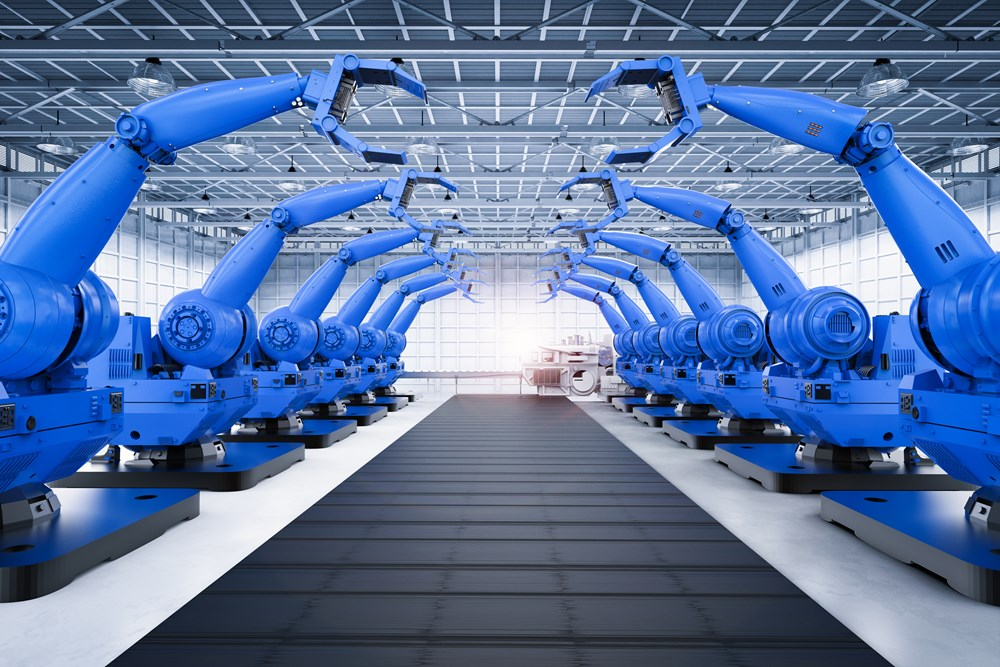

The modern world’s industrial automation is evolving at a very fast pace. However, issues like insufficient positioning accuracy, non-compliant torque, and high maintenance costs remain a big challenge for industries.

Talk about robotic lines, want to manufacture automated guided vehicles, or food packaging machines. Modern industries now demand nothing but accuracy, performance, and speed. Anything that delivers less than reliably is considered a fail.

This is where several servo solutions come in, offering precision and accuracy without any extra maintenance demands. At DMKE, we have been manufacturing reliable automated industrial and motion control solutions for the past 15 years. Among many of our offerings are the best quality servos. These are made to provide efficient power to the next generation of automated systems.

Originating in Guangzhou, China, our commitment to excellence and quality is what drives everything that DMKE does. At our manufacturing plant, we have been combining advanced R&D with a strong global supply chain.

Our solutions have been serving industries across Europe, the US, the Middle East, and Asia. We offer a comprehensive range of products, including DC servos, hub servos, frameless servos, planetary servos without gearboxes, and deep servos with planetary gearboxes.

Each of these offerings is aimed at bridging the gap between industrial automation requirements and precision. All of our devices are built to meet the overpowering and demanding requirements of automation.

The Importance Of Servo Motors In Automation Industries

As we have already stated, servos work as the backbone of any modern automation system.

Compared to the conventional and standard motors that spin at a fixed speed, servos work differently. They can deliver accurate motion control along with precise positioning and torque. They do this while offering seamless feedback to the system. This makes them ideal for industries where accuracy and timing control are everything.

These motors stand apart from others on the basis of their closed-loop system. Using this system, it is capable of monitoring itself under feedback from sensors and maintains the exact power and speed output required from it.

This system makes sure that all the movements and positionings are executed correctly with zero compromises made on precision.

Below is a table comparing servo motors with stepper and induction ones.

| Feature | Servo | Stepper | Induction |

| Control System | Closed-loop with feedback | Open-loop | Open-loop |

| Precision | Very high (micrometre-level) | Moderate | Low |

| Speed Response | Instant and dynamic | Slower | Fixed speed |

| Torque at High Speed | Stable and strong | Drops significantly | Moderate |

| Energy Efficiency | High (adapts to load) | Moderate | Lower |

| Noise & Vibration | Minimal | Noticeable | Moderate |

| Best Use Case | Robotics, CNC | 3D printers, simple positioning | Fans, pumps, conveyors |

Practically speaking, servos can ensure seamless automation in the following ways:

- They ensure real-time motion control for robotic arms and conveyor belts.

- They are capable of supporting synced operations in systems that operate with multiple axes.

- They are able to ensure reduced downtime in industries because of their efficient power and energy consumption.

These motors combine and blend effortlessly with drives, PLCs, and other motion controllers. This allows the factories to focus more on adaptive technologies and processes. This also helps industries automate processes and reduce the need for manual intervention.

As a result, they help the industries become more flexible and offer more productivity with reduced costs and reliability. To sum up, this motor is not just a simple machine component; it is rather the brain of every intelligent automatic system.

Top 5 Servo Motor Solutions for Industrial Automation

The engineers at DMKE have mastered versatility in servo solutions. We understand that every machine has different needs and demands to fulfil. This is why we’ve created distinctive servo solutions, serving distinctive needs.

Below is a detailed description of our top five servo motor solutions that high-tech engineers and stakeholders love:

1. DC Servo Motor without Gearbox

For applications that require accurate torque and smooth speed control, DMKE’s DC Servo Motors without a Gearbox are ideal. These are designed to be compact yet powerful to give advanced motion control.

The reliable performance delivered by these when used in industrial equipment like AGVs, robotic arms, medical devices, and much more makes them worth investing in.

Key Specifications

The primary specifications are:

- Flange Size: 40mm – 180mm

- Rated Power: 50W – 10KW

- Voltage Range: DC12V – DC310V

- Torque Range: 0.159Nm – 48Nm

- Speed Range: 100rpm – 3000rpm

There are several reasons why this one is preferred by customers over other servo solutions. It integrates smoothly into complicated systems and offers adjustable power and voltage options for use in different cases. This motor also provides a high torque-to-size ratio for efficient position-based control.

2. DC Servo Motor with Planetary Gearbox

Want maximum torque output, that too without reducing precision? If yes, then the DMKE’s DC Servo Motor with Planetary Gearbox is the perfect solution. This servo motor promises performance with improved load-bearing, making it ideal for robotics, industrial automation, and material handling devices.

Key Specifications

The main specs of this servo motor are listed below:

- Gearbox Flange Size: 42mm – 242mm

- Rated Power: 50W – 10KW

- Voltage Range: DC12V – DC310V

- Torque Range: 0.5Nm – 4420Nm

- Gear Ratio Options: 3 – 250

There are plenty of reasons why engineers choose this motor. A major reason is that it is perfect for applications that require an increase in torque and a reduction in speed, and offers High torque transmission with precise motion. It also delivers excellent motion stability even at low speeds.

DMKE’s DC Motor with Planetary Gearbox is designed for the durability and precision that are mandatory in industrial applications.

3. Rolling Door Servo Kit

This Rolling Door Servo is particularly designed for intelligent door control systems. Whether for commercial or industrial-grade rolling doors, this motor delivers smooth, quiet, and reliable performance.

The power capacity, combined with the smart motion control, lets this motor handle different weights and sizes while ensuring safe lifting. Lastly, the quiet operation makes this motor ideal for offering an excellent user experience.

Key Specifications

The features of this motor that impressed stakeholders include:

- Rated Current: 3A – 6A

- Rated Power: 750W – 2.2KW

- Voltage Rating: AC220V

- Lifting Weight Capacity: 50KG – 150KG

- Supported Door Size: 10M² – 50M²

This motor features intelligent torque control to guarantee a safe and secure door movement. Additionally, the motor offers a smooth operation while producing minimal noise. This smart, silent, and strong motor is designed to support almost all commercial and industrial rolling doors. All these points and reasons make choosing this servo motor a wise choice.

4. AC Servo

From CNC machinery to auto packaging systems, DMKE’s AC Servos are suitable for all applications. With its robust design and low maintenance feature, this motor provides reliable motion control in high-performance operations.

Combining accuracy, precision, rapid response, and energy efficiency all together, this motor is perfect, no matter whether you’re manufacturing a multi-axis robotic arm or upgrading a conveyor system.

Key Specifications

The key features of this option are:

- Flange Size Options: 40mm – 180mm

- Rated Power: 50W – 7.5KW

- Voltage Rating: AC220V

- Torque Range: 0.159Nm – 48Nm

- Speed Range: 1000rpm – 3000rpm

What makes this one a great choice is that it is fine-tuned for high-speed positioning systems. It also needs lower maintenance as compared to DC systems. It is also compatible with multiple controllers.

It is reliable, customizable, and is designed to add efficiency and intelligence to your motion systems.

5. DC Servo with Worm Gearbox

DMKE’s DC Servo Motor with Worm Gearbox is designed for applications that demand high torque but have a compact design. This one is perfect for lifting equipment, turntables, conveyor systems, and other systems where accuracy is crucial but space is limited.

The gearbox worm offers excellent load capacity and a steady motion. Additionally, the integrated worm reducer delivers the optimal torque multiplication and enables a self-locking feature, adding a layer of safety.

Key Specifications

The main specs of this option include:

- Gearbox Size Range: RV25 – RV150

- Rated Power: 50W – 10KW

- Voltage Range: DC12V – DC310V

- Torque Output: 0.5Nm – 1000Nm

- Gear Ratios Available: 7.5 – 100

Choosing this compact motor is a wise decision because it offers high torque output. It has a self-locking feature for equipment safety and is perfect for heavy-duty and low-speed applications.

| Motor Type | Torque Range | Power Range | Voltage Rating | Gearbox Type | Ideal Applications |

| DC (No Gearbox) | 0.159Nm – 48Nm | 50W – 10KW | DC12V – DC310V | None | Robotics, medical devices, compact systems |

| DC + Planetary Gearbox | 0.5Nm – 4420Nm | 50W – 10KW | DC12V – DC310V | Planetary | AGVs, automation lines, material handling |

| Rolling Door Servo Kit | Lifts 50KG – 150KG | 750W – 2.2KW | AC220V | Motor Kit System | Industrial doors, garage systems |

| AC Servo Motor | 0.159Nm – 48Nm | 50W – 7.5KW | AC220V | None | CNC systems, packaging lines, and multi-axis robots |

| DC + Worm Gearbox | 0.5Nm – 1000Nm | 50W – 10KW | DC12V – DC310V | Worm | Lifts, rotating platforms, compact conveyors |

What Matters The Most In Servo Motor Systems: Selection Guide

With so many systems and options available, it can be hard to choose the right ones for your needs. When choosing a servomotor, you can’t just look at performance in terms of torque or speed.

Rather, the true essence of a servomotor lies in its precision and how it can convert signals into motions. Moreover, consistency, efficiency, and load conditions are also some important factors to consider when investing in a good system.

Engineers who want to achieve robotic accuracy and streamlined production must look at and understand the key features of every servomotor solution. It is because these features make all the difference in its performance and the overall system’s working. Some features to consider are as follows:

1. High Torque Density: If you want your machine to handle heavy loads without compromising on the efficiency of the work, then you ned high torque density. In other words, you want your servomotor to deliver strong torque from a compact housing to a bigger machine system.

2. Position and Speed Feedback: Several servomotors come with encoders integrated in them, along with these, there are resolvers too. These integrated systems can constantly monitor the positioning and speed, providing real-time feedback to the motor for enhanced accuracy.

3. Energy Efficiency: These motors are capable of adjusting power consumption based on load.

4. Response Time: You want your solution to react instantly to the feedback. This will control inputs to maintain synchronization.

5. Noiseless Working and Low Vibrations: In industrial, medical, and several other industries, a servomotor with smooth and quiet operation is crucial.

6. Compatibility and Integration: A servomotor system that is capable of seamlessly communicating with PLCs and other networks is the one that will ensure flexibility and scalability for future upgrades.

In our advanced servomotors, all the above features are present at their best. This makes servomotors by DMKE not only over-precise but also reliable and intelligent, and can self-reflect on performance with a strong feedback system.

Controller’s Role In Servo Output Precision

The controller of any motor is its unsung hero. It is the unseen force behind that makes all the difference in its power and precision. The controller transforms electrical energy into mechanical movement while keeping precision and performance intact.

The controller will interpret command signals as well as monitor the feedback that’s coming. Based on the data gathered, it will continuously adjust voltage and current to maintain the exact movements in the machine.

For any servo motor to perform its best, seamless communication between it and its controller is extremely important. This communication and its timing are all that make a difference in the automated performance.

At DMKE, we have motors with controllers that will complement the ranges perfectly. Our products ensure coordination and responsiveness at their best. In a closed-loop control in a servo motor, both the controller and the motor will work perfectly in sync. This will correct the smallest deviations instantly, reduce downtime, and minimize energy wastage.

Future Trends in Servo Technology

Since the end of the last decade, industries have been continuously evolving to embrace AI transformation. This evolution has enhanced the importance and usage of technology along with its evolution.

It is anticipated that the next generation of servo solutions will be shaped by innovation and progress in data analytics, connectivity, and energy efficiency. The next generation will also be aimed at sustainability while ensuring smartness and adaptable machinery.

In the past few years, a significant shift in the servo technology has been the rise of smart systems. These are equipped with built-in sensors as well as IoT capacity. Such smart solutions are capable of collecting and transmitting real-time performance data.

Along with this, they also allow the machine to perform predictive maintenance and fault detection. These smart systems prevent unplanned downtime and increase productivity. They are also able to extend the overall lifespan of the industrial automation system.

Recently, a key trend has been noted regarding the integration of AI-driven control algorithms in motors. Machine learning is being efficiently utilised by the manufacturers. It helps optimise the motion profile as well as the responsiveness. This AI-driven algorithm has helped produce motors with reduced vibration and noiseless operation.

These smart motors are capable of dynamically adjusting to the consistently changing loads and external conditions. This improves their accuracy and makes them capable of use in the toughest environments as well.

Among everything else, energy efficiency still remains the topmost priority for all systems. Manufacturers are trying to design a motor that can recover and reuse energy in a regenerative manner. Such motors are anticipated to cut power consumption and support global sustainability goals.

Global Industries Trust DMKE And You Should Too

For a business to gain trust in automation is something that doesn’t happen overnight. This trust is rather earned through consistent performance and years of innovation and reliability. Thankfully, over the past 15 years, DMKE has been able to develop such a level of trust globally.

This is all because of our reliable motion solutions that are made under stringent quality standards. Each and every solution that we produce comes to life after rigorous designing, testing, and quality checks. Whether it’s about dimensional checks or no-load to full load inspections, every stage is monitored.

Our professionals ensure compatibility while making no compromise on precision and reliability. Our commitment to excellence is then reinforced by ISO 9001 certifications. All of it proves that the quality is not just our promise but a standard that we never let go of.

Our network goes beyond Europe, North America, the Middle East, and the Asia-Pacific. This shows how we have gained the trust of a truly international clientele. This is all because of our technical support engineers and laborers, who are trained to ensure perfection in all aspects of our manufacturing processes.

Conclusion

Now, seamless automation is defining most of the industrial operations. This is why the role of motors is becoming more important and crucial than ever. At DMKE, we are keeping precision, power, and control as our most important defining features for each of our servo solutions.

If you’re an engineer or industry stakeholder who wants upgraded performance that speaks for itself, get in touch with us today!

Connect with our experts so we can discuss and understand your requirements for a system. It is time for you to get power and reliability like never before.