. A driver chosen only for nominal current cannot manage these peaks, which may result in overheating, protective shutdowns, or even damage to the motor and driver. To prevent these issues, engineers must consider the driver’s peak current capacity, not just continuous current ratings.

This concept, often called “headroom,” provides a buffer to handle transient loads safely. A practical guideline is to choose a driver that’s capable of handling 25 – 40% more current than the motor’s typical running value. For example, if a motor draws 3 amps continuously but can spike to 6 amps under load, the driver should be rated at least for the peak and ideally have some additional margin.

Thermal Management and Efficiency

Even when the voltage and current specifications match, poor thermal design or low efficiency can limit performance. Motor drivers that generate excessive heat can reduce torque delivery and shorten the life of both the motor and the driver.

That is why it’s essential to evaluate the thermal characteristics of the motor driver. If a driver is well-designed in terms of heat dissipation, it can operate reliably under sustained and peak loads.

This means that you must check the datasheets for thermal ratings.

Practical Considerations for Real-World Applications

Choosing a motor driver only because of voltage and current ratings is a common mistake. Other factors that were explored in earlier sections of this tip must also be considered. And remember that each scenario will require different consideration in driver selection so it’s super important to analyze your needs first.

Tip #2: Decide Which Type of Motor Control You Actually Need

Picking the right motor driver goes way beyond matching current and voltage. Equally important is understanding the type of motor control your application needs.

The Three Common Control Styles

Motor drivers typically fall into three categories:

- sensorless,

- hall-sensor-based

- encoder-supported drivers

Each method differs in how it detects the rotor’s position and applies power to the motor windings.

Let’s start with the sensorless drivers which estimate the rotor position based on back EMF generated by the motor as it spins. They are mechanically simpler as no physical sensor is needed + they tend to be quieter at higher speeds.

Sensorless drivers work properly where smooth motion at moderate to high speeds is the priority and startup torque requirement is quite minimal. However, they can struggle with very low-speed control / high-precision positioning because the back EMF signal becomes weak or inconsistent near zero speed.

Then there are the hall-sensor drivers that use small magnetic sensors embedded in the motor to detect rotor position. This direct feedback allows for reliable startup and low-speed operation.

Hall sensors make the motor predictable + easier to control. This is why they are commonly used in robotics, pumps, and small electric vehicles. Although they are slightly more complex than sensorless drivers but provide better control across a wider speed range, especially at low speeds or during frequent start-stop cycles.

Lastly, the encoder-supported drivers offer the highest level of control. It does so by providing continuous feedback. These drivers are good for applications that demand precise motion control like robotic arms or CNC machines or automated assembly equipment.

Choosing Based on Your Application

The right type of control always depends on how the motor will be used. If it’s a simple fan or a pump, sensorless control is often sufficient (in fact, cost-effective). But you should avoid sensorless drivers if the system needs frequent changes in direction. Hall-sensor drivers, however, are a versatile middle ground.

Tip #3: Look for Built-In Protection and Heat Management

Even a perfectly matched driver can fail or cause problems if it lacks proper protection features and heat management. We have touched on heat and temperature before but in this section we’ll delve deeper.

Common Risks for BLDC Systems

Brushless DC motors often face several operational risks that can compromise its performance.

One common issue is an unexpected stall. It occurs when the motor is blocked or overly loaded. In a situation like this, the current spikes rapidly and generates heat. This potentially triggers the driver or causes damage to the motor.

Another risk is sudden surges in power. These are usually caused by fluctuations in the supply voltage or due to abrupt changes in load. These surges then put a stress on the electronics and affect the motor’s stability.

Overheating is another critical concern, especially in enclosed spaces where ventilation is limited like in compact robots or battery powered devices.

Driver Protections That Save Your Hardware

Modern motor drivers include built-in protections to mitigate these risks.

Features like overcurrent and overvoltage protection helps in automatically monitoring the motor’s electrical load. It also prevents damage during spikes.

Then there’s motor stall detection which can pause or limit the current if a stall occurs. Temperature monitoring is another crucial protection. It is often implemented as automatic slowdown or shutdown if the driver reaches unsafe levels.

Why Heat Design Matters Even for Small Motors

Even compact motors are susceptible to heat related issues.

Excessive temperature does not only affect the driver but also the other components of a brushless motor like windings, bearing, and electronics. Poor heat management will lead torque to drop and resultantly, reduce the efficiency.

If a driver has a proper thermal design, the operation will be consistent and there will be less thermal throttling. This becomes especially important in applications where the system is enclosed or ventilation is limited, such as small industrial devices, compact robots, or robots machinery.

Tip #4: Consider How You Want to Control the Motor

Since a motor driver is all about command, it’s important to consider the factor of control while choosing the right motor driver.

The “How” of Commanding a Motor

Motor drivers offer several ways to control a BLDC motor. The simplest method is analog or PWM based speed control. This approach allows the motor’s speed to be adjusted using a voltage input or a pulse-width modulated (PWM) signal.

It is straightforward, cost effective, and works well for applications where the motor only needs basic variable speed operation. Examples of this include small fans, pumps, or conveyor belts where precision positioning is not critical and speed changes are gradual.

A second method is communication based control. The interfaces of this one allow multiple motors to be monitored + controlled from a central controller.

Communication-based drivers are good for handling more complex tasks. This type of control is ideal for any application where the motor needs to respond intelligently to sensor input or remote commands.

Match the Interface to Your System’s Size and Complexity

The type of motor control interface that you will choose must be compatible with the size and complexity of your system.

If your project only requires basic speed adjustments, a simple analog or PWM interface is often sufficient. It reduces wiring and cost + it’s easier to implement.

It’s also worth considering how control requirements may evolve. A small project today might become more complex tomorrow, and selecting a driver that supports multiple control methods can save time and cost in the long term.

Tip #5: Consider the Installation and Future Support

Even a perfectly matched driver can cause frustration if installation or long term support considerations are overlooked.

Drivers Differ in How Easy They Are to Set Up

Not all drivers are created equal when it comes to installation and initial configuration. Some need manual tuning where parameters must be adjusted carefully. While the manual tuning can provide flexibility, it can also be time consuming and prone to error if the operator is not experienced.

Other motor drivers also come with software tools. These tools guide the users through the setup process and allow parameters to be adjusted graphically or automatically based on the specifications of the motor.

Some drivers are also pre tuned for specific motor models. This can significantly simplify deployment. Using these options, basic configuration will be often enough to start the motor in a safe manner.

Consider Maintenance and Troubleshooting

Long term reliability depends on ease of maintenance and availability of diagnostic features.

The drivers with built in diagnostics can alert users to overcurrent events or thermal warnings. This can help engineers to identify and correct problems quickly. Firmware support and documentation are equally important.

When It’s Smarter to Choose a Motor and Driver Pair from the Same Company

In many cases, purchasing a matched motor and driver set from the same manufacturer offers advantages. Matched sets are often optimized for performance and ensure that the torque curves and current handlings align perfectly.

No doubt, it is possible to mix and match both (motor and driver) from different manufacturers. However, doing so can introduce hidden challenges like unexpected thermal loads.

DMKE offers products that are designed to work seamlessly together. These matched sets reduce the complexity of setup and provide reliable performance.

Example Walkthrough

Applying the five tips to real world applications helps illustrate how different priorities affect driver selection.

Scenario 1: a small conveyor belt requiring stable speed

For a small conveyor belt that’s transporting lightweight items, the dominant factor is stable and predictable speed.

Using tip 1, you can ensure that the driver’s power range matches the motor. Similarly, tip 2 will help in selecting the right control method which could be a simple sensorless or a hall-sensor driver in this case.

Protection features (from tip 3) are less crucial here but it’s good to note them. A simple PWM or analog interface (Tip 4) is usually adequate, and pre-tuned drivers (Tip 5) minimize setup time and allow the conveyor to operate reliably.

Scenario 2: a service robot wheel motor

A service robot presents more demanding requirements. Startup torque and responsiveness are critical which makes the tip no. 1 and 2 highly relevant.

The motor must accelerate quickly and handle sudden changes in load without stalling. Communication based control interfaces (Tip 4) become super important as multiple motors may need to coordinate.

Is an Integrated Motor + Driver Module a Better Option?

An integrated motor and driver module can significantly simplify the design of the system. By combining the motor and driver electronics, engineers can reduce wiring complexity and minimize the installation errors.

These modules often come pre tuned and allow immediate operation without extensive setup. This makes them ideal for compact devices or prototypes of new devices.

However, integrated solutions are not always the best choice. They may limit flexibility if the application requires custom control or future upgrades.

DMKE addresses these needs by offering high-quality drivers that offer flexibility. This ensures that the engineers can select the setup that aligns with their application requirements without compromise.

Conclusion

Choosing the right motor driver transforms a BLDC motor from a simple component into a reliable and responsive system.

Ultimately, the ‘best’ driver will be the one that aligns with your motor as well as the operational environment and demands of your application.

For teams that are looking to simplify selection or verify compatibility, DMKE engineers are available to provide guidance and support.