For buyers looking to source high-quality brushless DC motors, sourcing the right solution often becomes much more complex than they anticipate. For many, challenges such as an inconsistent supply of motors with limited customisation options are typical.

There are many suppliers who claim to offer high-performing solutions. However, the same suppliers instead supply standard models that do not fully align with the requirements of the projects they are being used for. Sometimes, critical parameters like voltage, speed, and torque do not fully match the client’s expectations, which causes a lot of problems.

A mismatched unit not only leads to higher maintenance costs and downtime but also shortens the equipment’s lifespan and affects its ability to perform.

In modern industries and commercial applications, relying solely on off-the-shelf options is rarely a choice anymore. This explains why buyers are increasingly requesting customised designs that are tailored to meet their exact specifications and output needs. Customised motors often smoothly integrate into modern systems, thus increasing their demand.

However, customization itself is a huge job. It requires you to find a reliable supplier who can deliver two things at the same time: A) a fully customizable unit, and B) consistent quality across all batches. Prototyping support and a consistent supply chain for low minimum model quantities are other issues many industries face when getting customized brushed DCs.

A high-quality DC unit with brushes is not defined only by power output. Rather, how such a motor seamlessly integrates into the system also matters, along with its long-term reliability. You need to find a supplier who can provide you with your desired units.

Le supplier should also be capable and must ensure quality in elements, including brushes, commutators, and thermal management systems. All of these things are almost impossible to achieve without the right expertise.

Ensuring speed control and accuracy in custom solutions, along with a long service life, is almost impossible to achieve. It is only if you find engineers who are experts and truly know their job that you can confidently pursue customisation.

All of this is why buyers are urged to look only for reliable names, especially when they want a solution tailored to their needs. With the continuous increase in the industry’s demand for application-specific brushed DCs, more and more manufacturers are jumping into offering custom support. However, not each of them is reliable. Hence, we suggest you do your motorised projects a favour by trusting DMKE for all your OEM and ODM needs. Below is a detailed account of brushed DC’s qualities and what makes DMKE a top choice for customisations. So, read on:

What Makes a High-Quality Brush Motor DC

Before industry experts and procurers can order a customizable DC solution, it is important to understand a few things. One must be aware of the elements that make any solution a high-quality one and help it stand apart from classic options. Below are some of the things that a motor must possess in order to qualify as a high-quality option for industrial automation:

1. Electrical Efficiency and Power Stability

A high-quality brushed DC is one that delivers stable electrical performance regardless of changes in external load. Efficient current flow, minimal loss of energy, as well as consistent voltage handling are the stability determiners of the unit.

A DC unit that displays all such qualities with a stable power output is the one that will operate smoothly without sudden drops or poor electrical performance. In the absence of such stability, the solution can easily jitter, overheat, and eventually stop working. This makes such motors unfit for commercial use.

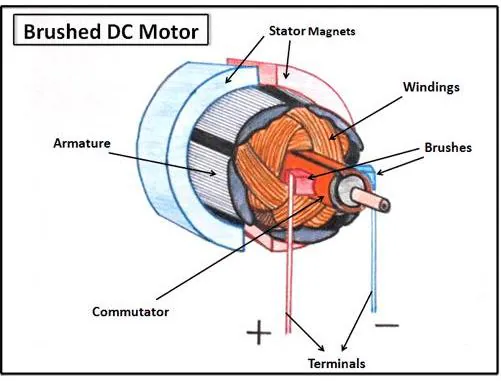

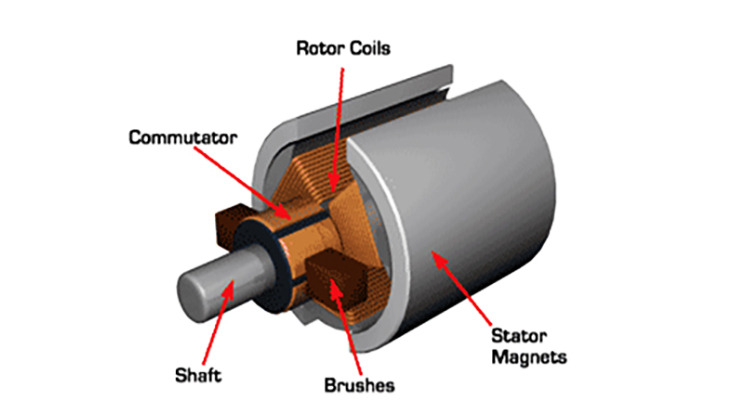

2. Brush and Commutator Material Quality

In brushed setups, the quality of internal components, such as brushes and commutators, determines the overall efficiency and lifespan of the setup. High-grade carbon brushes and properly machined commutators exhibit reduced friction, less sparking, and less wear during operation. Compared to this, motors with inferior-quality brushes and commutators often result in unstable and jittery operation. Ultimately, premature failures are common in such units.

3. Torque Consistency and Speed Control

It is very important for your brushed DC setups to ensure consistent couple output along with reliable speed control. For DCs, maintaining consistent torque and speed is only possible when they are designed with precise windings and have balanced magnetic fields inside them. All such features ensure that the motor will remain stable even during fluctuating loads and changing external conditions.

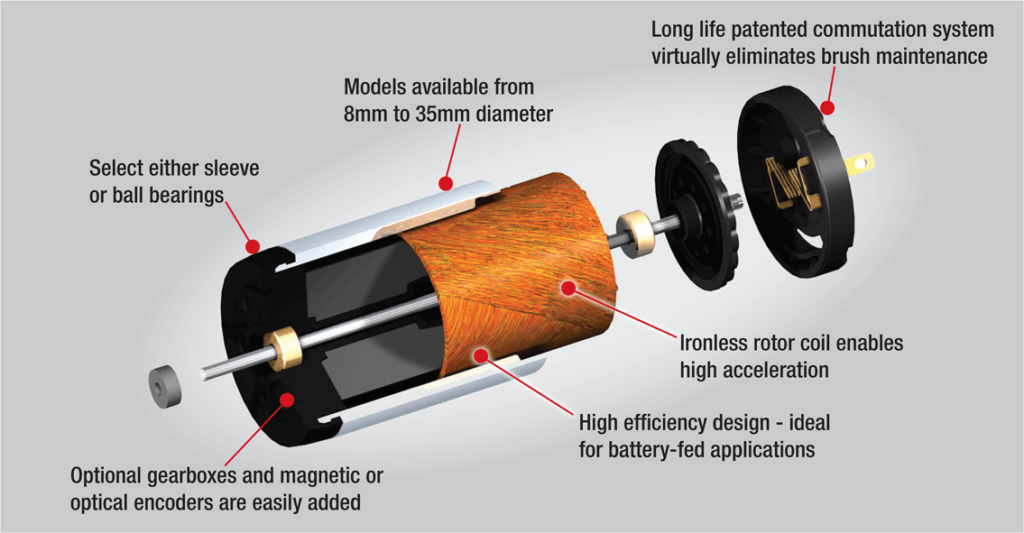

4. Thermal Management and Heat Dissipation

Since friction and the conversion of energy into heat are two unavoidable downsides of brushed DCs, effective heat dissipation is the only solution to ensure their reliability. A well-engineered and well-made high-quality brushed DC solution will always have an optimised ventilation system, along with some form of heat sinks.

There must be proper insulated materials inside the setup, capable of withstanding high temperatures. In the absence of proper thermal management, a DC setup can degrade and exhibit internal damage to its components, thus becoming unfit for use. Such poor systems are often unsuitable for industrial usage.

5. Mechanical Strength and Vibration Resistance

A defining feature of any high-quality brushed DC setup is its robust mechanical strength. Motors with strong housings, precision bearings, and proper alignment of shafts will always show minimal vibration. This reduced vibration not only enhances overall stability but also protects the surrounding equipment. This way, it reduces the setup’s exposure to unnecessary mechanical stress.

6. Service Life, Maintenance, and Reliability

A high-quality unit will always have a long service life and ensure dependable operation. A DC with high-quality brushes will have reduced maintenance intervals and will lower the overall downtime of your working setup. This stability in performance and reduced wear also minimises the total ownership costs of such DCs. Such reliability is especially important for industrial users, where downtimes are almost non-negotiable.

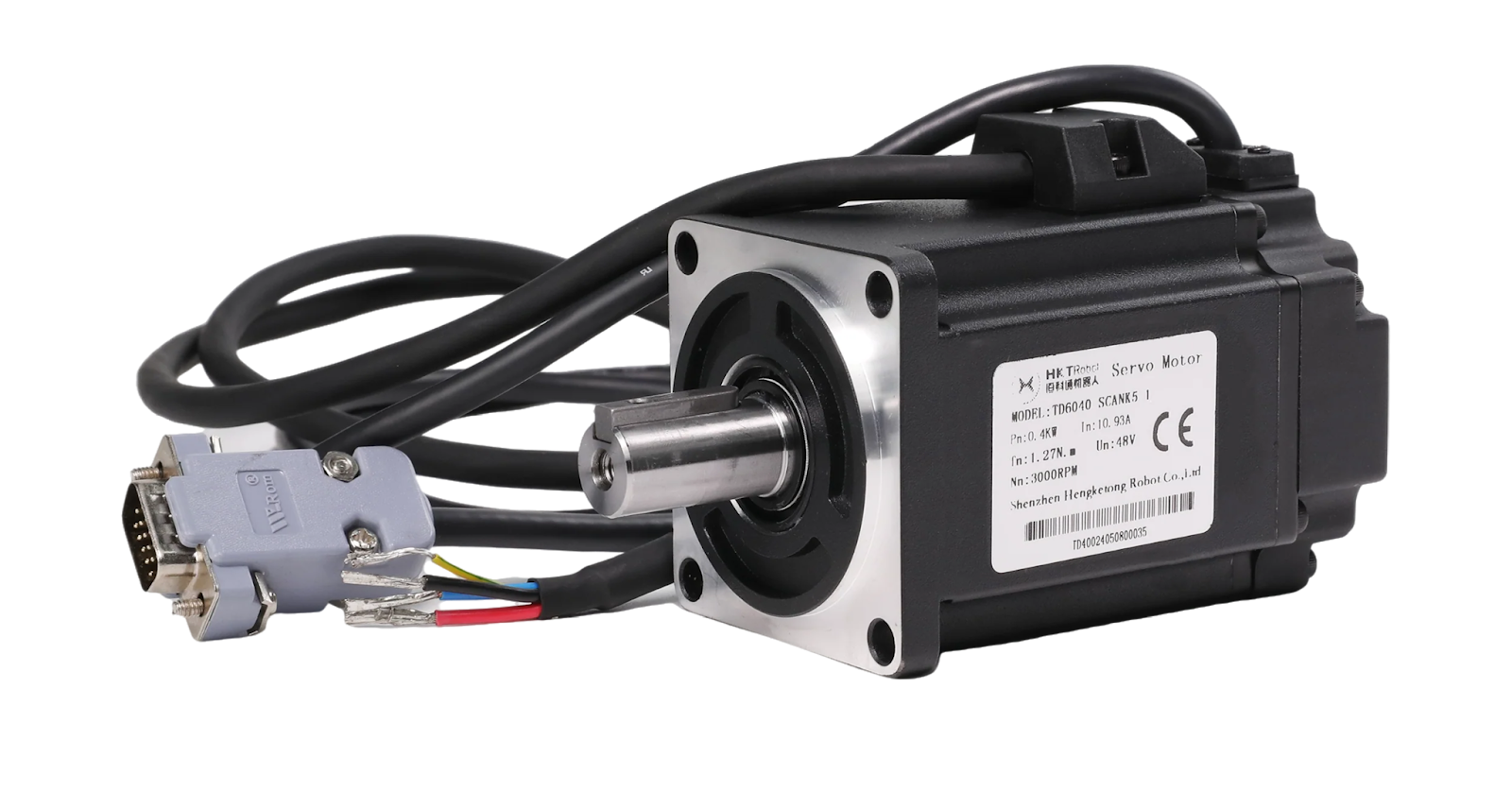

DMKE Brush Motor DC Product Range

À DMKE, we have a comprehensive range of brushed DC solutions, designed specifically to meet the diverse needs of all our users. Our solutions are not only ideal for industrial users but also serve commercial and OEM applications, as well as individual users, equally.

Our diverse product portfolio ranges from standard ready-to-sell models for general users to high-torque and heavy-duty options. Each of our products is developed with a focus on stable output and performance, along with a long service life and a strong commitment to excellence.

Our options are suitable for continuous operation as well as intermittent duty cycles, without requiring extensive maintenance or manual integration. DMKE’s brushed DC range comes with multiple voltage ratings, speed ranges, torque outputs, and power requirements. This allows buyers to select a unit that perfectly aligns with their application needs.

In cases where an application demands a specific integration that is not readily available, our engineers are ready to consult and carry out detailed evaluations. We conduct in-depth research to ensure the development of new solutions that suit our clients’ exact requirements.

DMKE’s brushed DC lineup is developed with scalability at its core. We support both small-batch production and large bulk-volume supplies. Ensuring consistent quality across all batches is what has earned us a strong name in the industry. Our engineers are capable of producing units that integrate smoothly into systems and maintain uniform performance over years of operation.

Custom Specifications & OEM/ODM Options

Whenever you have to source a brushed DC solution for specialised industrial usage, customisation is something you need from your supplier. At DMKE, we provide extensive OEM and ODM support to all our clients, regardless of the nature of their requirements. Whether you want to source in bulk for projects spanning over years or simply want a custom solution with a low minimum order quantity, we serve all needs equally.

Our engineers and experts are always ready to assist. Buyers can customise essential motor parameters such as voltage, torque, speed ratings, shaft designs, and more, exactly according to their requirements. We also provide tailored mounting configurations and motor dimensions so that the motors can integrate precisely into your applications.

Alongside this, we offer expert-level customisations with enhanced encoding and integration capabilities. You can trust us for cases that require in-depth research and engineering support for a motor to be incorporated into a dynamic setup.

Our OEM services allow customers to modify existing brushed DC solutions while maintaining their core design to a certain extent. This approach helps us preserve our carefully curated core motor platforms while adding custom specifications, thereby reducing overall development time and cost.

For more specialised requirements, our ODM solutions offer complete motor development for clients. This process includes motor conceptualisation and prototyping and extends to final bulk production. Our ODM solutions are particularly valuable for pilot projects, new products, and highly specialised industrial applications with unique performance and space constraints.

In addition to technical customisation, we also support low minimum order quantities and rapid prototyping. This enables buyers to test products before finalising bulk orders and scaling production.

Our relationship with clients goes beyond simply selling motors. DMKE’s post-sale engineering support and installation assistance help ensure proper integration and smooth operation. This reliability and customer service make DMKE a trusted name in the motor manufacturing world and an ideal partner for long-term OEM projects.

Applications of Brush DCs Across Different Industries

Brushed motors working on direct current have been around for decades. These motors are used in various small and large applications across different industries. Below are some of the most common industries that cannot work without the presence of brushed DCs:

Industrial Automation and Machinery

Brushed DC solutions are widely used across marketable industrial automation equipment. Here, these ensure reliable torque and speed control and efficient operation. You can find DCs commonly powering conveyors, actuators, small CNC machines, packaging machines, and other systems where consistent performance and easy integration control are essential.

Automotive and Mobility Equipment Systems

In automotive and mobility systems, brushed motors provide power automation for components like power windows, seat adjustments, pumps, auxiliary drives, and more. Their compact size makes them efficient for systems where dependable motion control with moderate power is required.

Medical Devices and Healthcare Equipment

Medical equipment relies heavily on brush DC solutions for precise and smooth operation, especially in small equipment like diagnostic devices, medical pumps, rehab equipment, and other lab instruments. In short, these devices help with the accurate, reliable, and controlled motion of the equipment.

Home Appliances and Consumer Products

Brush technology is extensively used in home appliances like vacuums, mixers, kitchen equipment, and personal care items. Because of their ability to deliver stable performance with controlled speeds, they are ideal for everyday consumer goods that have to work through continuous hours.

Key Benefits of Choosing DMKE Brush Motor DCs

Choosing DMKE to purchase or customise brush DC for your needs is one of the best decisions you will ever make. Our comprehensive engineering and development team is capable of ensuring support for our clients at every step. Whether you want a setup for generic use or something that meets application-specific requirements, our R&D team can assist you with the right motor selection.

Our research and development team can help you shortlist the best motor options for you. We can also help you with the customisation and optimisation of existing solutions or when you need to develop new solutions from scratch.

Our seamless manufacturing process relies only on premium and high-quality materials at all stages. Each brush solution from DMKE uses only high-quality elements inside and is built using strict manufacturing standards. Whether it is high-grade brushes, durable commutators, or strong motor housings, each element of our motors is capable of delivering long service life and exceptional sturdiness.

DMKE does not forget to balance quality with costs. All our motorised solutions, including DCs, servomoteurs, BLDCs, and others, are a perfect blend of cost-effectiveness and high performance. This makes us your ideal supplier for both short-term projects with low minimum order quantities and large-scale projects that need consistent supplies.

DMKE provides full flexibility whenever our clients want to customise their motors. Whether you want changes in voltage, torque, speed, or simply want a solution with dimensions that suit your application, we can do it all. This adaptability of our services ensures that all our clients get the best solutions while having to make zero compromises on their preferences.

Our reliable global shipping services, along with scalable manufacturing capabilities, make us one of the best names in the industry.

How to Choose the Right Brush Motor DC for Your Project

Choosing the right brushed DC solution for your project or getting it customised from DMKE is very simple. Simply follow the steps below to get your desired solution:

Step 1: Defining Your Requirements

Firstly, you have to clearly identify the function and purpose that you want the motor to serve. For this, you need to define the duty cycle as well as the load type that the setup will face. You also need to be clear about the required speed and torque ratings, along with the size of the setup. Understanding the external environment and the conditions in which the setup has to work also helps you clarify your needs at this stage.

Step 2: Evaluating Electrical And Mechanical Requirements

Once you have defined your application requirements, you need to assess critical parameters like voltage rating, current limits, and efficiency. You must also consider the mechanical factors you prefer in your motor. These include defining the shaft type, mounting style, and physical dimensions. Properly matching the electrical and mechanical parameters ensures that the motor will smoothly integrate into your overall setup.

Step 3: Consultation And Prototype Development

Once you have clarified all your requirements with our research and development team, we will begin designing a prototype. After the design is finalised, the engineering team will physically produce that prototype for you to test and integrate into your application.

Step 4: Validating Performance And Bulk Production

Once you validate the performance of the setup, our team will start bulk production of the solution. Each production will be followed by rigorous QA testing of each unit, while ensuring smooth supply and reliable shipping.

Partner with DMKE for Reliable Brush Motor DCs

Want to enhance your systems with high-performance brushed DCs? Partnering with DMKE is one of the best decisions you can make!

Whether you want precision-engineered solutions ready for sale or want to customise your solutions with a more flexible setup and system settings, we have it all. At DMKE, our engineers are capable of developing single prototypes for your needs. Along with this, we can also support you with bulk requirements.

Each and every solution that we produce is made only with high-quality components manufactured using precision engineering. Each and every solution that leaves our factory undergoes rigorous 8-step testing. This ensures that whatever we offer meets the highest standards of quality.

Visit our website today. Our research and development teams are ready to consult with you on your requirements. Our engineering teams cannot wait to develop a solution that suits you in the best possible way. Connect with us now to start discussing and sourcing the right motors for your needs.