In the modern-day world, automation is not just about simple motion. Rather, it now requires the ultimate form of precision, repeatability, responsiveness, and absolute control, despite continuously changing external conditions. Modern production systems are required to be faster, smarter, and more interconnected than ever before, and this has limited the use of conventional motor technologies in such systems.

Thankfully, AC servo motors have stepped in at the right time. These now continue to dominate automation systems throughout the world. AC servo motors have established themselves as the most preferred choice for automation-related environments because of their ability to deliver results. These motors are capable of staying consistent despite external loads and immensely changing environments.

Unlike classical motors that operate primarily in an open-loop system, AC servo motor solutions are designed to work in closed-loop systems. This means these systems remain aware of their own performance and are capable of making real-time corrections to their operation. This closed-loop system also allows servo solutions to have precise control over position, speed, and torque, regardless of variations in external load and the high dynamic demands of the overall setup.

For engineers and industry owners who want to build modern automated systems based on accuracy, reliability, proper synchronisation, and consistency, using servo motors helps enhance overall productivity and quality, while also providing the level of control that is extremely essential for the proper functioning of the system.

Many people ask why AC servo motors are currently dominating modern automation systems to such an extent that no other motor remains relevant for automation. The answer is not in a single advantage offered by servo solutions. Rather, these motors provide a combination of performance, repeatability, reliability, and longevity that makes them both efficient and the most preferred solution across almost all industries.

Whether it is high-speed production lines, AGVs, robotic arms, or simple CNC machinery and packaging systems, servo solutions help manufacturers achieve perfect tolerances while ensuring fast working cycles and offering great operational flexibility. On the other hand, advancements in power electronics, improvements in feedback devices, and the development of digital controllers have further enhanced servo motor efficiency. This means that while servo motors continue to serve the automation industry, they are also continuously being improved to offer even more capabilities and push technological boundaries.

Below, we will discuss in detail what makes servomotor AC so important and dominant in modern automation systems. This will be followed by a detailed comparison of servo solutions with other motors, highlighting the shortcomings those motors exhibit when used in automation. So, read on to discover what makes AC servo motors a foundational technology in today’s automated industrial systems.

Core Reasons Behind the Dominance of AC Servo Motors

Below, we will discuss in detail, one by one, the reasons that make AC servo motor solutions such an important backbone of modern automatisation industrielle systems. So, read on.

1. High-Precision Positioning And The Ability To Offer Repeatable Motion

Modern automation is all about motion accuracy measured in microns and milliseconds. Thankfully, AC servo motor solutions are capable of delivering precise positioning due to their high-resolution feedback devices, such as encoders and resolvers. These allow exact motion control across repeated cycles.

This high level of working accuracy and repeat ability ensures that the resulting product quality from an automated setup is absolutely 10 out of 10. Such repeatability also reduces variations in the process and enables tighter tolerances in high-speed manufacturing and motion-related tasks. This level of precision and repeatability makes AC servo motors ideal for environments where even minor deviations can lead to downtime due to rework and rejections.

2. Closed-Loop Feedback System

The most powerful advantage of AC servo solutions is their ability to monitor feedback through a closed-loop system. This closed-loop feedback architecture enables these motors to continuously and consistently monitor their operating speed, torque, and position, while automatically compensating for changes in the external environment. It also allows the motor to maintain proper performance in real time by applying corrections wherever required.

The closed-loop feedback system of a high-quality AC servomoteur ensures stable performance despite fluctuations in operating conditions, making these motors ideal for applications where variable load acceleration and intermittent resistance are common.

3. Superior Torque Control Across Different Speeds

Servomotor ACs are capable of delivering controlled and smooth torque output across a wide speed range, including zero-speed holding conditions. Unlike conventional motor systems that lose accuracy and control at low speeds, servo motors maintain full torque precision with smooth, controlled starts and stops, even during low-speed operations.

This capability makes AC servomoteurs critical for automation tasks such as indexing, assembly operations, and robotic motion.

4. Quick Response With Motional Stability

Automation processes often require quick acceleration, deceleration, and frequent directional changes. The components involved in these processes must handle sudden shifts in direction and speed. In most modern automation systems, the key requirement is that, despite all these changing conditions, directions, and speeds, there must be no vibration or instability in the overall system.

Thankfully, AC servo motor solutions are capable of meeting these demands. These systems are engineered for fast dynamic responsiveness, allowing them to react instantly to changing control commands. This high responsiveness, without glitches or jitter, improves overall cycle timing while maintaining motion stability and smoothness in the automation process, regardless of how aggressive the speed transitions are.

5. High Power Density In A Compact Body

AC servo motors deliver high couple and power output, which can seem almost unbelievable given their small physical size. This high power density allows engineers to integrate these motors into compact and portable system designs without compromising speed or performance.

The smaller and more compact size of AC servo motors also reduces overall system inertia, which further enhances dynamic response and improves overall system efficiency without making the setup bulky or space-consuming.

6. Energy Efficiency

Energy efficiency ratings are often quoted under ideal operating conditions. However, AC servos are notable for maintaining high efficiency across varying loads and speeds, even in continuously changing environments. Their closed-loop control system minimises energy wastage by supplying only the torque required at any given moment.

Over time, this intelligent torque delivery and energy efficiency translate into lower overall energy consumption, reduced operational costs, and improved performance, making these ideal for multi-axis and multi-dimensional automation systems.

7. Seamless Integration With PLCs and Industrial Networks

Modern AC servo solutions are designed for seamless integration with PLCs, HMIs, and other industrial communication networks. In most cases, no additional hardware integration or complex coding is required to enable connectivity.

This high level of adaptability allows engineers to build systems with centralised control, real-time monitoring, and precise synchronisation, even when operating across multiple axes. Such integration is critical for smart factories, where coordination and data-driven optimisation are key drivers of performance and compatibility.

8. Reduced Maintenance With High System Reliability

AC servos require minimal mechanical maintenance due to the absence of brushes, which eliminates friction-related wear. As a result, overall mechanical degradation is significantly reduced.

In addition, AC servo motors are equipped with advanced diagnostic and condition-monitoring capabilities that enhance reliability. These systems enable self-correction and predictive maintenance by identifying potential performance issues before they escalate into failures. This proactive approach minimises system downtime, extends service life, and makes AC servos an essential component of modern automation systems.

9. Scalability For Diverse Applications

AC servo solutions are capable of operating across a wide range of applications, from simple pick-and-place systems to complex multi-axis robotic automation platforms. These motors scale effectively across different automation setups and deliver seamless performance exactly where and when required.

Their adaptable nature allows manufacturers and engineers to standardise motion-control solutions while still meeting the varying performance requirements of different automation systems.

10. Advanced Drive Intelligence And Auto-Tuning Capability

The closed-loop system used in modern AC servos enables automatic performance tuning based on real-time feedback received from encoders. In addition, modern servo drives are equipped with intelligent algorithms that simplify system setup and optimisation.

The auto-tuning capability allows these motors to automatically adjust control parameters according to system behaviour and characteristics. As a result, commissioning time is significantly reduced without compromising performance. Engineers also do not need to perform extensive manual calibration for the motors to meet specific operational requirements.

Overall, these intelligent servomotor AC solutions enable faster deployment and smoother system commissioning while delivering consistent and reliable results across multiple operating cycles.

Where AC Servos Deliver the Greatest Impact?

By now, you must have understood that AC servo solutions are capable of delivering the highest value in all automation-related environments. These are ideal equipment to have, especially in places where motion accuracy, dynamic control, coordination, and overall system synchronisation are extremely important and directly determine the productivity and output of the overall setup.

The impact of AC servos becomes most obvious in setups where precision, repeatability, and responsive motion are highly demanded despite continuously changing external operating conditions.

Dans robotics and other motion systems requiring articulated control, AC servos enable proper multi-axis coordination while ensuring smooth trajectory control and providing rapid response to command inputs. Robotic arms, pick-and-place belts, pick-and-place systems, and collaborative robots rely heavily on servos to achieve accurate positioning while ensuring high cycle speeds and safe, reliable operation.

CNC machines and other precision machining systems are another common area where AC servos are indispensable. In such systems, exact positioning and smooth interpolation are required across different axes to maintain dimensional accuracy and overall surface finish. Here, these motorised systems ensure controlled acceleration, deceleration, and synchronisation, enabling higher-precision cutting at higher spindle speeds.

Material handling systems and automated assembly lines are also common areas where the role of AC servos is non-negotiable. These systems benefit from the ability of servos to manage varying loads and dynamic motion profiles. Common examples include indexing tables, automated fastening systems, and electronic assembly lines, where controlled motion with minimal jitter and vibration is essential.

In packaging and labelling lines, AC servos help ensure critical timing and synchronisation requirements. They allow precise control of conveyors, feeders, cutters, sealers, and related equipment. The fast response and repeatability of these systems help maintain consistent throughput while accommodating frequent operational changes.

In printing, converting, and textile-related machinery, servos provide proper tension control along with registration accuracy and synchronised motion. They ensure uniform product quality while supporting high-speed operation without slippage or instability.

In addition, AC servos play a very important role in process automation and synchronised multi-axis systems, where multiple systems must operate together in a precisely coordinated manner. Their integration with PLCs and industrial networks ensures centralised control, real-time feedback, and adaptive optimisation across large systems and extensive production lines.

Overall, in all these applications, the defining factor is not just motion, but the control and efficiency of that motion. This specifically highlights the ability of AC servo motors to accurately, responsively, and reliably translate electrical input into productive output, reduce waste, and deliver scalable performance.

AC Servo Motors Vs Other Motion Technologies

While multiple motion technologies are used in automation, their suitability varies greatly. This suitability depends on precision, responsiveness, and system complexity. AC servos set themselves apart by offering a balanced combination of control accuracy, dynamic performance, and integration flexibility. Unfortunately, many other alternatives can’t yet achieve this blend of features.

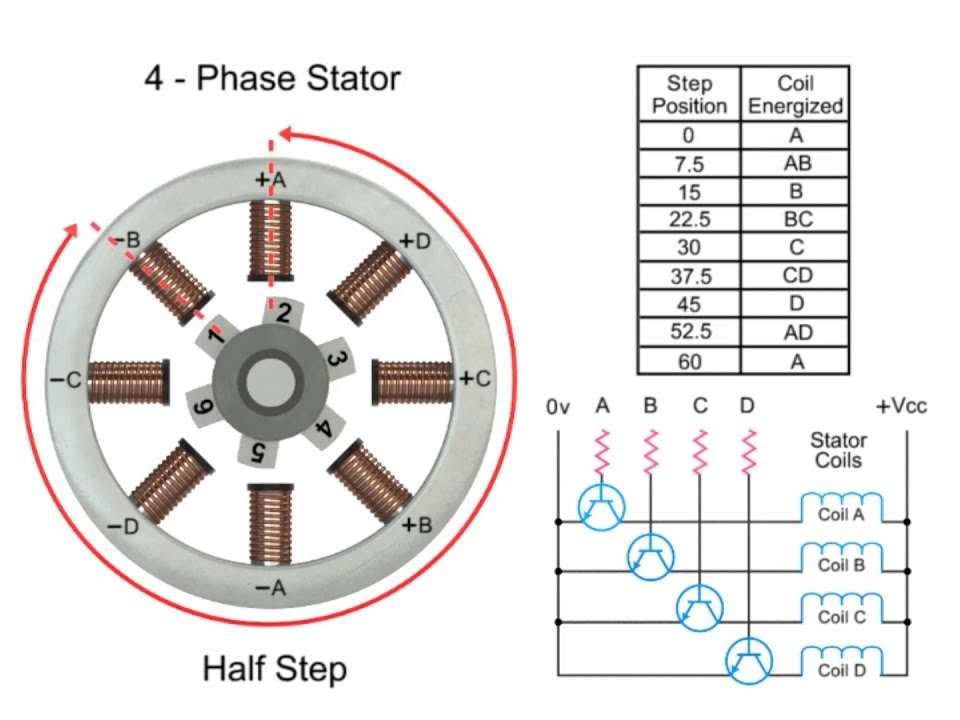

Firstly, we’ve Stepper solutions that are commonly used in low-cost or low-complexity positioning systems. These are used in systems where they can operate without feedback in most configurations. As a result, these units show a limited ability in terms of being able to compensate for load variations. Under higher speeds or unforeseen load changes, stepper solutions can lose steps without detection. This makes them a little less suitable for applications requiring high reliability, precision, and dynamic motion control, something only servos can best provide.

Another common modern motorised setup is found in the form of VFD-driven induction units. These units excel in several applications, especially those that are focused on speed control and continuous operation. However, they fail when precise positioning is something that is non-negotiable. While variable frequency drives provide adjustable speed, they lack real-time positional feedback.

The VFD-driven induction setups also can’t ensure fine torque control that is otherwise very commonly and easily offered by servo systems. As a result, induction motors are better suited for pumps, fans, and conveyors where exact motion control is not critical.

Next, we have the modern Hydraulic and pneumatic systems. These systems are capable of delivering high force output. They also show great ability and are quite effective in heavy-duty environments. However, they introduce limitations in accuracy, energy efficiency, and controllability. Fluid leakage, pressure fluctuations, and higher maintenance requirements make them less ideal for modern automation systems that prioritise precision, cleanliness, and digital integration.

In contrast, AC servos combine closed-loop control, high dynamic response, and seamless digital integration, enabling precise motion control across a wide range of automation tasks. Their ability to adapt to changing loads, synchronise multiple axes, and integrate with intelligent control systems positions them as the preferred choice for modern, data-driven automation environments.

Here is a brief yet insightful comparison of some common motor types with Servomotor AC solutions that can help you see what makes the latter better:

| Criteria | AC Servos | Steppers | VFD-Driven Induction Units | Hydraulic / Pneumatic Systems |

| Control Method | Closed-loop with real-time feedback | Mostly open-loop | Open-loop speed control | Pressure / flow-based control |

| Position Accuracy | Very high, precise positioning | Moderate, step-based | Low, not position-focused | Low to moderate |

| Load Compensation | Automatic, real-time adjustment | Limited, risk of step loss | Poor under varying loads | Inconsistent due to pressure changes |

| Speed Range Control | Excellent across wide speed range | Limited at high speeds | Good for continuous speeds | Limited fine control |

| Dynamic Response | Fast acceleration and deceleration | Modéré | Slow to moderate | Slow and less predictable |

| Torque Control | Precise torque at all speeds | Drops at higher speeds | Limited torque accuracy | High force but poor precision |

| Energy Efficiency | High under real operating conditions | Modéré | Efficient for constant loads | Generally low efficiency |

| System Integration | Seamless with PLCs & networks | Limited integration | Basic integration | Complex and indirect |

| Maintenance Requirements | Faible | Low to moderate | Faible | High (leaks, wear, fluid issues) |

| Scalability & Flexibility | Highly scalable, multi-axis ready | Limited scalability | Limited to speed control | Poor scalability |

| Typical Use Cases | Robotics, CNC, packaging, automation | Low-cost positioning | Pumps, fans, conveyors | Heavy force applications |

Get Reliable Servomotor ACs For Your Needs From DMKE Today!

À DMKE, we are offering ready-made and custom motorised solutions to cater to all your industrial automation needs. All our solutions undergo rigorous 8-step testing before being made available for sale. This makes our offerings undeniably reliable, offering unparalleled performance under all conditions.

Visitez notre site Web et contactez-nous dès aujourd'hui to get your hands on the most accurate, reliable, and impactful servos that deliver beyond your expectations. Not sure which servo with work best for your system? Let our experts help you with detailed consultations and expert guidance available at every step of your purchase experience.