How do you make the final decision whenever you go out to choose the right motor for your needs? Do you feel you make a well-calculated decision based on your budget? Or do you prefer going for an option that fulfils everything properly? Does the entire purchase process feel more like gambling?

The reality is, for many buyers, buying the right motor among a pool of options is a poorly calculated estimate. It is a process that often leads them to make the wrong choices. Buyers compare torque charts, watch different product videos, ask for reviews, and despite trying their best to get their hands on the best option, they often end up staying confused.

A common thing that confuses many buyers is the question of which motor can perform better within their budget. This simple question single-handedly impacts the overall purchase. This simple way of looking at a motor while keeping your budget at the back of your mind can decide whether you get a machine with the right speed, precision, and long-term ROIs.

When you pick the wrong option, you ultimately see the results a few days after the installation. There are missed steps, overheating, and stalling becoming common. Mostly, the tuning and maintenance costs for such mistaken systems are sky-high.

All these side effects of buying the wrong motor in haste are what bring us to differentiate between servo and stepper motors. This servo vs. stepper debate is more than just a technical one. Even when both these motors are capable of driving a setup forward with similar results, there is so much that differs between them.

Steppers offer simple and low-cost operation, while servos are made to perform high-duty tasks while also being a little heavy on your pocket. For buyers, the real challenge is understanding which of these options will shine better in their respective scenarios. If you are also one of those confused buyers, this guide is for you.

Below, we will be breaking down both servo motor vs. stepper motor technologies in a practical and real-world manner. This will help you choose the right option for your needs with confidence. Whether you need a motor for a CNC machine, conveyor belt, robot, or AGV, reading this article will help you see which of the above options can deliver better power without breaking your bank.

The Working of Servo Motor Vs Stepper Motor

Before we start discussing each of the options in the context of budget and performance, it is important to understand the basic working of a servo motor vs. a stepper motor.

Working Of Stepper Systems

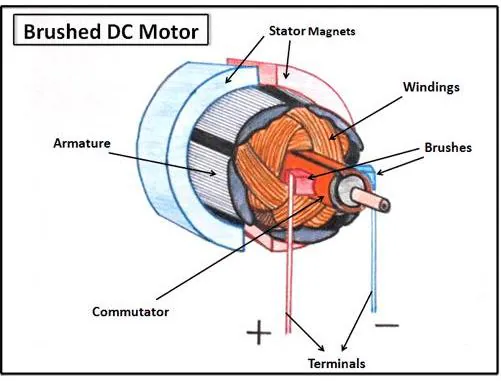

To begin with, a stepper motor moves in fixed, properly incremented steps. In these setups, every pulse that is sent by the controller rotates the windings in the shaft at a specific angle. This angle is maintained throughout the course of the setup’s operation. This gives the stepper motor its signature step-by-step and well-calculated working.

A stepper motor operates in an open-loop system. In such a system, the controller assumes the final position of the stepper motor, and there is no encoder to send back specific information for verification.

This absence of an encoder and the overall simplicity of the system are what make a stepper motor quite affordable and easy to install. Thanks to its straightforward internal design, there is hardly ever a need for electronic integration. These motors are capable of offering predictable motion for low- to medium-performance projects that don’t require a lot of precision.

While the simplicity keeps everything simple inside a stepper motor, and makes it easy to use and install, stepper motors also come with some limitations. At high speeds, these motors fail to deliver proper torque. Moreover, since there is no feedback, precision can sometimes be compromised.

However, for light loads and projects that don’t require a lot of accuracy and don’t depend too much on precision, this low-budget option is worth the investment.

Working Of Servo Systems

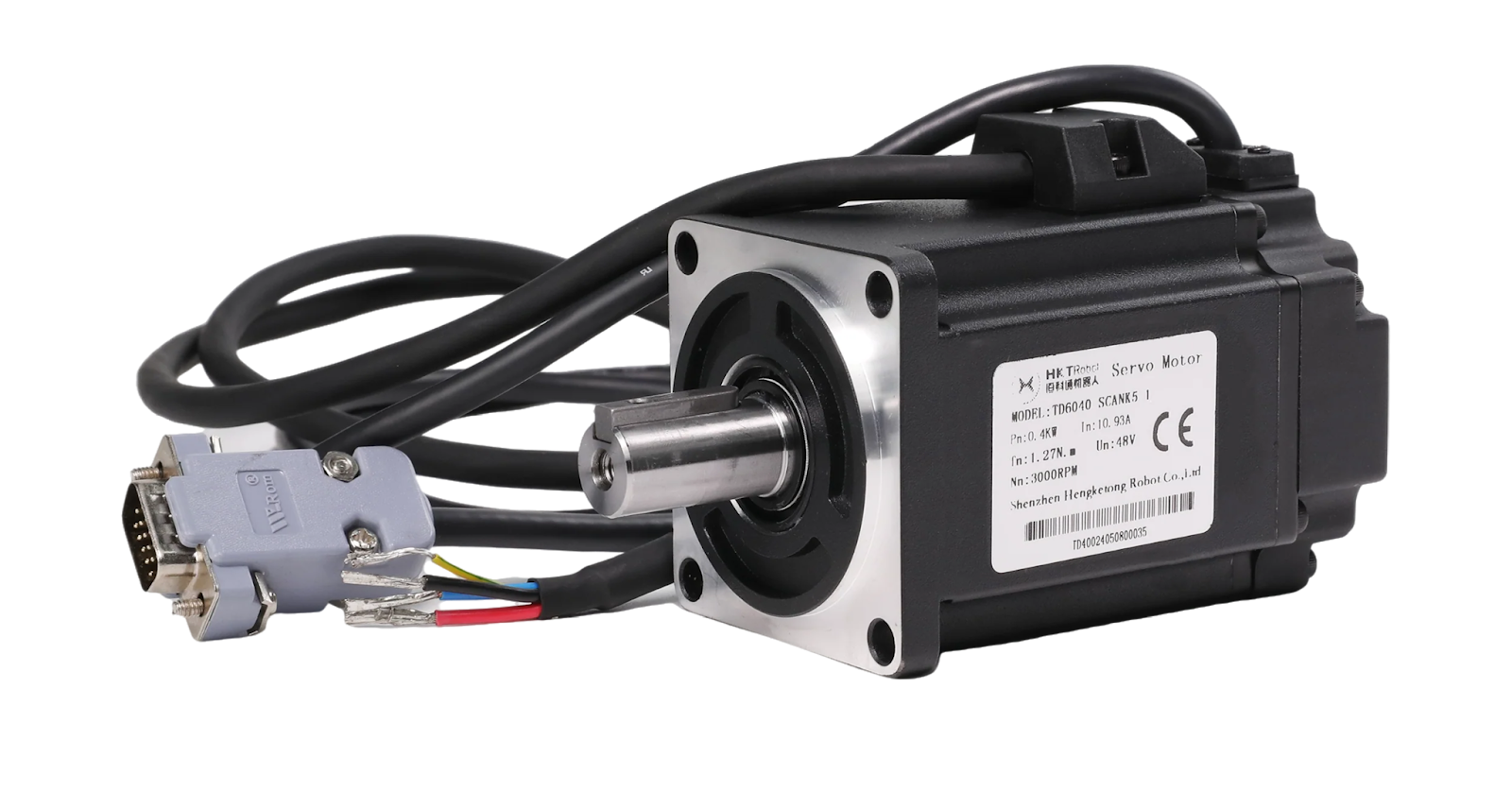

On the other hand, the working of servo setups is entirely based on intelligent feedback and corrections made on the basis of this feedback information. There is a built-in encoder in these setups that constantly reports back to the controller and helps make small real-time corrections to its functionality.

This closed-loop control enables the motor to perform highly precise functions with full control. In applications where servos are used, there is an instant correction of mistakes. Here, the torque is maintained properly across a wide variety of changing loads. Such motors also ensure minimal vibration and are hardly affected by external environment heat.

In short, where steppers work with assumptions, servo motors work with verified feedback. This makes the latter perfect for ideal, precise, and highly demanding applications and makes them capable of dynamic load handling.

All of this increases the pricing of servo setups. However, when looked at in the bigger picture, the performance per dollar of servos is highly significant and worth every penny.

Servo Motor Vs Stepper Motor Performance Comparison — Key Technical Differences

To further the discussion above, below we are going to discuss and differentiate between the servo motor and stepper motor in terms of their performance metrics, including torque, speed, acceleration, and a few more. So read on:

- Static and Dynamic Torque

Stepper motors excel at holding static torque, especially when the setup is working at a low speed. They are designed in a way that the rotors are naturally locked into discrete step positions. This makes them strong in static and low-speed situations. Therefore, steppers are ideal for CNC machines and basic 3D printers. However, at increasing speeds, the torque sharply drops, limiting their performance.

Servo solutions, on the other hand, excel at ensuring seamless torques even with changing speed curves. This makes them ideal for highly precise scenarios where the external load can change at any time.

- Acceleration and Speed

For applications and setups where quick movement, precise positioning, and rapid load changes are common, servos outperform the stepper motors in a noticeable way. They can reach high speeds and RPMs while staying stable.

On the other hand, while steppers are reliable, the reliability is limited only to low-speed operations where high acceleration and instant load changes are not common. Servos also respond faster to commands compared to the stepper appliances.

- Accuracy and Precision

Stepper solutions maintain accuracy through fixed steps, but their accuracy is only maintained while relying on assumptions. Under high speed, these assumptions are mostly incorrect, and hence, there is a disruption in the system’s working.

Servos, on the other hand, use encoders to verify position and accuracy constantly and make quick adjustments if anything is flawed. This makes them more precise and accurate compared to the stepper systems.

- Vibration, Noise, and Overall Smoothness

Steppers, as their name indicates, move in characteristic vibrational steps, especially when the speed goes a little bit above the low range. Hence, noise, mechanical wear, and vibration are common for these setups.

Servos, on the other hand, are built to be smooth and ensure noiseless operation with no vibration. Their ability to handle high speeds without vibrating is commendable, especially for longer-duration tasks.

Budget Comparison — What You Actually Pay For

Now that you have a basic idea of the differences in the performance of servo motor vs stepper motor, it’s good to look at how both of these can fit into your budget and what both have to offer in terms of the money that’s spent on them. While stepper solutions come with relatively cheaper price tags, the ROIs offered by servos often give them an advantage over the stepper solutions.

When you compare budgets, it is best to go past the upfront cost and also look at the deeper cost layers, like the cost of hardware, installation, and maintenance.

Speaking in terms of upfront price tags, a basic stepper solution mostly doesn’t come with any integrations and has a standard driver installed. Such a device is one of the most budget-friendly motorized solutions available right now throughout the world. In stepper solutions, there is no encoder and no advanced electronics, and hence their entry price is quite affordable.

On the other hand, a servo motor mostly comes with an efficient control system, tuning features, and a few integrations. All this makes them quite expensive compared to other simple motorized options.

In terms of installation costs, stepper solutions do not require any additional external help or professionals to ensure proper integration in the system. Servo solutions, on the other hand, might require a little tuning with proper parameter setups and coding, along with occasional calibration for their smooth installation.

The maintenance costs of stepper solutions are also considerable. Once the motor has been installed and operational for a considerable amount of time, it needs a little bit of maintenance to ensure its performance. Since stepper solutions vibrate heavily during high-speed or mid-speed working, their maintenance is often required because of occasional wear and tear.

Servo solutions, on the other hand, hardly ever require maintenance. Thanks to the quality components used inside them, and their ability to handle vibration and environmental constraints easily.

When you compare all the above costs, you realize that the lifetime cost of servo motors is considerably less compared to the stepper ones. Servo motors recover a large part of the money invested in them due to their high efficiency and minimal wear and tear. Their closed-loop system ensures that only as much power is drawn as is required and also reduces the loss of energy in terms of heat.

Stepper solutions, on the other hand, require constant current. It is common for them to overheat during intensive cycles. This not only wastes energy but also adds additional replacement and maintenance costs, thus making them an expensive choice for setups where they have to run consistently.

| Cost Factor | Stepper Motor | Servo Motor |

| Upfront Cost | Low | High |

| Installation | Simple, no tuning | Requires tuning |

| Maintenance | Minimal | Calibration may be needed |

| Energy Use | Higher (constant current) | Lower (load-based) |

| Long-Term Value | Good for low-budget setups | Best ROI for continuous/precision tasks |

Application-Based Comparison (What Fits Your Use Case?)

If you’re still not sure what to go for between the Servo and Stepper solutions, looking at how each of these can benefit or restrict you in terms of real-world usages can help ease the decision.

Speaking of Steppers, these setups are ideal for applications where you want to save your money and don’t have any strict precision and accuracy requirements. These systems include 3D printers, CNC router machines for hobbyists, desktop manufacturing tools, light home equipment and robots, along with some simple picking and placement systems.

Steppers offer predictable movement along with easy installation and have a low initial price. All such features make them a perfect choice for educational projects, school and college laboratories, and other low-duty-cycle setups.

Servos, on the other hand, are dominant in high-demand environments where continuous operation and flawless accuracy are mandatory. The common places for servos include industrial automation lines, heavy-duty robotic arms, AGVs, AMRs, packaging lines, textile industries, and any other system where high-load handling is habitual.

The closed-loop designs of servos make them ideal for setups where high torque and RPM are required with smoothness, precision, and low noise and vibration.

In real-world situations, Steppers tend to fail whenever they are required to hold their torque at high speeds or when they are exposed to heavy loads. In such situations, they may skip their steps and lose their precision since they are being pushed beyond their comfort zone. They will also generate heat and lose most of their energy in the form of heat and noise during long operations. This leads to the ultimate failure of the setup.

Servos, on the other hand, maintain torque across different speed curves and are capable of dealing with varying loads. They stay cooler and deliver noiseless and vibration-free performance, no matter how long their duty cycles are.

Below is a table that gives you a detailed at-a-glance comparison of Seteppers and Servos across different parameters.

| Parameter | Stepper Motor | Servo Motor |

| Torque at Low Speed | Very strong | Strong |

| Torque at High Speed | Drops significantly | Stays stable |

| Accuracy | Good | Excellent |

| Speed | Moderate | Very high |

| Cost | Low | High |

| Efficiency | Lower (constant current) | Higher (load-based) |

| Noise | Noticeable | Quiet |

| Heat Generation | Higher | Lower |

| Load Handling | Limited | Excellent |

| Control Type | Open-loop | Closed-loop (with encoder) |

| Maintenance | Minimal | Requires calibration |

| Best Use | Low-cost machinery, 3D printers, DIY CNC | Industrial automation, robotics, heavy loads |

Final Verdict: Which Is A Better Choice In Your Budget

By now, we are sure that you have understood how to make the right motor choice within your budget. To make sure that you are taking the right step while making a purchase, it is important to understand that selecting the right device is not just about looking at some numerical data on a spec sheet.

It is rather about looking at how all these things align with your expectations and whether or not the motor matches your purpose of using it. A well-chosen motor is one that comes with reduced long-term costs while also having an upfront cost that you can easily afford. At the same time, it must also be able to handle the task at hand with minimal wear and tear and as few headaches as possible.

A stepper motor is a smarter choice for people who are shopping on a budget. It is also ideal to invest in when the application requires predictable motions and won’t be facing heavy loads. If your accuracy demands are not strict, and if the duty cycles of your application come with breaks and intervals, go for a stepper.

Investing in a servo solution pays off in the long term for applications that have long duty cycles. It is also ideal to be used where speed, precision, and continuous performance are almost uncompromisable. For servos, the upfront cost is quite high. However, these solutions often have little lifetime expenses because they minimize downtime, run for longer intervals, and waste as little energy as possible.

Let DMKE Help You Make The Right Choice

Choosing the right option between a servo motor vs stepper motor is a step that must be taken with great care. It is not something that you can ace simply by playing a guessing game.

Steppers excel because of their low budget, light load, and step-by-step work style. They are also perfect for low-budget buyers who want a motor to tackle light loads and follow a moderate speed pattern in their work. These motor steppers are quite reliable and easy to install, and hence perfect for small-scale automation. Servos, on the other hand, shine where precision and speed are a priority and budget isn’t what matters the most.

Ultimately, the right choice between a servo motor and a stepper motor is entirely dependent on your specific usage, budget, requirements, and expectations from your purchase.

At DMKE, our experts can help you figure out the exact solution for your specific needs that delivers promising results. All our motorized solutions, from steppers to servos, are made with high-quality components and undergo a vigorous 8-step verification before sale. This way, we make sure that each and every solution that we offer can deliver up to the mark.

Visit our website and connect with our experts today to get your hands on our ready-made motorized solutions, or simply start conversations for a custom motor setup as per your needs.