Contrôleur de moteur BLDC

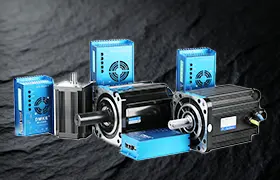

- DMKE

- Moteur à courant continu sans balais

- Contrôleur de moteur BLDC

The BLDC motor controller is the indispensable brain of the motor, precisely orchestrating power delivery to achieve efficient, reliable, and intelligent motion control.

About BLDC Motor Controller

The BLDC Motor Controller is the indispensable brain of any Brushless DC Motor, essential for its operation. As a true brushless electronic speed controller, it transforms power into precisely controlled motion, unlocking superior efficiency and performance. Furthermore, with advanced features like RS485 communication, it enables centralized command, real-time monitoring, and smart control for seamless integration into sophisticated automated systems.

By delivering a combination of essential control, seamless integration, and unwavering protection, BLDC motor controllers are more than just accessories—they are the vital command centers that define the performance and intelligence of modern motion systems.

| Contrôleur de moteur BLDC | ||||

| Plage de courant nominal (A) | 3 A à 300 A | |||

| Tension nominale (V) | 12 V à 310 V selon le type de moteur | |||

| Mode de communication sélectionnable | RS485, RS232 | |||

| Plage de réglage de la vitesse | 300 à 3000 tr/min | |||

| Informations nécessaires | Puissance nominale et tension du moteur, température ambiante température, méthode de communication | |||

The Intelligent Nerve Center-BLDC Motor Controllers

Industrial Automation & Robotics

Acting as the “central nervous system” for automated arms and conveyors, BLDC controllers receive commands via interfaces like RS485. They execute flawless sequences for start, stop, and directional changes (forward/reverse), enabling complex, repetitive tasks with unwavering consistency.

CNC Machines & Servo Drives

For precision machining, accuracy is non-negotiable. BLDC controllers achieve and maintain exact motor speeds with remarkable stability, ensuring consistent results for cutting, milling, and positioning down to the micron.

Why is a dedicated controller an indispensable partner for every BLDC motor?

Unlocking Core Functionality

A BLDC motor cannot run on simple DC power. The controller is the essential device that provides the sequenced, three-phase power necessary for rotation, enabling fundamental operations like start, stop, forward, and reverse.

Intelligent Communication & Integration

With standard communication protocols like RS485, CAN, or PWM, controllers seamlessly integrate into complex systems. They allow for centralized command, real-time data monitoring, and sophisticated control strategies from a host computer or PLC.

Precise Speed & Torque Control

BLDC controllers provide exact digital command over motor speed and torque. They respond instantly to input signals, delivering the precise power required for the application, which translates to accurate motion, stable operation, and high overall system efficiency.

Enhanced Protection & Reliability

Designed for robust operation, controllers incorporate vital protection features like over-current, over-voltage, and over-temperature safeguards. This dramatically extends the motor's lifespan and ensures system reliability, preventing downtime in critical applications.

Pourquoi DMKE ?

Production interne avec plus de 150 employés

Large spectre de puissance : moteurs CC sans balais de 5 W à 25 kW

Plus de 16 ans d'expertise dans l'industrie automobile et de connaissances en matière d'applications

Systèmes intégrés de moteurs et d'entraînements pour une responsabilité sans faille

Assistance gratuite d'experts en ingénierie avant-vente et en sélection

Certification ISO9001, CE et RoHS Assurance qualité

Plus de 40 brevets et plus de 20 ingénieurs R&D pour des solutions personnalisées

Assistance technique après-vente professionnelle et réactive