Avez-vous déjà été confronté à des pannes d'alimentation, à une durée de vie réduite ou à des coûts imprévus parce que le moteur n'était pas adapté ? Il s'agit d'un problème courant dans les systèmes industriels, qui trouve généralement son origine dans un mauvais choix de moteur.

Il est indéniable qu'un moteur à courant continu permet de faire bouger les choses, mais il favorise également la productivité, l'efficacité et la fiabilité à long terme. Par conséquent, lorsque le moteur n'est pas adapté à la tâche à accomplir, cela entraîne un gaspillage d'énergie et une accumulation de chaleur. Ces deux problèmes sont ensuite suivis de problèmes mécaniques. Il en résulte des temps d'arrêt et des coûts de maintenance plus élevés.

C'est pourquoi il est important de comprendre comment choisir le modèle adapté à votre configuration.

DMKE se concentre sur sans balais et servomoteur Une technologie moteur conçue pour les environnements industriels où la fiabilité et la précision sont essentielles.

Dans ce guide, nous examinerons les principaux types de moteurs à courant continu et vous présenterons des étapes pratiques pour vous aider à choisir le modèle adapté à votre application. Si vous suivez ces étapes, votre équipement aura plus de chances de fonctionner plus longtemps, plus facilement et plus efficacement.

Pourquoi le moteur à courant continu est-il le choix privilégié pour les équipements d'automatisation ?

En matière d'automatisation, la précision et le contrôle sont essentiels. Les machines doivent réagir rapidement, s'arrêter au bon moment et gérer sans difficulté les variations de charge. C'est là que les moteurs à courant continu excellent.

Examinons quelques raisons pour lesquelles les moteurs à courant continu restent le choix privilégié pour les systèmes d'automatisation dans tous les secteurs industriels.

Contrôle rapide et précis des mouvements

L'automatisation dépend en grande partie de la rapidité et de la précision avec lesquelles un système réagit aux commandes.

Un moteur à courant continu réagit presque instantanément aux commandes. Cette caractéristique le rend idéal pour les équipements qui doivent démarrer, s'arrêter ou changer de direction avec précision. C'est pourquoi les moteurs à courant continu sont largement utilisés dans les bras robotiques, les machines de prélèvement et de placement et les systèmes de convoyage.

Régulation fluide du couple et de la vitesse

L'un des principaux avantages des moteurs à courant continu réside dans leur contrôle fluide de la vitesse. Comme ils fonctionnent à courant continu, ils permettent d'ajuster facilement et précisément le couple et la vitesse sans circuit complexe.

Cela permet aux ingénieurs d'adapter plus facilement les performances des moteurs aux besoins spécifiques de la production. L'équilibre entre contrôle et simplicité est ce qui maintient les moteurs à courant continu au cœur de l'automatisation industrielle.

Efficacité énergétique

Dans les usines et les entreprises qui accordent une grande importance aux principes ESG et/ou souhaitent réduire leurs coûts énergétiques, l'efficacité énergétique revêt une importance capitale.

Un moteur à courant continu convertit une plus grande partie de l'énergie fournie en énergie mécanique et gaspille moins d'énergie sous forme de chaleur. Cela permet non seulement de réduire les coûts d'électricité, mais aussi de maintenir des températures de fonctionnement plus basses, ce qui est bénéfique pour prolonger la durée de vie du moteur et des composants environnants.

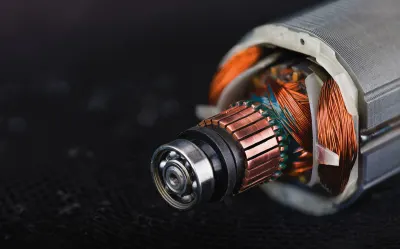

Types de moteurs à courant continu

Tous les moteurs à courant continu ne sont pas identiques. Les différences en matière de conception, de construction et de méthode de commande font qu'un moteur est mieux adapté à une tâche donnée qu'un autre.

Comprenons donc ensemble les différents types. Lorsque vous lisez des informations sur ces types de moteurs à courant continu, il est conseillé d'analyser et de noter ce qui semble convenir à votre situation.

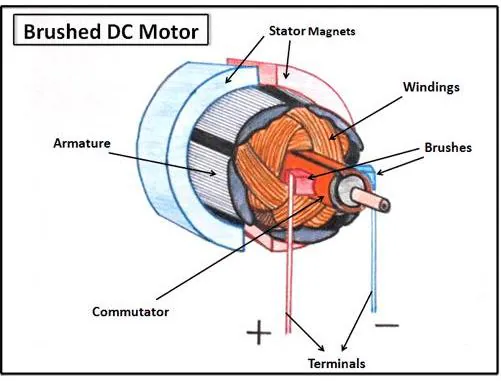

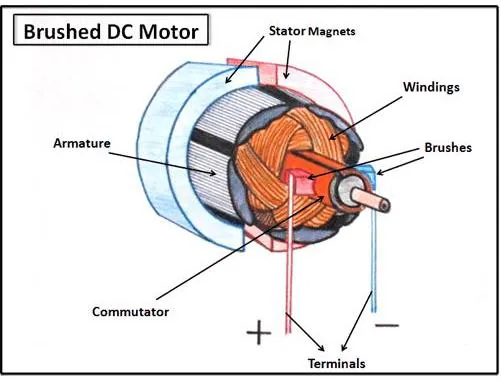

Moteurs à courant continu à balais : simples, abordables et faciles à contrôler

Les moteurs à balais sont les moteurs électriques à courant continu les plus anciens et les plus simples. Ils utilisent des balais et un commutateur pour gérer la commutation électrique qui permet au rotor de tourner.

Avantages :

- Commande simple

- Faible coût initial

- Couple de démarrage élevé, ce qui le rend idéal pour la manutention de charges de base.

Inconvénients :

- Les brosses s'usent avec le temps, ce qui nécessite un entretien régulier.

- La friction génère de la chaleur, du bruit électrique et une légère baisse d'efficacité.

- Durée de vie plus courte par rapport aux modèles sans balais

En général, les moteurs à balais sont utilisés dans les équipements légers et peu coûteux. Cela comprend les pompes, les convoyeurs, les petits outils ou les systèmes d'automatisation simples.

Conseil pour l'approvisionnement : Si votre système fonctionne de manière intermittente et que votre budget est serré, un moteur à courant continu à balais peut être un choix pratique. Mais pour un fonctionnement 24 heures sur 24, 7 jours sur 7, ou un contrôle précis, envisagez de passer à la technologie sans balais.

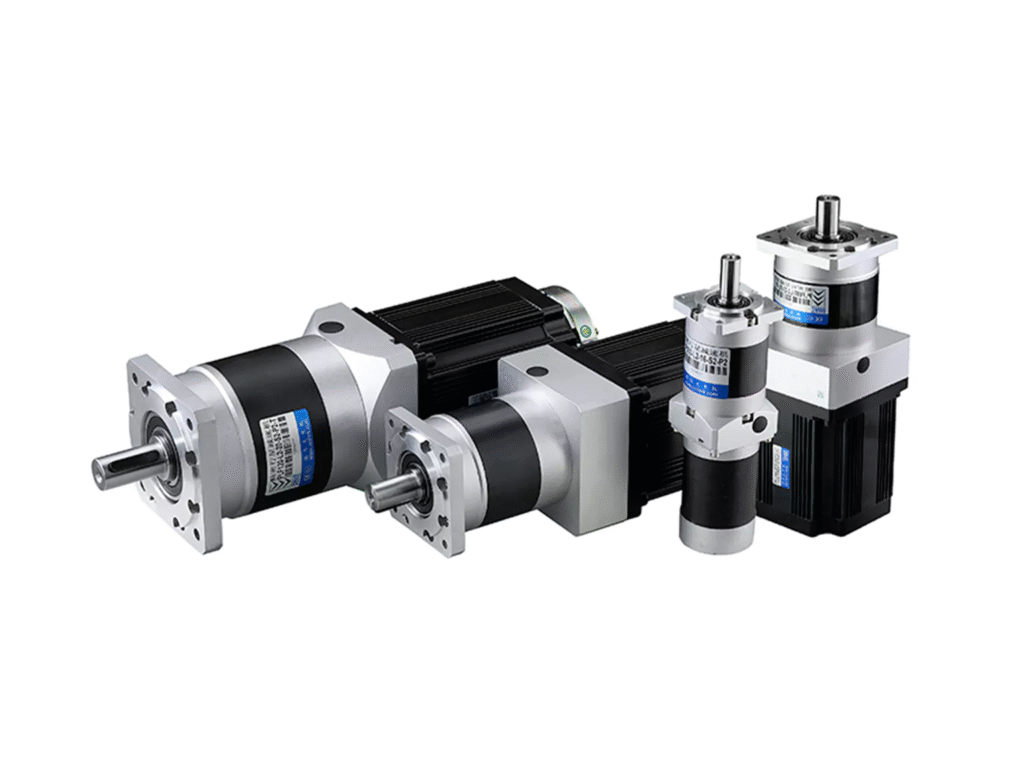

Moteurs à courant continu sans balais

Moteurs sans balais reprenez la même idée, mais supprimez les points de contact physiques.

Ici, des circuits électroniques sont utilisés pour gérer la commutation à la place des balais et du commutateur. Cela élimine les principales pièces d'usure et prolonge la durée de vie du moteur.

La fiabilité et la précision sont très importantes dans la robotique, les appareils médicaux, les drones et les systèmes d'automatisation industrielle, c'est pourquoi les moteurs à courant continu sans balais ou BLDC sont souvent utilisés dans ces domaines.

Avantages :

- Haute efficacité et contrôle fluide de la vitesse

- Longue durée de vie avec peu d'entretien

- Fonctionnement silencieux et bruit électrique minimal

Inconvénients :

- Coût initial plus élevé

- Nécessite un contrôleur pour fonctionner

Conseil pour l'approvisionnement : Lors de la conception d'équipements fonctionnant en continu ou nécessitant un contrôle fluide de la vitesse variable, un moteur DLC sans balais vaut l'investissement supplémentaire.

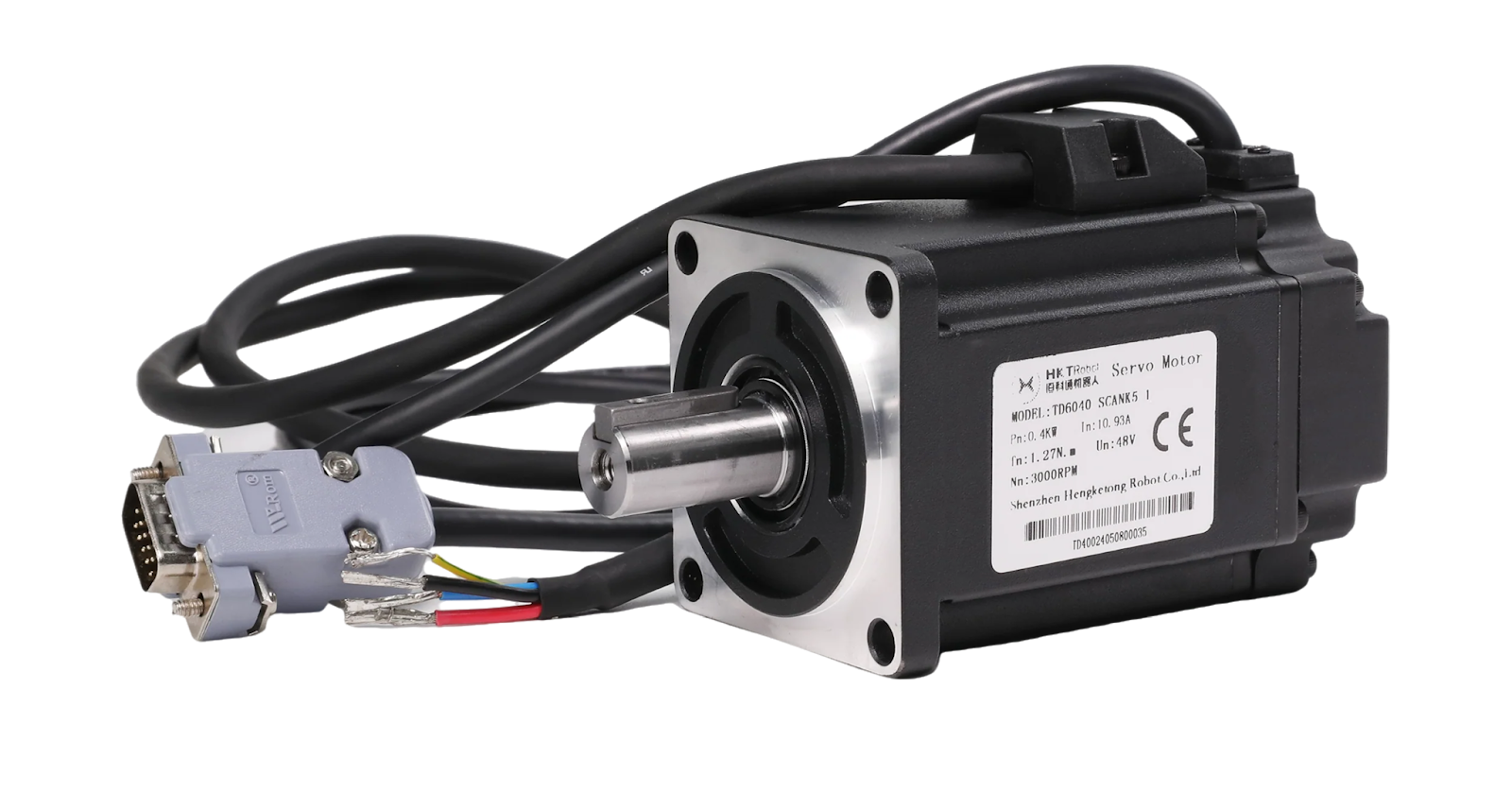

Servomoteurs

Servomoteurs sont conçus pour le contrôle.

Ils sont conçus pour se déplacer vers une position précise. Maintenir cette position. Et répéter le même mouvement avec précision.

À l'intérieur d'un système asservi, vous trouverez un moteur ainsi que des capteurs et une boucle de rétroaction qui vérifie en permanence la position, la vitesse et le couple.

Servo motors come in both: DC and AC types. However, DC servo motors are often preferred for smaller or mid range systems. It’s good for systems that require smooth and fast response like robotic arms as well as automated packaging lines.

Avantages :

- Extremely accurate positioning

- Fast response to control signals

- Stable performance even under changing loads

Inconvénients :

- Higher cost and more complex setup

- Requires a control system for proper operation

Procument Tip: When choosing a servo motor, consider your required torque, speed range, and control feedback.

Coreless and slotless designs

In some high-performance applications, traditional motor construction isn’t just enough. That’s where coreless and slotless designs come in.

Instead of a heavy iron core, these motors use a lighter structure. It reduces inertia and allows a fast acceleration.

Coreless motors are used in equipment like medical tools or aerospace mechanisms.

While they tend to cost more, their performance benefits can be significant. This is especially useful if you need accuracy and speed with minimal weight.

Avantages :

- Quick response and acceleration

- High efficiency with low vibration

- Lightweight and compact (especially for miniature motors)

Inconvénients :

- More expensive than traditional and larger DC motors

- Lower heat capacity

Conseil pour l'approvisionnement : Coreless motors are ideal when every gram counts or when motion must be incredibly smooth. For standard automation though, a brushless or servo motor usually provides a better cost to performance balance.

Key factors to consider when choosing a DC motor

Speed and voltage are just the starting points that you need to consider when choosing a DC motor.

The right motor will fit those needs without running too close to its limits or wasting energy. Below are the main things to look at before deciding which motor fits your job.

1. Voltage and power requirements

Start with the basics. A DC motor must match the power system it’s connected to. Most industrial setups use standard voltages like 12V, 24V, or 48V, but it’s important to confirm what your system can actually supply.

If the motor’s rated volts are too low, it may run hot or wear out early. If it’s too high, it won’t reach full performance.

Power rating is another key number. It tells you how much work the motor can do without overheating. Always look at both the rated power and electric current draw. If your system’s power supply isn’t stable or has volts drops, that can affect how smoothly the motor runs.

2. Speed and torque

Every motor has a torque-speed curve that shows how it performs under load. Torque is the turning force, and speed is how fast the motor shaft spins. The two always balance each other. When torque goes up, speed goes down, and vice versa.

It’s important to understand what your industrial machinery needs. For example, conveyors and lifts need high torque at lower speeds. Fans or blowers usually need higher speed but lighter torque.

Also, check for continuous torque (the torque it can handle all the time) and peak torque (short bursts). A good match means the motor can handle the normal workload without overheating or stalling.

3. Efficiency and thermal performance

Efficiency matters because wasted energy turns into heat. In an industrial environment, that heat builds up fast. A more efficient motor runs cooler, uses less electricity, and lasts longer.

Thermal design is often overlooked but critical. Motors that can dissipate heat properly perform more consistently. Some come with built-in fans or external cooling options. When space is tight or airflow is limited, this becomes even more important.

4. Load characteristics

Think about what kind of load the motor will drive. Is it constant, like a conveyor belt running at steady speed? Or does it often change, like a robot arm or press machine that starts and stops throughout the day?

For steady loads, a basic brushed or brushless motor usually works fine. For changing or high-inertia loads, you may need a motor that can handle frequent acceleration and deceleration. Matching the motor’s inertia to the driven load helps avoid vibration, overshoot, and mechanical energy wear.

5. Control requirements

How you plan to control the motor affects the type you choose. If the system just needs simple on-off or fixed-speed operation, a brushed motor with basic control may be enough. But if you need variable speed, torque control, or precise positioning, a brushless or servo motor makes more sense.

Modern automation often uses closed-loop control systems with sensors or encoders that provide feedback. These let the controller adjust performance in real time, improving accuracy and response. Check whether your motor can integrate with your PLC or driver setup before finalizing a choice.

6. Environmental Conditions

Motors don’t operate in perfect lab conditions. Dust, moisture, temperature, and vibration all affect performance. Always check the IP rating, which tells you how well the motor is sealed against particles and liquids.

If the motor will be used outdoors, near water, or in a factory with oil mist or metal dust, go for a sealed or coated version. Also consider the temperature range. Extreme heat or cold can change how insulation and bearings behave.

In harsh environments, paying a little more for protection up front saves on replacement and downtime later.

7. Maintenance and lifespan

Every type of motor has its own maintenance pattern. Brushed motors need brush replacement and periodic cleaning, while brushless motors run for years with almost no service.

When comparing models, think about the total cost over time, not just the purchase price. A cheaper motor that needs frequent maintenance can end up costing more than a premium one that runs longer without attention.

If your goal is to keep production running with minimal downtime, a brushless DC or servo motor is usually the better long-term investment. Many users find that the higher initial cost pays for itself in reduced maintenance and energy savings.

DC motor applications across industries

DC motors are used in nearly every field where motion or precision control is needed. Their balance of torque, speed control, and high efficiency makes them a dependable choice across a wide range of industries.

BeUDMKE’s range of brushless DC motors and brushless servo motors are designed to meet these industrial needs: from factory lines to robotics, medical devices, and beyond.

Let’s explore how these motors are applied across different sectors.

Industrial automation

Factories rely heavily on DC motors because they’re easy to control and provide consistent torque. They power conveyors, material feeders, and automated arms that need smooth, predictable motion.

DMKE’s brushless DC motors are built for this kind of work. Their compact size (compared to large motors) and high torque destiny make them ideal for equipment that runs continuously.

For applications that need tight feedback and repeatable accuracy, BeUDMKE’s brushless servo motors provide advanced motion control with quick response and stable positioning.

Automotive and electric cars

The automotive industry has been one of the biggest adopters of DC motor technology. From simple functions like window lifts and seat adjustments to advanced systems like electric steering and drive units, DC motors are everywhere.

In electric locomotives, brushless DC motors play a major role because they deliver high torque with low maintenance. Their high efficiency and quick response make them ideal for traction and auxiliary systems. Even hybrid vehicles use DC motors for control systems, pumps, and fans that support the main drive.

As designs move toward lighter and more efficient vehicles, the demand for compact, high-performance brushless motors continues to grow.

Medical devices and laboratory equipment

In medical and lab environments, precision and quiet operation matter more than raw power. DC motors are used in pumps, imaging equipment, testing machines, and small automated instruments.

DMKE’s brushless motors, in particular, are preferred here because they don’t create electrical noise and don’t need regular servicing. Their smooth motion also helps reduce vibration, which is important for sensitive instruments like centrifuges and diagnostic scanners.

Reliability is crucial in healthcare systems, and modern DC motors help ensure consistent performance during continuous operation.

Aerospace and defense

In aerospace and defense, every gram and every watt counts. DC motor designs, especially coreless and slotless types, are used where precision, speed, and low weight are essential.

They drive actuators, control surfaces, and onboard systems that have to perform in extreme conditions. Their ability to operate reliably at high altitude or under vibration makes them a trusted option for both flight and ground-based defense systems.

In these environments, failure is not an option, which is why motors with proven endurance and thermal stability are chosen.

Consumer and commercial applications

DC motors also power many of the devices we use every day, though most people never think about them. They run in small appliances, tools, HVAC systems, and even vending electric machines.

DMKE’s brushless motors are now common in drones, power tools, and smart home devices because they’re light, efficient, and quiet. In HVAC systems, DC motors help regulate air flow more efficiently than older AC motors, reducing electrical energy consumption and noise.

For commercial systems where uptime and high efficiency matter, switching to modern DC motor technology often means lower running costs and longer service intervals.

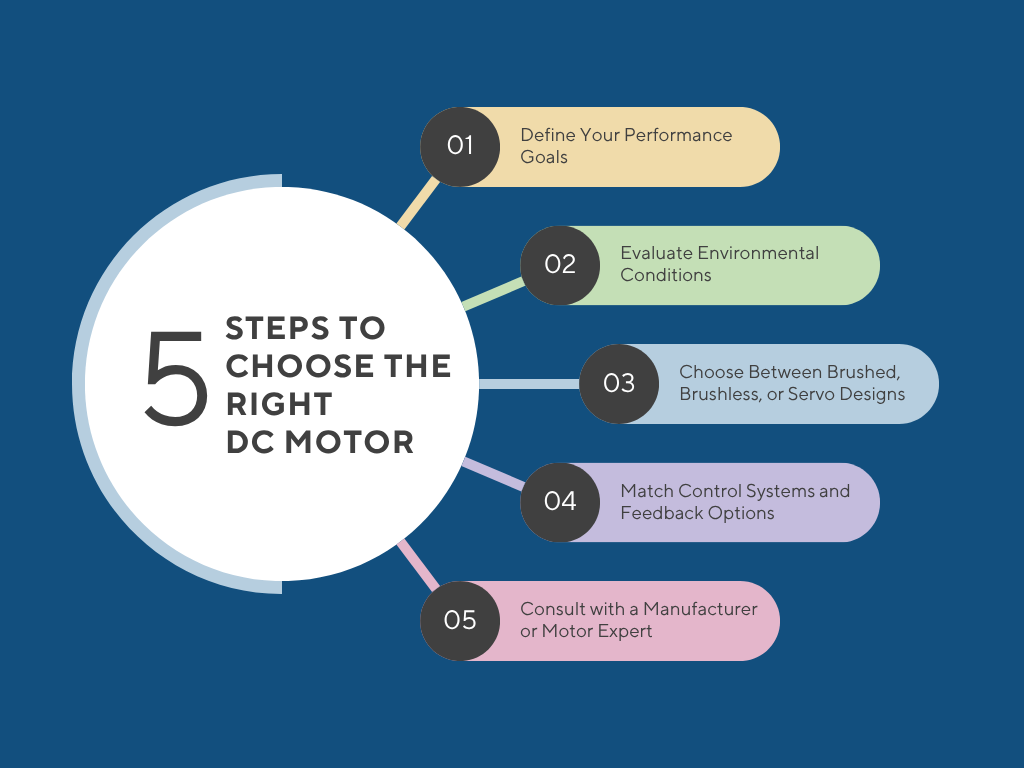

Practical steps to selecting the right DC motor

Choosing the right DC motor can feel complicated at first, but it becomes easier when you take it step by step. The key is to think about how the motor will actually be used, not just what the datasheet says.

Here’s a simple process that works well for most industrial and OEM applications.

1. Define your performance goals

Start with what you need the motor to do. Write down your target speed, torque, and power requirements. Think about how the load behaves. Does it need to move smoothly, stop often, or run continuously?

If you can measure or estimate the torque and speed under real operating conditions, you’ll be much closer to finding a good match. Always give yourself a little safety margin so the motor isn’t working at its maximum limit all the time.

2. Evaluate environmental conditions

Every environment has its own challenges. Motors in clean, air-conditioned facilities have different needs than those in dusty or humid factories. Check the temperature range, air flow, and potential exposure to liquids or chemicals.

A motor’s IP rating tells you how well it’s protected. For example, IP65 means it’s sealed against dust and can handle light water spray. If your setup involves heat, vibration, or high duty cycles, mention that to the supplier, so they can recommend the right build.

3. Choose between brushed, brushless, or servo designs

Each motor type has its place.

- Brushed motors are simple and inexpensive, good for basic tasks with limited run time.

- Brushless motors offer high efficiency and less maintenance, making them ideal for long hours and variable speeds.

- Servo motors provide the most precise control and are best for automation or positioning systems.

The right choice depends on how much control and reliability your project needs.

4. Match control systems and feedback options

If your system already uses a specific controller, make sure the motor is compatible with it. Brushless and servo motors often require matched drivers or electronic speed controllers.

Consider whether your application needs feedback. Encoders, Hall sensors, or tachometers can give precise position or speed information. In automated systems, this feedback helps the motor controller make real-time adjustments for smoother operation.

5. Consult with a manufacturer or motor expert

Even with all the data in front of you, it’s smart to talk to someone who works with motors daily. A knowledgeable supplier or manufacturer can point out details you might miss, such as motor shaft design, bearing type, or cooling method.

DMKE works closely with industrial clients and OEMs to fine-tune motor performance for their setups. Having that kind of technical support can save time and prevent costly redesigns later on.

Here are some of the services and support BeUDMKE provides during procurement:

- Custom 2D or 3D motor drawings for design confirmation

- Detailed quotation and negotiation support

- Production planning and raw material inspection

- Quality testing, packaging, and shipping

- Full after sales service

You can learn more about our support and services by visiting our “Service personnalisé” page.

Common mistakes to avoid

Even experienced engineers can run into trouble when selecting or installing a DC motor. Avoiding these common mistakes helps keep your system reliable and efficient.

1. Overlooking load inertia

Load inertia has a big impact on how a motor behaves. If the motor’s rotor and the driven load aren’t properly matched, you can end up with vibration, poor acceleration, or overshoot. When inertia is too high, the motor must work harder to start and stop, which can shorten its life.

If possible, calculate or estimate load inertia early in the design process. Servo systems are especially sensitive to this factor.

2. Ignoring duty cycle or torque ripple

Motors don’t always run at the same load all day. If your application involves frequent starts and stops, high torque bursts, or varying loads, you need to check the duty cycle rating. Running a motor at full torque for too long can lead to overheating.

Torque ripple (the small variation in torque as the motor rotates to create rotational motion) can also cause issues in systems that require smooth motion. Choosing a design that minimizes ripple can make a big difference in performance and noise.

3. Choosing based on price instead of lifetime cost

A lower-priced motor can seem attractive, but it’s rarely the best long-term option. Cheaper units may have lower efficiency, shorter bearing life, or poor heat management. Over time, that means more maintenance and higher electrical energy costs.

When you calculate the total cost of ownership, a quality motor usually pays for itself. Fewer replacements, less downtime, and better performance often add up to real savings.

FAQs about DC motors

What’s the difference between brushless and brushed DC motors?

Brushed motors use brushes to send current inside the motor. They’re simple and low-cost but need regular maintenance.

Brushless motors use power electronics instead. Therefore, they run cooler, last longer, and need less service. They’re common in automation and continuous-duty systems.

How do I find the right torque for my setup?

Torque depends on how much force your machine needs and how fast it turns. A good rule is to check both continuous and peak torque on the datasheet. If the motor runs near its limit too often, it will wear out faster.

Can DC motors run all day?

Yes, many can. Brushless and servomoteurs are designed for long hours of work. Brushed motors can too, but they’ll need brush replacement from time to time.

How long do DC motors last?

It depends on use. Brushed motors might last a few thousand hours before needing service. Brushless ones can run for years with little maintenance, especially if kept clean and cool.

What kind of motor is best for industrial use?

For most modern systems, brushless or servo motors are the better choice. They’re efficient, quiet, and built for precise control. BeUDMKE’s industrial motor range is a good example of this kind of design.

Conclusion

Picking the right DC motor comes down to understanding what your system really needs. The right match keeps your machines running smoothly, saves energy, and reduces maintenance problems.

For modern automation, brushless DC and servo motors have become the preferred options. They deliver quiet, efficient, and accurate motion that fits today’s demands for performance and reliability.

À DMKE, the focus is on helping engineers and buyers make confident choices. From design consultation and 3D drawings to production, inspection, and after-sales service, every step is built around ensuring the motor you get performs exactly as needed.

If you’re unsure which motor is best, it helps to talk with someone who builds and tests them every day. With DMKE’s technical support, you can find a motor that fits your job perfectly and keeps your equipment working without trouble.